City of Vancouver named Clean Energy Champion for Bloedel upgrades

Protective Relay Training - Basic

Our customized live online or in‑person group training can be delivered to your staff at your location.

- Live Online

- 12 hours Instructor-led

- Group Training Available

BC Hydro Clean Energy Champions highlights Vancouver's Bloedel Conservatory electrification with a massive heat pump, clean electricity, LED lighting, deep energy efficiency, and 90% greenhouse gas reductions advancing climate action across buildings and industry.

Key Points

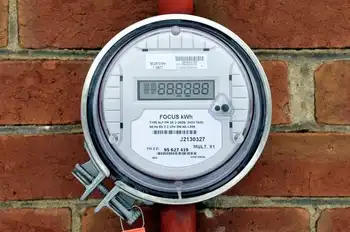

A BC Hydro program honoring clean electricity adoption in homes, transport, and industry to replace fossil fuels.

✅ Vancouver's Bloedel Conservatory cut GHGs by 90% with a heat pump

✅ LEDs and electrification boost efficiency, comfort, and reliability

✅ Nominations open for residents, businesses, and Indigenous groups

The City of Vancouver has been selected as BC Hydro’s first Clean Energy Champion for energy efficient upgrades made at the Bloedel Conservatory that cut greenhouse gas emissions by 90 per cent, a meaningful step given concerns about 2050 greenhouse gas targets in B.C.

BC Hydro’s Clean Energy Champions program is officially being launched today to recognize residents, businesses, municipalities, Indigenous and community groups across B.C. that have made the choice to switch from using fossil fuels to using clean electricity in three primary areas: homes and buildings, transportation, and industry, even as drought challenges power generation in B.C. The City of Vancouver is being recognized as the first champion for demonstrating its commitment to using clean energy, including power from projects like Site C's electricity, to fight climate change at its landmark Bloedel Conservatory.

Earlier this year, the City of Vancouver installed a large air source heat pump at Bloedel Conservatory – more than 50 times the size of a heat pump used in a typical B.C. home – that uses electricity instead of natural gas to heat and cool the dome's interior, which is home to more than 500 exotic plants and flowers, and 100 exotic birds, aligning with citywide debates such as Vancouver’s reversal on gas appliances policy. It is the biggest heat pump the City of Vancouver has ever installed, with 210 tonnes of cooling capacity.

A heat pump that provides cooling in the summer and heating in the winter, helping reduce reliance on wasteful air conditioning that can drive up energy bills, is ideal for the conservatory, as its dome is completely made of glass, which can be challenging for temperature regulation. While the dome experiences a lot of heat loss in the colder months, its need for cooling in warmer weather is even greater to ensure the safety of the wildlife and plants that call it home.

The clean energy upgrades do not end there though. All lighting in the building has been upgraded to energy-efficient LEDs, reflecting conservation themes highlighted by 2018 Earth Hour electricity use discussions, and outside colour-changing LEDs now surround the perimeter and light up the dome at night.

BC Hydro is calling for nominations from B.C. residents, businesses, municipalities or Indigenous and community groups that have taken steps to lower their carbon footprint and adopt new clean energy technologies, and continues to support customers through programs like its winter payment plan during colder months. If you or someone you know is a Clean Energy Champion, nominate them at bchydro.com/cleanenergychampions.