Global CO2 emissions 'flatlined' in 2019, says IEA

High Voltage Maintenance Training Online

Our customized live online or in‑person group training can be delivered to your staff at your location.

- Live Online

- 12 hours Instructor-led

- Group Training Available

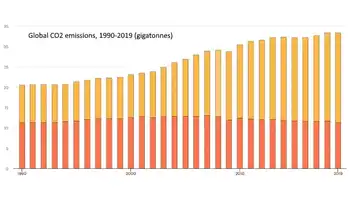

2019 Global CO2 Emissions stayed flat, IEA reports, as renewable energy growth, wind and solar deployment, nuclear output, and coal-to-gas switching in advanced economies offset increases elsewhere, supporting climate goals and clean energy transitions.

Key Points

33 gigatonnes, unchanged YoY, as advanced economies cut power emissions via renewables, gas, and nuclear.

✅ IEA reports emissions flat at 33 Gt despite 2.9% GDP growth

✅ Advanced economies cut power-sector CO2 via wind, solar, gas

✅ Nuclear restarts and mild weather aided reductions

Despite widespread expectations of another increase, global energy-related CO2 emissions stopped growing in 2019, according to International Energy Agency (IEA) data released today. After two years of growth, global emissions were unchanged at 33 gigatonnes in 2019, a notable marker in the global energy transition narrative even as the world economy expanded by 2.9%.

This was primarily due to declining emissions from electricity generation in advanced economies, thanks to the expanding role of renewable sources (mainly wind and solar across many markets), fuel switching from coal to natural gas, and higher nuclear power generation, the Paris-based organisation says in the report.

"We now need to work hard to make sure that 2019 is remembered as a definitive peak in global emissions, not just another pause in growth," said Fatih Birol, the IEA's executive director. "We have the energy technologies to do this, and we have to make use of them all."

Higher nuclear power generation in advanced economies, particularly in Japan and South Korea, avoided over 50 Mt of CO2 emissions. Other factors included milder weather in several countries, and slower economic growth in some emerging markets. In China, emissions rose but were tempered by slower economic growth and higher output from low-carbon sources of electricity. Renewables continued to expand in China, and 2019 was also the first full year of operation for seven large-scale nuclear reactors in the country.

A significant decrease in emissions in advanced economies in 2019 offset continued growth elsewhere. The USA recorded the largest emissions decline on a country basis, with a fall of 140 million tonnes, or 2.9%. US emissions are now down by almost 1 gigatonne from their peak in 2000. Emissions in the European Union fell by 160 million tonnes, or 5%, in 2019 driven by reductions in the power sector as electricity producers move away from coal in the generation mix. Japan’s emissions fell by 45 million tonnes, or around 4%, the fastest pace of decline since 2009, as output from recently restarted nuclear reactors increased.

Emissions in the rest of the world grew by close to 400 million tonnes in 2019, with almost 80% of the increase coming from countries in Asia where coal-fired power generation continued to rise, and in Australia emissions rose 2% due to electricity and transport. Coal-fired power generation in advanced economies declined by nearly 15%, reflecting a sharp fall in coal-fired electricity across multiple markets, as a result of growth in renewables, coal-to-gas switching, a rise in nuclear power and weaker electricity demand.

The IEA will publish a World Energy Outlook Special Report in June that will map out how to cut global energy-related carbon emissions by one-third by 2030 and put the world on track for longer-term climate goals, a pathway that, in Canada, will require more electricity to hit net-zero. It will also hold an IEA Clean Energy Transitions Summit in Paris on 9 July, bringing together key government ministers, CEOs, investors and other major stakeholders.

Birol will discuss the results published today tomorrow at an IEA Speaker Series event at its headquarters with energy and climate ministers from Poland, which hosted COP24 in Katowice; Spain, which hosted COP25 in Madrid; and the UK, which will host COP26 in Glasgow this year, as greenhouse gas concentrations continue to break records worldwide.