World demand driving mining resurgence

By Knoxville News Sentinel

CSA Z463 Electrical Maintenance

Our customized live online or in‑person group training can be delivered to your staff at your location.

- Live Online

- 6 hours Instructor-led

- Group Training Available

Instead, King Coal has made a remarkable recovery in East Tennessee since industry prices hit rock bottom in 2000 at $25 a ton, making mining too expensive for all but the operators with the deepest wells and pockets.

Less-than-scientific economic indicators of an industry on the rebound are all around: fully loaded coal hoppers are leaving the area via Norfolk Southern and CSX in greater numbers; more coal-hauling big rigs are running the roads in mining counties; more job postings are appearing seeking miners; and stock prices of major coal companies are 1,000 percent higher than eight years ago.

Not-so-anecdotal evidence also is apparent. The U.S. Office of Surface Mining reports that in 2000 there were applications for mining permits. In 2007, that number was up to.

The resurgence also is being felt in Southeast Kentucky, Southwest Virginia, West Virginia and North Alabama, states with especially heavy mining activity.

So, what's stoking this renewed interest in America's most abundant fuel source?

Despite being strictly regulated and a favorite target of environmental protests, coal is in favor again because of world demand. The United States' attempt to stem oil consumption by relying on alternative fuel sources is overshadowed by China's and India's growing appetite for the plentiful commodity.

The U.S. Energy Information Administration reports that China and India are a leading cause for rising coal consumption and will continue that role for years as they emerge into developed countries. China also has shifted from being a major exporter of coal into a major importer as its demand outpaces its supply.

In the United States, demand eclipsed supply in 2007 as electricity generation and exports rose as production dipped. That trend is to continue this year as supply remains tight.

In a May presentation at the Merrill Lynch Global Metals & Mining Conference, Knoxville-headquartered National Coal Corp. reported that U.S. demand is exceeding supply because of:

• Mine closures and increased regulatory oversight;

• Increased electricity generation;

• A weak U.S. dollar that is contributing to rising exports and a leveling off of imports;

• Strong international demand for coal;

• Inventory drawdown that has run its course;

• Consolidation in the mining industry as reinvestment wanes. In 1980, the top 10 coal producers represented 33 percent of total coal production. In 2006, the top 10 accounted for 68 percent.

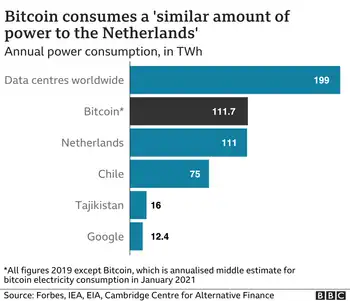

Another reason? More electricity needed to power more energy-guzzling personal computers, personal communication devices and big-screen, high-definition televisions spreading throughout American households.

Tim Patterson, secretary/treasurer of Smoky Mountain Coal Corp., a West Knoxville firm that brokers services like financing, transportation and logistics for coal mine operators, remembers starting in the coal business in 1978 when the mineral was selling for about $30 a ton.

Coal prices had reached a peak and the industry was buzzing with activity. Times were good for Central Appalachia's coal fields until a 19-year downward cycle began in 1981.

"Except for a few years when there was a threat of a labor strike, the market was pretty flat," Patterson said, noting that during those lean years mining companies had to invest in new technology to stay competitive.

"There has been a lot of consolidation," he said.

Coal mining's ups and downs are legendary, reliable trends that Daniel Roling has been able to set his calendar by.

The president and CEO of National Coal has been marking the cycles in 17-year increments, an interesting time frame given his estimate that it can take up to 17 years to develop a mine from property lease through permitting to daily production. Permits have taken as long as seven years to get, he noted.

But Roling has noticed a change in the cycle - they're getting longer.

"The present cycle is an upward cycle that could last 25 years. The last up cycle - 1974 to 1984 - built the last generation of coal mines in the U.S.," he said.

How does Roling explain the extended trend?

It's a confluence of factors led by the emergence of developing countries at a time when U.S. mining capacity has ebbed.

Domestic demand is overtaking supply as power generating needs grow at a 2 percent-a-year clip. TVA is raising rates by 20 percent on Oct. 1 as it faces higher prices for coal, natural gas and open-market electricity. The federal utility also is dusting off its nuclear power program, dealing with lower hydro-electric output because of drought conditions and is in the middle of a multibillion-dollar coal emission-reduction program to satisfy environmental concerns.

"We're at the point now where supply and demand are pretty much in balance. The reserve margin is the lowest since the 1950s. There's not a lot of surplus generating capacity," Roling said. "The coal industry did not earn its cost to capital in the 1980s and did not reinvest. So, production capacity peaked and even declined as did production."

That production lag may be a thing of the past. Coal permitting activity is up, but still not in line with prices, according to Tim Slone, a president of IRTEC, a mining engineering firm in Campbell County, one of Tennessee's few hot spots for coal mining.

Slone said existing mining companies are busier, but few new players are in the business.

SPatterson and Roling agree with Slone that investment now required to open a mine prices many would-be operators out of the market. Mining equipment and supplies are at a premium with world demand so high. Add to that the cost of mineral rights, leases, permitting, labor and production, and a venture quickly gets expensive.

Patterson provided a snapshot of the costs now associated with running a mine. He said a permit that cost $30,000 to $40,000 to secure about 10 years ago now costs at least $250,000 and in some cases closer to $1 million. A bulldozer, front-end loader or large rock truck can cost upward of $2 million each. And a high-wall miner used to extract coal from a seam that sold for $4.5 million three years ago now costs $7 million.

Smoky Mountain Coal could budget diesel fuel at $250,000 to $300,000 a month two years ago, but now that has risen to nearly $1 million per month. Explosives have doubled in price as have chemicals to process coal.

Where is the profit? As those costs have spiked, so has coal, which is selling for about $130 a ton, up from $40 to $50 five years ago.

"The reason prices are up is because costs are up, and environmentalists are making it almost impossible to mine coal," Patterson said.

Slone said it is easier to get mining permits in Kentucky and Virginia than in Tennessee, as evidenced by more mining activity in those states. That's a source of pride for environmental groups who have worked to tighten Tennessee's control over surface mining.

Cathie Bird, who chairs the strip mine issues committee for the group Save Our Cumberland Mountains, said SOCM has historically focused on surface, or strip, mining and doesn't have many issues with deep mining because they have had less adverse affects on Tennessee communities.

Particular concerns for SOCM and other groups like the Lindquist Environmental Appalachian Fellowship are mountaintop removal and cross-ridge mining, which involve removing the tops of mountains to access coal seams, flattening the peaks for post-mining land use.

The latest issue pitting environmental groups against the mining industry in Tennessee occurred last spring when legislation was debated to ban surface mining above 2,000 feet if a ridgeline is altered or disturbed. The bill also required a 100-foot buffer zone between a mining operation and a stream or other body of water.

The bill failed to pass after contentious hearings where the Lindquist group (LEAF) and the National Parks Conservation Association squared off against National Coal and the Tennessee Land and Mineral Resources Association.

The bill also exposed the difficulty in balancing rising power demand and economic development with the need to protect Tennessee's rich natural resources.

"A lot of our work has been to prevent Tennessee from getting that way - massive destruction of mountains and watersheds. Most of that is happening in Virginia and Kentucky," said Bird, who advocates for increased development of alternative energy sources to phase out coal as a fuel source.

"Our concern comes from communities and how much suffering those communities are exposed to if laws aren't followed," she said.

Knoxville lawyer Dawn Coppock, who is legislative director for LEAF, also has noticed an increase in coal mine permitting activity and is concerned that failure to have a law banning mountaintop removal and protection of watersheds will cost the state tourism dollars because scenic vistas will be scarred.

She stopped short of saying the scenic vistas protection bill will be reintroduced next year. She also believes environmental protections and mining can coexist.

"As long as we have strong environmental regulations, an increase in mining is not cause for alarm. We are not anti-coal. We are not anti-mining. We aren't even anti-surface mining. We just don't think you should blow the top off mountains," Coppock said.

To Roling, who worked for years as a coal industry analyst for Wall Street investment brokerage Merrill Lynch before becoming a coal mining company CEO, it's a matter of economics. When demand for coal dwindled, so did supply. That now has reversed and the industry is working to catch up.

Roling acknowledges that in the big picture National Coal Corp. is a tiny player, as is Tennessee. But he still sees opportunity for his company, for the state and the region to contribute to easing the area's energy ills.

"Demand for our coal internationally has increased dramatically - 80 million tons this year and projections of 100 million tons next year," he said. "The outlook for coal pricing is very healthy."

But he's concerned that the weight of environmental regulations is stifling investment, which could turn the United States into an importer of coal instead of an exporter.

"It's not a growing industry. Even though the U.S. has the biggest reserve base in the world, there's no incentive to invest," Roling said.

Given those deep reserves, Smoky Mountain Coal's Patterson believes the country must live with coal - it's too ingrained in the country's power supply - and it can help offset rapidly rising power costs.

"I'm for exploring new ways. When it makes sense, free enterprise will make green energy happen. But our country's economic well-being is based on cheap power and it will show up in our standard of living," Patterson said.

In the meantime, Smoky Mountain Coal will continue brokering deals for area coal operators and Roling will keep steering his company toward profitability.

Publicly traded National Coal sold its Kentucky operations earlier this year for $11 million to improve its finances and stimulate growth.

In the face of rising demand, the company is reopening idled mines in Tennessee and Alabama and is digging a new underground mine in the New River Basin north of Knoxville near the Kentucky border. The company has posted losses in recent quarters, but has seen its revenues rise as more coal is sold.

It has been negotiating contracts for future sales and renegotiating contracts to reflect the higher coal prices. The company's average selling price for coal in 2007 was $52.15 per ton, and in 2008 the average price is $62.25. In the second quarter, National Coal's revenue increased 67 percent to $31.6 million compared to $18.9 million in the same 2007 period. The amount of coal sold was up 23 percent to 4458,245 tons from 372,341 tons a year earlier.

Earnings are another matter. The company posted a net loss $9.9 million for the three-month period ended June 30, up from a net loss of $6.5 million a year earlier.

"The biggest obstacle to profitability has been the low selling price of coal and the rising cost of things like diesel fuel, blasting material, and steel. We use a lot of steel. Those costs have gone up quicker than the selling price," Roling said. "I believe the selling price will outpace the cost increases we've experienced as we sign new, higher-priced contracts."

Mining coal in East Tennessee and making money at it always will be a challenge. But it may be getting a bit easier - at least for a while.

"We're trying to make it profitable. Nobody is going to mine it for a loss. If prices stay this high we can all make a pretty good living. But I'm not sure that it will continue. My crystal ball doesn't go out that far," Patterson said.