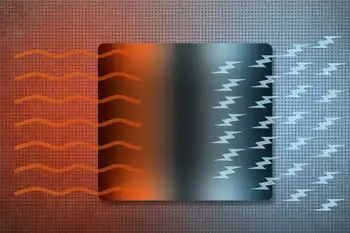

Turning thermal energy into electricity

Arc Flash Training CSA Z462 - Electrical Safety Essentials

Our customized live online or in‑person group training can be delivered to your staff at your location.

- Live Online

- 6 hours Instructor-led

- Group Training Available

Near-Field Thermophotovoltaics captures radiated energy across a nanoscale gap, using thin-film photovoltaic cells and indium gallium arsenide to boost power density and efficiency, enabling compact Army portable power from emitters via radiative heat transfer.

Key Points

A nanoscale TPV method capturing near-field photons for higher power density at lower emitter temperatures.

✅ Nanoscale gap boosts radiative transfer and usable photon flux

✅ Thin-film InGaAs cells recycle sub-band-gap photons via reflector

✅ Achieved ~5 kW/m2 power density with higher efficiency

With the addition of sensors and enhanced communication tools, providing lightweight, portable power has become even more challenging, with concepts such as power from falling snow illustrating how diverse new energy-harvesting approaches are. Army-funded research demonstrated a new approach to turning thermal energy into electricity that could provide compact and efficient power for Soldiers on future battlefields.

Hot objects radiate light in the form of photons into their surroundings. The emitted photons can be captured by a photovoltaic cell and converted to useful electric energy. This approach to energy conversion is called far-field thermophotovoltaics, or FF-TPVs, and has been under development for many years; however, it suffers from low power density and therefore requires high operating temperatures of the emitter.

The research, conducted at the University of Michigan and published in Nature Communications, demonstrates a new approach, where the separation between the emitter and the photovoltaic cell is reduced to the nanoscale, enabling much greater power output than what is possible with FF-TPVs for the same emitter temperature.

This approach, which enables capture of energy that is otherwise trapped in the near-field of the emitter is called near-field thermophotovoltaics or NF-TPV and uses custom-built photovoltaic cells and emitter designs ideal for near-field operating conditions, alongside emerging smart solar inverters that help manage conversion and delivery.

This technique exhibited a power density almost an order of magnitude higher than that for the best-reported near-field-TPV systems, while also operating at six-times higher efficiency, paving the way for future near-field-TPV applications, including remote microgrid deployments in extreme environments, according to Dr. Edgar Meyhofer, professor of mechanical engineering, University of Michigan.

"The Army uses large amounts of power during deployments and battlefield operations and must be carried by the Soldier or a weight constrained system," said Dr. Mike Waits, U.S. Army Combat Capabilities Development Command's Army Research Laboratory. "If successful, in the future near-field-TPVs could serve as more compact and higher efficiency power sources for Soldiers as these devices can function at lower operating temperatures than conventional TPVs."

The efficiency of a TPV device is characterized by how much of the total energy transfer between the emitter and the photovoltaic cell is used to excite the electron-hole pairs in the photovoltaic cell, where insights from near-light-speed conduction research help contextualize performance limits in semiconductors. While increasing the temperature of the emitter increases the number of photons above the band-gap of the cell, the number of sub band-gap photons that can heat up the photovoltaic cell need to be minimized.

"This was achieved by fabricating thin-film TPV cells with ultra-flat surfaces, and with a metal back reflector," said Dr. Stephen Forrest, professor of electrical and computer engineering, University of Michigan. "The photons above the band-gap of the cell are efficiently absorbed in the micron-thick semiconductor, while those below the band-gap are reflected back to the silicon emitter and recycled."

The team grew thin-film indium gallium arsenide photovoltaic cells on thick semiconductor substrates, and then peeled off the very thin semiconductor active region of the cell and transferred it to a silicon substrate, informing potential interfaces with home battery systems for distributed use.

All these innovations in device design and experimental approach resulted in a novel near-field TPV system that could complement distributed resources in virtual power plants for resilient operations.

"The team has achieved a record ~5 kW/m2 power output, which is an order of magnitude larger than systems previously reported in the literature," said Dr. Pramod Reddy, professor of mechanical engineering, University of Michigan.

Researchers also performed state-of-the-art theoretical calculations to estimate the performance of the photovoltaic cell at each temperature and gap size, informing hybrid designs with backup fuel cell solutions that extend battery life, and showed good agreement between the experiments and computational predictions.

"This current demonstration meets theoretical predictions of radiative heat transfer at the nanoscale, and directly shows the potential for developing future near-field TPV devices for Army applications in power and energy, communication and sensors," said Dr. Pani Varanasi, program manager, DEVCOM ARL that funded this work.