Nuclear workers see risks as conditions worsen

By Reuters

Protective Relay Training - Basic

Our customized live online or in‑person group training can be delivered to your staff at your location.

- Live Online

- 12 hours Instructor-led

- Group Training Available

When such complaints arise in France's most sensitive industry — nuclear power — alarm bells start ringing.

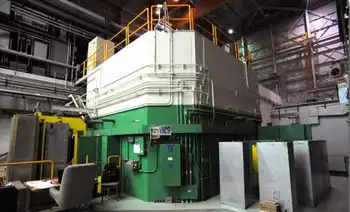

Cyril Bouche and his colleagues at the Tricastin nuclear plant in the rolling hills of the Drome region say the state-owned utility EDF, which runs France's 58 nuclear reactors and has been expanding into the United States and Britain, is not only cutting costs, but also cutting corners.

The 39-year old, who works for one of EDF's many subcontracting firms, says working conditions at the plant — hit by a series of incidents that shook public trust in 2008 — have deteriorated over the past five to 10 years.

"Today France is selling reactors abroad but it should first put its own house in order," said Bouche, the only one of 10 workers interviewed by Reuters who was prepared to be identified.

The French government has put forward state ownership of its nuclear sector as a guarantee of its safety, but former monopoly EDF subcontracts 80 percent of the maintenance at its nuclear reactors to firms such as Vinci, Areva, GDF Suez or Bouygues.

EDF denies the suggestion that subcontracting implies it is skimping, pointing to plans to more than double investments to 8 billion euros in 2009 from 2005 levels to build and modernise nuclear, fuel-fired power plants and hydraulic plants.

"We subcontract because we have very specialized activities. When we change the reactor's fuel, this is a very sophisticated activity," said Philippe Gaestel, head of industrial strategy at EDF.

"We prefer to use subcontractors rather than do it ourselves. This means we have specialists and competencies that we couldn't have internally."

But independent experts including Yves Marignac, executive director of the information agency Wise-Paris, say safety margins in French nuclear power plants are shrinking as plants age, economic pressure mounts and trained staff retire.

"Even if it remains very unlikely, the probability of a serious nuclear incident is rising because of the way things are evolving, and this in itself is very worrying," he told Reuters by telephone.

France's nuclear safety record worsened in 2008.

Last year there was an increase of nearly one-third in nuclear incidents reported by the French nuclear safety watchdog at level one of the International Nuclear Event Scale (INES), which runs from 0 to 7.

The French nuclear safety board ASN said there had been 72 incidents at level one in 2008, up from 56 in 2007.

Nuclear is the main industrial sector of the Drome region famous for the nougat delicacy made in the city of Montelimar.

"All in all nuclear must make up between 75 and 80 percent of the region's employment," said Guy Durand, deputy mayor to the town of Pierrelatte, one the three cities which share the nuclear site of Tricastin.

"It's enormous... today there are around 5,000 permanent jobs on the industrial site," Durand added.

For Bouche and others, good pay was the lure to an industry that requires working long hours in dark and confined spaces with the constant risk of exposure to radiation.

A former car mechanic on the minimum wage, Bouche said he doubled his salary when he entered the nuclear sector 18 years ago but that pay had not increased with inflation.

France generates 80 percent of its electricity from nuclear power and is keen to export its expertise, which stretches back three decades, as other countries turn to nuclear to cut carbon emissions and boost their energy independence.

It opted for nuclear after the 1973 oil crisis pushed oil to then-record levels, although the choice was political: the costs of nuclear and fossil fuels are not easy to compare.

Thanks to state intervention in pricing, French consumers pay one of the cheapest rates for electricity in Europe. The French public continued to back the expansion of the industry after the explosion of the Chernobyl nuclear reactor in Ukraine in 1986, as other countries turned their back on the technology.

But as media attention mounts on atomic energy and France plans to extend its reactors' lifespans and build new ones, public acceptance is diminishing.

A 20-country survey earlier this year by Accenture showed that while public resistance to nuclear power had eased in many countries in the last three years, French consumers had become more negative.

The Tricastin workers say they are worried about mounting numbers of small incidents, and point to a lack of oversight.

"In the past we used to work hand-in-hand with EDF on maintenance operations, but little by little EDF has withdrawn to let subcontractors take over," said one of Bouche's colleagues, speaking on condition of anonymity because he feared he may lose his job.

"Now EDF has lost its knowledge," he said, adding that EDF agents now merely played a monitoring role.

Annie Thebaud-Mony, head of research at the French health institute Inserm, said jobs in nuclear power plants were becoming less secure due to privatization and competition.

EDF partially floated its stock in 2005. Core profit for 2008 fell by more than 6 percent to 14.24 billion euros, and the company pledged in February to focus on organic growth after acquisitions in Britain and in the United States inflated its debt to nearly 25 billion euros.

But the company denies it has gradually pulled out from maintenance, saying it chose to subcontract from the outset.

"This was the optimal option to have quality work with specialists who operate permanently on our sites," said EDF's Gaestel. He said the company spent some 1.5 billion euros annually on maintenance, a relatively stable sum for some years.

Bouche and his colleagues say maintenance periods have considerably shortened. Each planned outage costs EDF around 1 million euros per day, the company has confirmed.

"Before, it took two months to do standard refuelling maintenance against three to four weeks now," said a logistics manager who heads a team of 30 and has been in the sector for 22 years.

EDF, which sells electricity to its neighbors, is under pressure to increase the availability of its aging reactors.

EDF's Gaestel said it was important for the operator to stick to its maintenance program drawn up in advance.

"What can be a problem though is when the planning drifts because of technical problems, like at the Tricastin nuclear site in 2008," he said.

France's nuclear watchdog ASN said in its 2008 report that maintenance operations were not always satisfactory because of inappropriate documentation, insufficient protective equipment and too tight a schedule.

It said subcontractor training should be improved.

For the workers, the tight maintenance schedules are adding to the risk of accident.

"We work on top of each other in the nuclear reactor which is very narrow and where it's hard to operate," said a 53-year-old worker. "We can be hit on the head by a hammer or be contaminated. Before, those risks did not exist because we used to take it in turns to work," he said.

While EDF agents have public sector contracts, which means a job for life, subcontractors fall in the private sector, making them vulnerable to job cuts. Their firms risk losing their contracts with EDF every three years.

EDF said not just any company could work in the nuclear sector.

"You have to produce your credentials to work in the nuclear field," Gaestel said. "Before a company can apply to our tenders there is a six-month long audit," he said, adding EDF planned to extend current contracts with subcontractors to six years.