Hybrids replace “big dirty trucks”

By Times Transcript

Substation Relay Protection Training

Our customized live online or in‑person group training can be delivered to your staff at your location.

- Live Online

- 12 hours Instructor-led

- Group Training Available

"The era of the big dirty truck is gone," Peter Nelson, executive-director of the Atlantic Provinces Trucking Association said while admiring a shiny new Peterbilt Model 335 Hybrid on display at the company's showroom in the Caledonia Industrial Park. "We've seen some real changes. These trucks are burning 90 per cent cleaner than they were 18 months or two years ago."

He says the new breed of trucks will help customers save money, burn less fuel and be more environmentally friendly.

The new Peterbilt Hybrid, which is built at the company's plant in Quebec and is painted green for a reason, was recently brought to Moncton to stir up interest in the new line of environmentally-friendly work trucks. Peterbilt is a well-known truck manufacturer that has its headquarters in Texas. It operates a manufacturing facility in Ste-Therese, Quebec.

The Model 335 on display is set up with a 60-foot boom and bucket which makes it ideal for utilities, power companies, municipalities and sign companies for working on overhead lines, wires, signs, tree-trimming or other tasks. Available in a Class 7 configuration, the Model 335 can be set up as boom truck, fire & rescue vehicle, delivery truck with refrigerated compartment, municipal maintenance truck and even as a garbage collection truck.

Matt Preston, a district sales manager for Peterbilt of Canada, said the hybrid technology matches a 260-horsepower diesel engine with an electric power supply powered by two large lithium-ion batteries, giving it a total of 320 horsepower. He said the hybrid system can result in a 30 per cent increase in fuel economy and an 80 per cent reduction in idle times.

A normal truck of this size could cost in the area of $300,000 depending on how it is set up, and the hybrid would likely cost about $50,000 more, but Preston says the amount of fuel saved would pay for itself quickly.

He explained that conventional trucks need to have their diesel engine running constantly to provide power to the Power Take-Off or PTO. In a conventional truck, the PTO is the power required to operate a hydraulic boom, refrigeration unit, compressor, compactor or other piece of machinery attached to the vehicle. But in the hybrid, the PTO is powered by the batteries which means the diesel engine can be shut off. For example, if the truck was operated by a utility like NB Power the truck could be moved into position and the engine shut down while the crew is working in the boom bucket. The PTO can run for about 28 minutes on battery power and the diesel engine will start automatically and run for about four and a half minutes to recharge the batteries.

Preston said conventional work trucks often run all day so the hybrid can make a big difference in fuel savings and reduced carbon dioxide emissions.

The two rechargeable lithium-ion batteries are basically supersized versions of the batteries in a regular cellphone, except they are about twice the size of a regular car battery, weigh about 55 pounds each and provide 340 volts of electricity. The black box that houses the batteries has its own cooler and air filtration system. A control panel and screen inside the truck allows the driver to keep a constant watch on how the system is operating.

The electric-powered drive system can also power the entire vehicle for short distances, meaning it can run virtually silent. While driving, the diesel and electric systems works together to provide power to the wheels. The quiet nature of the vehicles would be a benefit when working in residential neighbourhoods during late-night hours. The electric drive system also acts as a braking system, which saves wear and tear on the disc brakes fitted on the vehicle.

The technology being used in diesel-electric trucks isn't all that new. Similar systems have been used in diesel locomotives for many years. But improvements to the technology have allowed the hybrid system to move into conventional passenger vehicles and now work trucks. The technology is also spreading to bigger trucks and the tractor-trailers that rule the highways.

Preston said companies like Purolator, Coca-Cola and Wal-Mart are starting to embrace hybrid technology in their fleets of delivery vehicles, especially in urban environments where the trucks are in constant stop-and-go traffic.

"For local delivery, they will make a huge difference."

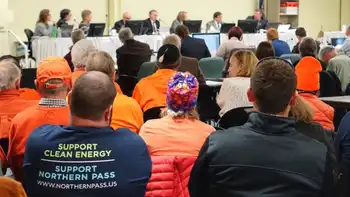

He said the demo model will remain at the Peterbilt showroom to generate interest among potential customers in Atlantic Canada. The truck drew interest yesterday from representatives from municipalities, utilities and private companies. Among those interested were Riverview Deputy Fire Chief Milt Cawley and Riverview councillor Sherry Wilson, who said the idea of saving money on fuel while being environmentally responsible is very appealing.

Peterbilt and other truck manufacturers have other models of "green" trucks for delivery, work and highway transport use.