Hydroelectricity Under Pumped Storage Capacity

Substation Relay Protection Training

Our customized live online or in‑person group training can be delivered to your staff at your location.

- Live Online

- 12 hours Instructor-led

- Group Training Available

Pumped Storage Hydroelectricity balances renewable energy, stabilizes the grid, and provides large-scale energy storage using reservoirs and reversible turbines, delivering flexible peak power, frequency control, and rapid response to variable wind and solar generation.

Key Points

A reversible hydro system that stores energy by pumping water uphill, then generates flexible peak power.

✅ Balances variable wind and solar with rapid ramping

✅ Stores off-peak electricity in upper reservoirs

✅ Enhances grid stability, frequency control, and reserves

The expense of hydroelectricity is moderately low, making it a serious wellspring of sustainable power. The hydro station burns-through no water, dissimilar to coal or gas plants. The commonplace expense of power from a hydro station bigger than 10 megawatts is 3 to 5 US pennies for every kilowatt hour, and Niagara Falls powerhouse upgrade projects show how modernization can further improve efficiency and reliability. With a dam and supply it is likewise an adaptable wellspring of power, since the sum delivered by the station can be shifted up or down quickly (as meager as a couple of moments) to adjust to changing energy requests.

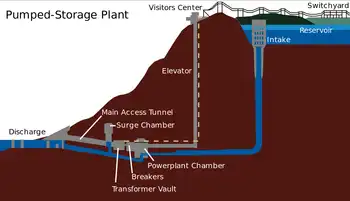

When a hydroelectric complex is developed, the task creates no immediate waste, and it for the most part has an extensively lower yield level of ozone harming substances than photovoltaic force plants and positively petroleum product fueled energy plants, with calls to invest in hydropower highlighting these benefits. In open-circle frameworks, unadulterated pumped storage plants store water in an upper repository with no normal inflows, while pump back plants use a blend of pumped storage and regular hydroelectric plants with an upper supply that is renewed to a limited extent by common inflows from a stream or waterway.

Plants that don't utilize pumped capacity are alluded to as ordinary hydroelectric plants, and initiatives focused on repowering existing dams continue to expand clean generation; regular hydroelectric plants that have critical capacity limit might have the option to assume a comparable function in the electrical lattice as pumped capacity by conceding yield until required.

The main use for pumped capacity has customarily been to adjust baseload powerplants, however may likewise be utilized to decrease the fluctuating yield of discontinuous fuel sources, while emerging gravity energy storage concepts broaden long-duration options. Pumped capacity gives a heap now and again of high power yield and low power interest, empowering extra framework top limit.

In specific wards, power costs might be near zero or once in a while negative on events that there is more electrical age accessible than there is load accessible to retain it; despite the fact that at present this is infrequently because of wind or sunlight based force alone, expanded breeze and sun oriented age will improve the probability of such events.

All things considered, pumped capacity will turn out to be particularly significant as an equilibrium for exceptionally huge scope photovoltaic age. Increased long-distance bandwidth, including hydropower imports from Canada, joined with huge measures of energy stockpiling will be a critical piece of directing any enormous scope sending of irregular inexhaustible force sources. The high non-firm inexhaustible power entrance in certain districts supplies 40% of yearly yield, however 60% might be reached before extra capaciy is fundamental.

Pumped capacity plants can work with seawater, despite the fact that there are extra difficulties contrasted with utilizing new water. Initiated in 1966, the 240 MW Rance flowing force station in France can incompletely function as a pumped storage station. At the point when elevated tides happen at off-top hours, the turbines can be utilized to pump more seawater into the repository than the elevated tide would have normally gotten. It is the main enormous scope power plant of its sort.

Alongside energy mechanism, pumped capacity frameworks help control electrical organization recurrence and give save age. Warm plants are substantially less ready to react to abrupt changes in electrical interest, and can see higher thermal PLF during periods of reduced hydro generation, conceivably causing recurrence and voltage precariousness.

Pumped storage plants, as other hydroelectric plants, including new BC generating stations, can react to stack changes in practically no time. Pumped capacity hydroelectricity permits energy from discontinuous sources, (for example, sunlight based, wind) and different renewables, or abundance power from consistent base-load sources, (for example, coal or atomic) to be put something aside for times of more popularity.

The repositories utilized with siphoned capacity are tiny when contrasted with ordinary hydroelectric dams of comparable force limit, and creating periods are regularly not exactly a large portion of a day. This technique produces power to gracefully high top requests by moving water between repositories at various heights.

Now and again of low electrical interest, the abundance age limit is utilized to pump water into the higher store. At the point when the interest gets more noteworthy, water is delivered once more into the lower repository through a turbine. Pumped capacity plans at present give the most monetarily significant methods for enormous scope matrix energy stockpiling and improve the every day limit factor of the age framework. Pumped capacity isn't a fuel source, and shows up as a negative number in postings.