Rolls-Royce and Exelon UKSMR Partnership accelerates factory-built small modular reactors, nuclear power, clean energy, 440MW units, advanced manufacturing, fleet deployment, net zero goals, and resilient, low-cost baseload generation in the UK and globally.

Key Points

A partnership to deploy factory-built SMR stations, providing 440MW low-carbon baseload for the UK and export markets.

✅ 440MW factory-built SMR units with rapid modular assembly

✅ Exelon to operate and enhance high capacity factors

✅ Supports UK net zero, jobs, and export-led manufacturing

Rolls-Royce and Exelon Generation have signed a Memorandum of Understanding to pursue the potential for Exelon Generation to operate compact nuclear power stations both in the UK and internationally, including markets such as Canada where New Brunswick SMR questions are prompting public debate today.

Exelon Generation will be using their operational experience to assist Rolls Royce in the development and deployment of the UKSMR.

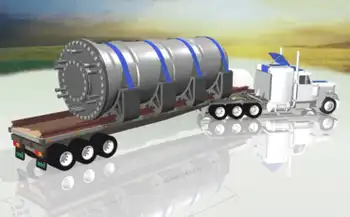

Rolls-Royce is leading a consortium that is designing a low-cost factory built nuclear power station, known as a small modular reactor (SMR), with UK mini-reactor approval anticipated as development progresses. Its standardised, factory-made components and advanced manufacturing processes push costs down, while the rapid assembly of the modules and components inside a weatherproof canopy on the power station site itself avoid costly schedule disruptions.

The consortium is working with its partners and UK Government to secure a commitment for a fleet of factory built nuclear power stations, each providing 440MW of electricity, to be operational within a decade, helping the UK meet its net zero obligations in line with the green industrial revolution policy set out by government. A fleet deployment in the UK will lead to the creation of new factories that will make the components and modules which will help the economy recover from the Covid-19 pandemic and pave the way for significant export opportunities as well.

The consortium members feature the best of nuclear engineering, construction and infrastructure expertise in Assystem, Atkins, BAM Nuttall, Jacobs, Laing O'Rourke, National Nuclear Laboratory, Nuclear Advanced Manufacturing Research Centre, Rolls-Royce and TWI. Exelon will add valuable operational experience to the team.

Tom Samson, interim Chief Executive Officer of the UKSMR consortium, said: 'Nuclear power is central to tackling climate change and economic recovery, but it must be affordable, reliable and investable and the way we manufacture and assemble our power station brings its cost down to be comparable with offshore wind.

'It's a compelling proposition that could draw new players into the UK's power generation landscape, improving choice for consumers and providing uninterrupted low carbon energy to homes and businesses.

'The opportunity to partner with Exelon is a very exciting prospect for our program, complementing our existing Consortium partnerships with one of the world's largest nuclear operator adds an important dimension to our growth ambitions, embodies the strength of the UK and USA alliance on nuclear matters and reflects wider international moves, such as a Canadian premiers' SMR initiative to accelerate technology development, and offers our future customers the ability to achieve the highest performance standards associated with Exelon's outstanding operational track record.'

The power stations will be built by the UKSMR consortium, before being handed over to be operated by power generation companies. Exelon Generation will work closely with the consortium during the pre-operation period. Exelon Nuclear operates 21 nuclear reactors in America, and U.S. regulators recently issued a final safety evaluation for a NuScale SMR that underscores momentum in the sector. The Exelon nuclear fleet is an integral part of the U.S. clean power mix; it produces more than 158 million megawatt-hours of clean electricity every year.

Bryan Hanson, EVP and COO of Exelon Generation said: 'We believe that SMRs are a crucial part of the world's clean energy mix, as projects like Darlington SMRs advance in Ontario. With our experience both in the US and internationally, Exelon is confident that we can help Rolls Royce ensure SMRs play a key role in the UK's energy future. We've had a very strong record of performance for 20 consecutive years, with a 2019 capacity factor of 95.7 percent. We will leverage this experience to achieve sustainably high capacity factors for the UKSMRs.'

Ralph Hunter, Managing Director of Exelon Nuclear Partners, who runs Exelon's international clean energy business, said: 'We have a strong track record of success to be the operator of choice for the UKSMR. We will help develop operational capability, training and human capacity development in the UK, as utilities such as Ontario Power Generation commit to SMRs abroad, ensuring localisation of skills and a strong culture of safety, performance and efficiency.'

By 2050 a full UK programme of a fleet of factory built nuclear power stations in the UK could create:

Up to 40,000 jobs GBP52BN of value to the UK economy GBP250BN of exports

The current phase of the programme has been jointly funded by all consortium members and UK Research and Innovation.

Related News