MARVEL microreactor debuts at Idaho National Laboratory as a 100 kW, liquid-metal-cooled, zero-emissions generator powering a nuclear microgrid, integrating wind and solar for firm, clean energy in advanced nuclear applications research.

Key Points

A 100 kW, liquid-metal-cooled INL reactor powering a nuclear microgrid and showcasing zero-emissions clean energy.

✅ 100 kW liquid-metal-cooled microreactor at INL

✅ Powers first nuclear microgrid for applications testing

✅ Integrates with wind and solar for firm clean power

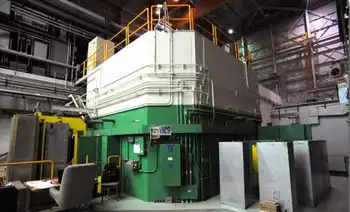

Inside the Transient Reactor Test Facility, a towering, windowless gray block surrounded by barbed wire, researchers are about to embark on a mission to solve one of humanity’s greatest problems with a tiny device.

Next year, they will begin construction on the MARVEL reactor. MARVEL stands for Microreactor Applications Research Validation and EvaLuation. It’s a first-of-a-kind nuclear power generator with a mini-reactor design that is cooled with liquid metal and produces 100 kilowatts of energy. By 2024, researchers expect MARVEL to be the zero-emissions engine of the world’s first nuclear microgrid at Idaho National Laboratory (INL).

“Micro” and “tiny,” of course, are relative. MARVEL stands 15 feet tall, weighs 2,000 pounds, and can fit in a semi-truck trailer. But it's minuscule compared to conventional nuclear power plants, which span acres, produces gigawatts of electricity to power whole states, and can take more than a decade to build.

For INL, where scientists have tested dozens of reactors over the decades across an area three-quarters the size of Rhode Island, it’s a radical reimagining of the technology. This advanced reactor design could help overcome the biggest obstacles to nuclear energy: safety, efficiency, scale, cost, and competition. MARVEL is an experiment to see how all these pieces could fit together in the real world.

“It’s an applications test reactor where we’re going to try to figure out how we extract heat and energy from a nuclear reactor and apply it — and combine it with wind, solar, and other energy sources,” said Yasir Arafat, head of the MARVEL program.

The project, however, comes at a time when nuclear power is getting pulled in wildly different directions, from phase-outs to new strategies like the UK’s green industrial revolution that shapes upcoming reactors.

Germany just shut down its last nuclear reactors. The U.S. just started up its first new reactor in 30 years, underscoring a shift. France, the country with the largest share of nuclear energy on its grid, saw its atomic power output decline to its lowest since 1988 last year. Around the world, there are currently 60 nuclear reactors under construction, with 22 in China alone.

But the world is hungrier than ever for energy. Overall electricity demand is growing: Global electricity needs will increase nearly 70 percent by 2050 compared to today’s consumption, according to the Energy Information Administration. At the same time, the constraints are getting tighter. Most countries worldwide, including the U.S., have committed to net-zero goals by the middle of the century, even as demand rises.

To meet this energy demand without worsening climate change, the U.S. Energy Department’s report on advanced nuclear energy released in March said, “the U.S. will need ~550–770 [gigawatts] of additional clean, firm capacity to reach net-zero; nuclear power is one of the few proven options that could deliver this at scale.”

The U.S. government is now renewing its bets on nuclear power to produce steady electricity without emitting greenhouse gases. The Bipartisan Infrastructure Law included $6 billion to keep existing nuclear power plants running. In addition, the Inflation Reduction Act, the U.S. government’s largest investment in countering climate change, includes several provisions to benefit atomic power, including tax credits for zero-emissions energy.

“It’s a game changer,” said John Wagner, director of INL.

The tech sector is jumping in, too, as atomic energy heats up across startups and investors. In 2021, venture capital firms poured $3.4 billion into nuclear energy startups. They’re also pouring money into even more far-out ideas, like nuclear fusion power. Public opinion has also started moving. An April Gallup poll found that 55 percent of Americans favour and 44 percent oppose using atomic energy, the highest levels of support in 10 years.

Related News