California Biofuels vs EV Subsidies examines tradeoffs in decarbonization, greenhouse gas reductions, clean energy deployment, charging infrastructure, energy security, lifecycle emissions, and transportation sector policy to meet climate goals and accelerate sustainable mobility.

Key Points

Policy tradeoffs weighing biofuels and EVs to cut GHGs, boost energy security, and advance clean transportation.

✅ Near-term blending cuts emissions from existing fleets

✅ EVs scale with a cleaner grid and charging buildout

✅ Lifecycle impacts and costs guide optimal subsidy mix

California is at the forefront of the transition to a greener economy, driven by its ambitious goals to reduce greenhouse gas emissions and combat climate change. As part of its strategy, the state is grappling with the question of whether it should subsidize out-of-state biofuels or in-state electric vehicles (EVs) to meet these goals. Both options come with their own sets of benefits and challenges, and the decision carries significant implications for the state’s environmental, economic, and energy landscapes.

The Case for Biofuels

Biofuels have long been promoted as a cleaner alternative to traditional fossil fuels like gasoline and diesel. They are made from organic materials such as agricultural crops, algae, and waste, which means they can potentially reduce carbon emissions in comparison to petroleum-based fuels. In the context of California, biofuels—particularly ethanol and biodiesel—are viewed as a way to decarbonize the transportation sector, which is one of the state’s largest sources of greenhouse gas emissions.

Subsidizing out-of-state biofuels can help California reduce its reliance on imported oil while promoting the development of biofuel industries in other states. This approach may have immediate benefits, as biofuels are widely available and can be blended with conventional fuels to lower carbon emissions right away. It also allows the state to diversify its energy sources, improving energy security by reducing dependency on oil imports.

Moreover, biofuels can be produced in many regions across the United States, including rural areas. By subsidizing out-of-state biofuels, California could foster economic development in these regions, creating jobs and stimulating agricultural innovation. This approach could also support farmers who grow the feedstock for biofuel production, boosting the agricultural economy in the U.S.

However, there are drawbacks. The environmental benefits of biofuels are often debated. Critics argue that the production of biofuels—particularly those made from food crops like corn—can contribute to deforestation, water pollution, and increased food prices. Additionally, biofuels are not a silver bullet in the fight against climate change, as their production and combustion still release greenhouse gases. When considering whether to subsidize biofuels, California must also account for the full lifecycle emissions associated with their production and use.

The Case for Electric Vehicles

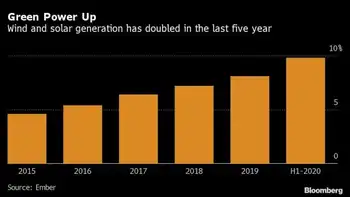

In contrast to biofuels, electric vehicles (EVs) offer a more direct pathway to reducing emissions from transportation. EVs are powered by electricity, and when coupled with renewable energy sources like solar or wind power, they can provide a nearly zero-emission solution for personal and commercial transportation. California has already invested heavily in EV infrastructure, including expanding its network of charging stations and exploring how EVs can support grid stability through vehicle-to-grid approaches, and offering incentives for consumers to purchase EVs.

Subsidizing in-state EVs could stimulate job creation and innovation within California's thriving clean-tech industry, with other states such as New Mexico projecting substantial economic gains from transportation electrification, and the state has already become a hub for electric vehicle manufacturers, including Tesla, Rivian, and several battery manufacturers. Supporting the EV industry could further strengthen California’s position as a global leader in green technology, attracting investment and fostering growth in related sectors such as battery manufacturing, renewable energy, and smart grid technology.

Additionally, the environmental benefits of EVs are substantial. As the electric grid becomes cleaner with an increasing share of renewable energy, EVs will become even greener, with lower lifecycle emissions than biofuels. By prioritizing EVs, California could further reduce its carbon footprint while also achieving its long-term climate goals, including reaching carbon neutrality by 2045.

However, there are challenges. EV adoption in California remains a significant undertaking, requiring major investments in infrastructure as they challenge state power grids in the near term, technology, and consumer incentives. The cost of EVs, although decreasing, still remains a barrier for many consumers. Additionally, there are concerns about the environmental impact of lithium mining, which is essential for EV batteries. While renewable energy is expanding, California’s grid is still reliant on fossil fuels to some degree, and in other jurisdictions such as Canada's 2019 electricity mix fossil generation remains significant, meaning that the full emissions benefit of EVs is not realized until the grid is entirely powered by clean energy.

A Balancing Act

The debate between subsidizing out-of-state biofuels and in-state electric vehicles is ultimately a question of how best to allocate California’s resources to meet its climate and economic goals. Biofuels may offer a quicker fix for reducing emissions from existing vehicles, but their long-term benefits are more limited compared to the transformative potential of electric vehicles, even as some analysts warn of policy pitfalls that could complicate the transition.

However, biofuels still have a role to play in decarbonizing hard-to-abate sectors like aviation and heavy-duty transportation, where electrification may not be as feasible in the near future. Thus, a mixed strategy that includes both subsidies for EVs and biofuels may be the most effective approach.

Ultimately, California’s decision will likely depend on a combination of factors, including technological advancements, 2021 electricity lessons, and the pace of renewable energy deployment, and the state’s ability to balance short-term needs with long-term environmental goals. The road ahead is not easy, but California's leadership in clean energy will be crucial in shaping the nation’s response to climate change.

Related News