Duke Energy files cost update for power plant

By PennEnergy

Electrical Testing & Commissioning of Power Systems

Our customized live online or in‑person group training can be delivered to your staff at your location.

- Live Online

- 12 hours Instructor-led

- Group Training Available

The projects scale and complexity has added about $530 million to the previously approved $2.35 billion cost.

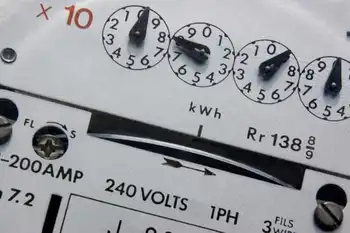

Indiana state utility regulators must review and approve Duke Energy Indianas filing before any new costs can be phased into customer electric rates.

Last November, Duke Energy Indiana alerted the commission that it was seeing upward pressure on costs as the projects engineering progressed. The company asked the IURC to schedule a proceeding to review a revised cost estimate.

The filing estimates the total cost of the Edwardsport IGCC project to be $2.88 billion, including projectfinancing costs. The total project, factoring in aspects such as engineering, construction and purchasing, is 57 percent complete. It is scheduled to be operating in 2012.

This is the first time a plant this size using this advanced clean coal technology has been built anywhere in the world, said James Turner, president and chief operating officer of Duke Energys Franchised Electric & Gas businesses. We worked with GE, Bechtel and other design firms to perform an engineering study early on however, as engineering progressed, the projects design and complexity expanded significantly. Unfortunately, this evolution in scope and complexity makes an increase in the cost estimate impossible to avoid, Turner added.

If approved, the increase in costs will add about 3 percent to the projects customer rate impact.

Based on a customers bill today, the project will result in an overall average 19 percent rate increase phased into rates by 2013.

Regulators granted the company permission in 2007 to construct the technologically advanced clean coal power plant in Edwardsport, Indiana. Regulators also approved the phase in of rate increases associated with the project.

The ability to phase in costs over time reduces the customer bill impact because it spreads out the increase and lowers financing costs. State utility regulators review and approve all plant costs before they are added to customer electric rates.

The 618MW plant will use advanced integrated gasification combined cycle technology. It will:

• Produce 10 times as much power as the existing plant at Edwardsport, yet with less environmental impact than the much smaller plant it replaces

• Be the first major new power plant built in Indiana in more than 20 years. The plant is key to modernizing the states aging electric system

• Generate marketable byproducts. This plant produces sulfur and slag for agricultural and construction materials

• Use less water. The IGCC plant will need less than onetenth the amount of water per day compared to the current plant when its operating.

The company will retire the existing 160MW plant — with coal and oil units more than 60 years old — in conjunction with the completion of the new facility.

About 1,400 construction workers and other professionals are working on site. That number is expected to grow to about 2,000 this summer. The plant will employ about 110120 fulltime workers. In addition, the 1.7 million to 1.9 million tons of coal the plant will use each year will support an estimated 170 mining jobs.

The IGCC plant will use technology to gasify coal, strip out pollutants, and then burn that cleaner gas to produce electricity. The plants efficiency reduces the plants carbon emissions per megawatthour by nearly half.

Duke Energy Indianas operations provide about 6,800 MW of electricity capacity to approximately 780,000 customers, making it the states largest electric supplier.