Latest Dielectric Fluids Articles

Dielectric Fluid

Dielectric fluid is an insulating liquid used in electrical equipment like transformers and capacitors to prevent arcing, dissipate heat, and ensure system reliability. It offers high dielectric strength, thermal stability, and moisture resistance for safe operation.

What is Dielectric Fluid?

Dielectric fluid is a critical component in the operation and safety of electrical equipment, especially transformers and high-voltage switchgear.

✅ Provides electrical insulation and prevents arcing in high-voltage systems.

✅ Offers excellent thermal conductivity to dissipate heat.

✅ Protects components from moisture and contamination.

For industrial electricians, understanding their role in insulation, cooling, and arc suppression is essential for ensuring system reliability and preventing electrical failures. Let's review the properties, types, and maintenance requirements of dielectric fluids, providing practical insights into how they support energy efficiency, equipment longevity, and fire safety. Readers will learn about testing procedures, contamination risks, and how proper fluid management can minimize downtime and enhance overall electrical system performance. An oil-filled transformer relies on dielectric fluid to provide both insulation and cooling, ensuring safe and efficient operation.

Electrical Transformer Maintenance Training

Substation Maintenance Training

Request a Free Training Quotation

Applications in Electrical Equipment

In the realm of electrical equipment, insulating fluids are indispensable. They serve as both insulating and cooling agents, safeguarding systems from electric discharges while effectively dissipating heat. High-voltage applications, such as transformers, capacitors, and cables, rely heavily on these fluids to maintain stability and reliability. By preventing electric breakdown in these critical components, dielectric fluid ensures the longevity and efficiency of power distribution networks, which are the backbone of modern energy systems. The quality of transformer oil is crucial because its dielectric properties directly affect breakdown voltage and reliability.

Role in Immersion Cooling

The role of dielectric fluid in immersion cooling has gained prominence with the rise of data-intensive industries. Immersion cooling involves submerging electronic components in a thermally stable dielectric liquid to enhance heat transfer and reduce energy consumption. This technique is particularly advantageous in data centers, where efficient cooling solutions are essential. By dissipating heat more effectively than traditional air-cooling methods, dielectric fluid enables high-performance computing systems to operate at optimal levels while minimizing their environmental impacts. Understanding the role of transformer core and its interaction with insulating fluids can optimize cooling and extend transformer lifespan.

Comparison with Mineral Oils

A frequent comparison in the industry is between dielectric fluid and traditional mineral oil. While both serve as insulators and coolants, advanced dielectric fluid surpasses mineral oils in terms of thermal stability, oxidation resistance, and eco-friendliness. In high-voltage applications, \fluids offer lower operating temperatures and improved system reliability, reducing failure rates and extending service life. These properties make them an ideal choice for industries seeking to strike a balance between performance and sustainability.

Comparison of Dielectric Fluids

| Fluid Type | Key Properties | Advantages | Limitations |

|---|---|---|---|

| Mineral Oil | Moderate dielectric strength, good cooling, low cost | Widely available, proven track record | Low fire point, poor biodegradability |

| Natural Ester | High dielectric strength, high fire point (>300°C) | Biodegradable, excellent moisture tolerance | Higher cost, potential oxidation if unmanaged |

| Synthetic Ester | High thermal stability, excellent oxidation resistance | Long service life, superior high-temperature performance | Expensive, less eco-friendly than natural esters |

| Nanofluids | Enhanced dielectric strength and heat transfer via nanoparticles | Improved cooling, reduced aging, and emerging technology | Still experimental, higher production cost |

Types of Dielectric Fluids – Mineral Oil, Natural Ester, Synthetic Ester, Emerging Nanofluids

Dielectric fluid is categorized into several types, each with distinct properties and applications. Mineral oil has been the traditional choice due to its low cost and reliable insulation; however, it has limitations, including low flash points and environmental concerns. Natural ester fluids, derived from vegetable oils, offer high biodegradability, excellent moisture absorption, and fire safety advantages with fire points exceeding 300°C. Synthetic esters provide superior oxidation stability and thermal performance, making them suitable for high-load and high-temperature applications. Emerging nanofluids, enhanced with nanoparticles such as graphene or titanium dioxide, are at the forefront of innovation, offering improved thermal conductivity, higher dielectric strength, and enhanced aging resistance compared to conventional fluids. Regular testing of transformer oil filling is essential to avoid contamination and maintain high dielectric strength.

Material Compatibility & Impregnation – Testing Standards, Handling Guidance, Temperature Considerations

The interaction of dielectric fluids with insulation materials, gaskets, and seals plays a vital role in system performance. Certain fluids can cause swelling, shrinkage, or chemical degradation of elastomer-based gaskets, leading to leaks or compromised insulation. Modern ester fluids often require gasket materials that are highly resistant to hydrolysis and oxidation, such as nitrile or fluorocarbon elastomers, which offer superior stability compared to standard rubber seals.

Solid dielectrics, like pressboard or paper insulation, are directly affected by fluid absorption and impregnation. A properly selected fluid not only insulates but also strengthens these materials by filling microscopic voids and preventing moisture ingress. Poor fluid-material compatibility can reduce dielectric strength and lead to premature equipment failure.

The impregnation process, often carried out using vacuum-pressure cycles, ensures that the fluid thoroughly saturates the cellulose insulation. Vacuum impregnation removes trapped air and moisture before fluid introduction, improving dielectric performance and reducing the risk of partial discharges. Heating the fluid slightly during impregnation enhances its flow properties and ensures deep penetration. Standards like ASTM D3455 are used to verify material compatibility, while strict handling guidelines prevent contamination and degradation during storage. Proper transformer insulation depends on the fluid’s ability to prevent arcing and maintain thermal stability under load.

Material Compatibility and Impregnation Guidelines

| Aspect | Key Details | Recommended Standards/Tests | Notes and Best Practices |

|---|---|---|---|

| Gasket Compatibility | Evaluates swelling, shrinkage, and chemical stability of elastomers | ASTM D3455 (Compatibility Testing) | Use nitrile or fluorocarbon gaskets for ester-based fluids |

| Solid Dielectrics | Interaction with pressboard, paper, or cellulose insulation | IEC 60296 (Insulating Liquids) | Ensure low-moisture fluids to prevent insulation breakdown |

| Impregnation Process | Saturation of solid insulation with dielectric fluid | Vacuum-Pressure Impregnation Methods | Perform multi-cycle vacuum drying for optimal saturation |

| Handling Guidance | Preventing contamination during storage and transfer | ASTM D923 (Sampling Insulating Liquids) | Use sealed containers and moisture-proof handling systems |

| Temperature Control | Managing viscosity and flow during impregnation | ASTM D3487 (Transformer Oils) | Preheat fluid slightly (40–60°C) for better impregnation |

Influence on Gaskets and Dielectric Materials

The compatibility of insulating fluids with gaskets, seals, and solid dielectric materials is critical for the long-term reliability of electrical equipment. Certain fluids can cause swelling, shrinkage, or chemical degradation of elastomer-based gaskets, leading to leaks or compromised insulation. Modern natural and synthetic ester fluids often require gasket materials that are highly resistant to hydrolysis and oxidation, such as nitrile or fluorocarbon elastomers, which offer superior stability compared to standard rubber seals.

Solid dielectrics, like pressboard or paper insulation, are directly affected by fluid absorption and impregnation. A properly selected fluid not only insulates but also strengthens these materials by filling microscopic voids and preventing moisture ingress. Poor fluid-material compatibility can reduce dielectric strength and lead to premature equipment failure.

Performance Metrics & Diagnostics – Presenting Typical Values, Standards, and Testing Procedures

Key performance metrics for insulating fluids include dielectric breakdown voltage, moisture content, viscosity, thermal conductivity, and flash point. Testing standards such as IEC 60156 (breakdown voltage), ASTM D877/D1816 (oil testing), and IEC 60247 (dielectric dissipation factor) are widely used to evaluate fluid health. Dissolved Gas Analysis (DGA) is another critical tool that monitors the condition of transformer oils by detecting gases produced during thermal or electrical faults.

Regular diagnostic testing allows early detection of contamination, oxidation, or moisture ingress. By tracking these values, maintenance teams can take corrective action before failures occur, extending equipment life and ensuring uninterrupted service.

Innovations – Nanofluids and Sustainability Trends

The development of nanofluids is revolutionizing dielectric technology. By suspending nanoparticles like Al₂O₃, SiO₂, or graphene in base fluids, engineers have achieved significant improvements in dielectric strength, heat transfer, and thermal stability. These advanced fluids operate under higher electrical stress while maintaining lower temperatures, leading to greater reliability and efficiency.

Sustainability trends favor the use of natural and synthetic esters due to their biodegradability, reduced greenhouse gas footprint, and compliance with modern fire safety and environmental standards. As industries shift toward eco-friendly energy solutions, insulating fluids are being optimized to deliver both performance and environmental benefits. Monitoring breakdown voltage helps evaluate the condition of dielectric fluids and ensures they can withstand high voltages.

Practical Guidance – Selection Criteria Based on Fire Safety, Environmental Regulations, Maintenance Strategy, and Transformer Design Optimization

Choosing the right fluid involves striking a balance between technical performance and safety and environmental requirements. Fire safety considerations often favour natural esters, which have much higher fire points than mineral oils. Environmental regulations are increasingly encouraging fluids with low toxicity and high biodegradability to minimize ecological risks. A maintenance strategy also plays a role; fluids with greater oxidation stability and moisture tolerance can extend maintenance intervals, thereby lowering overall operating costs. Ultimately, transformer design optimization—including heat transfer requirements, viscosity, and load profiles—may dictate which fluid type offers the best efficiency and long-term reliability. Core parts of transformer components are submerged in dielectric fluid to minimize electrical discharge and control temperature.

Frequently Asked Questions

What are the Critical Components for Industrial Electricians?

Understanding the intricacies of electrical power distribution transformers is paramount for industrial electricians. These vital components play a pivotal role in the efficient and reliable delivery of electrical power to industries and businesses worldwide. By delving into the fundamental concepts of transformer operation, types, maintenance, and future trends, industrial electricians can gain valuable insights to optimize electrical systems, troubleshoot potential issues, and ensure a reliable and uninterrupted power supply. Insulating oil is essential for preventing electric discharges in high-voltage equipment. By immersing electrical components in these fluids, manufacturers can significantly reduce the risk of arcing and short circuits. Techniques like immersion cooling utilize insulating oil to effectively dissipate heat generated by high-power components, ensuring optimal performance and longevity.

What are the key characteristics of an effective electrical insulating oil?

The primary function of electrical insulating oil is to provide electrical insulation. Filling the gaps between electrical components prevents arcing and short circuits, which can lead to equipment failure and potentially hazardous situations. Additionally, dielectric fluid excels at dissipating heat generated by electrical equipment, ensuring optimal performance and longevity.

What are the most common types of electrical insulating oil, and where are they used?

Electrical insulating oil comes in various types, each with its unique properties and applications. Historically, mineral oil has been the most commonly used dielectric fluid, offering a balance of cost-effectiveness and reliability. However, its environmental impact and susceptibility to degradation have led to the development of alternative options. Synthetic esters, for instance, provide superior dielectric properties, thermal stability, and biodegradability, making them a more environmentally friendly choice. Silicone fluids, renowned for their exceptional thermal stability and resistance to oxidation, are frequently employed in high-voltage applications where reliability and long-term performance are crucial. While perfluorinated fluids offer exceptional dielectric strength and thermal stability, their high cost and potential environmental impact limit their widespread use.

The performance of electrical insulating oil is influenced by several factors. A crucial factor is dielectric strength, which measures the fluid's ability to withstand high voltages without breaking down. Additionally, the fluid's thermal stability is essential for maintaining its insulating properties under varying temperature conditions. Chemical stability is also important, as it ensures the fluid's resistance to degradation and oxidation. Furthermore, a low flash point and flammability rating are crucial for safety, especially in enclosed environments. Lastly, the environmental impact of the fluid, including its biodegradability and toxicity, is becoming increasingly significant in the selection of dielectric fluids.

How does transformer oil impact sustainability?

Regular testing and maintenance are crucial to ensure the optimal performance of insulating oil. These tests evaluate critical properties, including dielectric strength, moisture content, and acidity level. By monitoring these parameters, engineers can identify potential issues and take corrective actions to prevent equipment failures. This proactive approach helps maintain the reliability and safety of electrical systems.

Dielectric fluid is an essential component in high-voltage electrical systems. They provide critical insulation and cooling properties, preventing electrical breakdowns and ensuring the reliable operation of equipment. By understanding the properties and applications of different dielectric fluids, engineers and technicians can select the most suitable fluid for specific applications and optimize system performance.

Related Articles

Sign Up for Electricity Forum’s Dielectric Fluids Newsletter

Stay informed with our FREE Dielectric Fluids Newsletter — get the latest news, breakthrough technologies, and expert insights, delivered straight to your inbox.

A review of the fundamental dielectric characteristics of ester-based dielectric liquids

Fundamental dielectric characteristics describe permittivity, dielectric constant, polarization, loss tangent, conductivity, and frequency response, guiding material selection, insulating performance, impedance behavior, and electric field interactions across applications in electronics, power systems, and RF design.

What Are Fundamental Dielectric Characteristics?

Material metrics like permittivity, loss tangent, and polarization that govern insulating behavior under electric fields

✅ Determines energy storage via permittivity and dielectric constant

✅ Quantifies dissipation with loss tangent and conductivity

✅ Captures frequency response, polarization, and dielectric breakdown

1. Introduction

For many years synthetic ester fluids were seen as specialist materials, only for use in unusual transformers, such as those in rolling stock, offshore installations and steel plants where fire safety was a prime consideration. However, in more recent times users are realizing that ester-based liquids could offer a more mainstream alternative to mineral oil and although these fluids are more expensive the overall project costs can be lower when taking into account factors such as reduced fire protection. In some space-constrained urban environments ester-based liquids may even become the preferred option, with the flammability and potential environmental impact of mineral oil making the design of modern installations extremely challenging. This type of situation has been seen with the latest 400kV projects incorporating synthetic ester fluids. For context, readers can review the fundamentals of dielectric fluids to understand how base chemistry influences flammability and environmental performance.

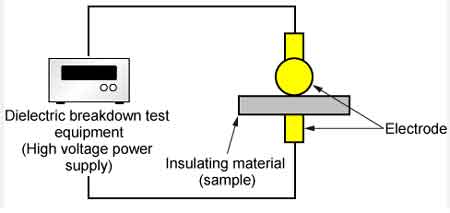

2. Standard AC Breakdown Testing

Standard test methods for assessing breakdown voltage of liquids typically employ small electrode gaps, of the order of ≤2.54mm. The electrode configuration can vary from spherical, through VDE type “mushroom” electrodes to disc electrodes. This type of testing is primarily used to give an evaluation of the cleanliness of a liquid since it gives very limited information about the actual dielectric performance. It can be seen by comparing the results in Table 1 that all the different types of liquids to be discussed in this paper give very similar results for a given electrode arrangement in this type of testing. Clarifying the definition of breakdown voltage in insulating oil helps interpret these short-gap results.

This could lead to the conclusion that all these liquids are equal in their dielectric performance, or that given a good result in the AC breakdown test one liquid is in some way superior to another. However, the true picture is more complex, since the electrical stress distribution is influenced by many factors such as electrode geometry, distance and materials types. Another key factor in the dielectric behavior is the wave shape of the applied voltage. AC voltage in the form of a clean sine wave is usually expected at frequencies of 50-60Hz depending on the geographical location. However, this is rarely the case with harmonics and other distortions of the pure waveform. In addition the prevalence of surges on the network must be accounted for; in testing this is usually characterized by two different types of event, either lightning surge or switching surge and there are standard waveforms established to test these.

In practice, understanding how oil in transformers behaves under distorted waveforms informs appropriate test selection.

So any dielectric system in a transformer must withstand AC conditions, switching impulse and lightning impulse, as well as chopped lightning impulse if this is specified. There may also be a requirement to withstand DC fields in some special cases and this adds an extra level of complexity.

When considering a new dielectric medium, therefore, all these aspects need to be tested and in the beginning researchers will look to comparisons with existing materials of known behavior to assess likely changes. As stated previously in terms of short gap AC behavior ester-based liquids are very similar to mineral oil and this gives some confidence that they can be used. For distribution class equipment up to 33kV the change to ester has required little in the way of detailed electrical design evaluation, since the electrical margins are large due to the need for excess solid insulation to provide mechanical strength. However as the voltage level rises there is less electrical margin and the need for routine impulse testing, both of which mean that greater steps are needed to evaluate design. So to begin using ester-based liquids in power class transformers there is a need to check impulse behavior over similarly short gaps to the AC tests, and this is where see some differences start to emerge.

Complementary programs of transformer oil analysis can track moisture, particles, and aging markers that strongly influence PD and impulse withstand.

3. Impulse Strength of Short Electrode Gaps

There are standard methods for measuring impulse breakdown with the ASTM D3300 being one popular method. The electrode arrangement for this test can be either needle to sphere, or sphere to sphere. In the first instance researchers started work with small electrode gaps employing a sphere-sphere set up, such as the example in Fig 1. utilized by the University of Manchester.

Fig.1. Arrangement for short gap impulse tests

In their testing, a number of different methods were applied for stepping up the test voltage, following the recommendations in different standards. This showed a lower impulse breakdown strength for the ester liquids and Fig 2. shows a summary of the results, with the maximum difference in breakdown voltage being of the order of 20%. In this case the mineral oil tested was Nynas Nytro Gemini X, the synthetic ester M&I Materials MIDEL 7131 and natural ester Cargill Envirotemp FR3. These observations are consistent with broader properties of transformer insulating oil related to ionization, space charge, and pre-breakdown dynamics.

Fig. 2. Results of impulse breakdown testing to various methods

4. Partial Discharge Inception

To further understand the mechanism behind the different behavior that was observed, researchers started looking at very divergent arrangements, for example a sharp needle of tip radius 6.5µm and sphere of radius 12.5mm, as this allows observation of phenomena in a liquid with manageable voltage levels.[3] This allowed the study of partial discharge inception, when the liquid begins to yield to the electrical field. When the researchers subjected this arrangement to AC they discovered that the PDIV of ester-based liquids with a gap of 50mm is actually very close to that of mineral oil.

In fact in the case of natural ester a higher PDIV was found than in mineral oil. This suggested that the reason for the difference in impulse breakdown behavior does not lie in discharge inception, although some different behavior was found in this study, especially in polarity, between mineral oil and esters. Mineral oil exhibits a very strong tendency to PD only in the positive half cycle of the AC waveform, i.e. when the needle is at a positive polarity. In the negative half cycle the required voltage to form PD is much higher than that of the PDIV. In the ester-based liquids the situation is somewhat different; PD was found in the negative half cycle at much closer voltages to the positive half cycle PDIV, as shown Fig. 3.

Fig. 3. PDIV in positive (left hand chart) and negative (right hand chart) half cycles

This indicated that the electrical behavior is not the same between the liquid types. It also throws up questions around the way mineral oil filled transformers are tested, i.e. is only testing with negative impulse a valid practice?

5. Streamer Propagation Behavior

The similarity in PDIV between esters and mineral oil required a closer look at propagation of electrical discharges. The next important step was then to look at the discharge channels in the liquids, known as streamers. This involved the combined techniques of electric measurement and visual imaging to detect how streamers form in liquids and how they propagate. Much of this work was conducted in parallel in different research institutions,where the same conclusion was drawn. Streamer propagation in esters is different to mineral oil, especially under very divergent fields, such as those the researchers were using. The key conclusion from this was a difference in so-called acceleration voltage when streamers move from slow mode propagation to fast mode.

In order for a flashover to occur it is necessary for the electrical current to find a path from one electrode to another and in liquids this occurs within a gaseous channel, known as a streamer. This channel will only propagate through the fluid if it has sufficient field strength to provide motive force and sufficient time. When considering AC behavior the time is relatively long, whereas under impulse conditions the time is extremely short. The standard wave shape for lightning impulse has a rise time of 1.2µs and fall time of 50µs to reach 50% of maximum. This means that the peak electrical field is only present for a matter of micro-seconds and in order to get propagation from one electrode to another, especially over longer oil gaps, the discharge must attain a high velocity. Streamers can be characterized by four different modes, as shown in Fig. 4.

Fig. 4. Streamer velocities and modes

The principle behind the connection between streamer mode and breakdown can be demonstrated with a simplified example. Taking a gap size of 50mm, if it is assumed that the liquid is only subjected to the voltage necessary to sustain propagation for 5µs then the streamer will need to attain a velocity of 10km/s or in other words be of Mode 3-4 to bridge the gap and cause a breakdown. Otherwise the streamer will only be characterised as a partial discharge. The transition from Mode 1/2 to Mode 3/4 can be characterised as the acceleration voltage.

A variety of researchers have looked at the acceleration voltage principle with esters and all agree that this is one area where these liquids differ from mineral oil. The charts in Fig. 5. show the behavior when the electrode system is extremely divergent, with esters having a substantially lower acceleration voltage than mineral oil, especially under positive polarity.

Fig. 5. Acceleration voltage under Positive polarity and Negative polarity at 50mm spacing

6. Testing with More Realistic Electrode Arrangements

Although this difference in acceleration voltage would appear to prevent the use of esters at higher voltages as the electrode arrangement becomes less divergent, inception begins to become more important for the withstand level. This supports the findings of researchers who have studied the behavior with varying levels of divergence in the electrodes, from homogenous through to highly divergent.

When thinking about the design of real world equipment and transformers for transmission levels, the more homogeneous case actually represents the majority of the configurations to be considered. Needle to plate type situations are avoided as part of good design and manufacturing, as it is known that these are electrically weak and prone to producing discharges. Consequently, criteria for selecting oil for transformers should consider field uniformity, surge exposure, and insulation geometry as well as fire safety.

Research looking at impulse behavior under more realistic arrangements has focussed on tap changer contacts, since these represent a more divergent part of power transformer designs. In this case the arrangement shown in Fig. 6. was used and the results obtained under impulse conditions showed very little difference between ester and mineral oil.

Fig. 6. Tap changer contacts used for natural ester evaluation

Fig. 7. shows the Weibull distribution for results obtained in this arrangement. This gives some confidence that even though the situation with a needle and plate looks unfavourable, as soon as the configuration starts to reflect the real world situation, the difference between esters and mineral oil becomes much smaller.

Fig. 7. Weibull distribution of lightning impulse breakdown under positive polarity

7. Laboratory Testing of Creepage Discharge and Flashover

Another area where divergence becomes important is over long creepage paths, where there is effectively a concentrated area of electrical field at one end, with a very long distance to the lower potential. A popular form of arrangement for testing creepage behavior is the so-called Weidmann set up, of a paper-wrapped or bare conductor in contact with a pressboard barrier, as shown in Fig 8.

Fig. 8. Weidmann electrode arrangement

When this type of arrangement has been tested over gap sizes up to 35mm it has been found that esters give similar flashover results to mineral oil, as shown in Table 3. The difference between the liquids in this arrangement is small - not even as large as that found in small oil gaps. This suggests that even though design modification may be necessary, there is not the very large difference that might be assumed if the acceleration voltage in extremely divergent set up was used.

8. Testing in Prototype Transformers

Another area where more focus may be required with an ester based liquid is over very long creepage paths far beyond the distances tested with the Weidmann arrangement, since the fundamental investigations indicate that propagation is key. Experience from real transformer prototypes has shown that failure modes over extremely long paths support the faster propagation model. Researchers from Brazil found that when testing a single phase 245kV prototype transformer, in natural ester, designed to mineral oil rules, the natural ester failed at 100% of Basic Insulation Level (BIL) rating, when tested with lightning impulse along a long gap discharge path, as shown in Fig.

3. This unit had an HV winding with a center connection coil.

Fig. 9. Model of winding showing discharge path

The designers of this transformer noted that although they experienced this failure it does not prevent the use of esters at higher voltage. However, there may need to be more design margin and closer attention paid to peak stress areas and long creepage paths. Thermal design and transformer cooling also affect viscosity and bubble formation, which in turn impact dielectric margins at high stress.

This is a theme that is often mentioned in the industry when discussing ester-based liquids and the necessary design changes. It is important to note that a growing number of manufacturers have carried out their own research in addition to the published works; to date there are a number of transformers successfully operating at 400kV+ with esters. There are also many other projects in development, and the expectation is that in the coming years esters will move from a being a product used in niche applications to one deployed in mainstream installations.

9. Conclusions

Over the last fifteen years a great deal of research has been conducted into understanding the electrical behavior of ester-based liquids, under a range of different conditions. This has been driven by a desire for safer, more environmentally friendly transformers.

The laboratory based test arrangements with extremely divergent fields indicate a difference in the streamer propagation behavior between esters and mineral oil, which may mean designers need to pay attention to certain portions of the dielectric structure. Evaluations with more realistic electrode arrangements indicate that although there is a difference in behavior, this will not prevent the use of esters at higher voltages. The experience in real world applications, where esters are now utilized for power transformers for 400kV+ also supports this assertion.

The key aspects for designers when considering ester-based liquids are to design a discharge-free transformer; extra margin may be needed over long creepage paths and in divergent arrangements to compensate for the higher probability of propagation. This could be summarized by saying that with mineral oil, discharges may occur, without flashover, but in ester there is a higher probability of discharge becoming breakdown.

Related Articles

Oil in Transformers - An Insulating Medium

Oil in transformers plays a critical role as a cooling and insulating medium which directly impacts the efficiency, performance, and lifespan, which are essential components of the power grid. Understanding its properties, maintenance requirements, and failure indicators can help professionals prevent costly outages and enhance grid reliability. Let's explore the key functions of dielectric fluid, common issues such as contamination and aging, and best practices for testing and maintenance, equipping readers with the knowledge to optimize device performance and safety.

Electrical Transformer Maintenance Training

Substation Maintenance Training

Request a Free Training Quotation

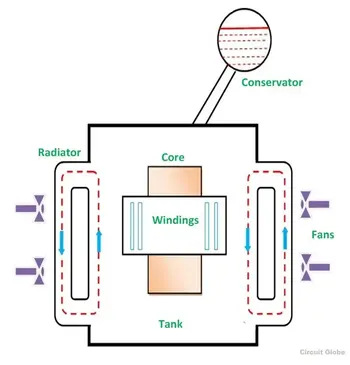

The Dual Function of Transformer Oil

The primary function of transformer-based oils is to provide both insulation and cooling. As the device operates, heat is generated from the core and coils due to electrical losses. Device liquid, typically filled with mineral oil or similar insulating fluid, absorbs this heat and dissipates it efficiently, thus preventing overheating. Moreover, it serves as an insulating material, maintaining the dielectric strength required for safe operation. The high dielectric strength of the liquid prevents electrical arcing or short circuits between components within the device, ensuring that the unit functions reliably. This dual-purpose function of the oil contributes significantly to the device’s ability to operate for extended periods without failure, reducing the risks of overheating and electrical faults.

Electrical insulating materials play a crucial role in maintaining the efficiency and safety of transformers by managing heat from the core and coils. Among the most commonly used materials, paper insulation provides effective thermal and electrical resistance, ensuring stable performance under operational stresses. Solid insulation, such as epoxy or resin-based materials, complements paper insulation by adding structural integrity and resistance to mechanical and thermal degradation. Together, these insulating systems work to optimize heat dissipation and prevent electrical faults, safeguarding equipment longevity and reliability.

Types of Transformer Oils

However, not all device oils are created equal. There are two main types of fluids used in devices: uninhibited oil and inhibited oil. Uninhibited liquid lacks additives that can slow down its natural degradation, making it more prone to breakdown over time. On the other hand, the inhibited liquid is enhanced with oxidation inhibitors that increase its resistance to degradation. This makes the inhibited liquid ideal for modern devices, where long-term stability and performance are crucial. As devices continue to serve in industrial and power distribution systems, the type of fluid used in each unit plays a direct role in its efficiency, lifespan, and overall environmental impact.

The Importance of Regular Testing and Quality Assessment

When it comes to device liquid, regular testing is essential to ensure that it maintains its properties over time. One of the most critical tests conducted is the dielectric breakdown voltage test, which measures thermal conductivity and the liquid's ability to withstand electrical stress without breaking down. This test ensures that the liquid can continue to insulate effectively under high-voltage conditions. Another important analysis is the Dissolved Gas Analysis (DGA), which detects gases dissolved in the liquid. The presence of certain gases can indicate internal faults, such as overheating or arcing, which could lead to a device failure. By performing regular tests, maintenance teams can identify potential issues early and take corrective action before they escalate into significant problems.

Environmental Considerations and the Shift Toward Sustainable Oils

Environmental considerations also come into play when selecting liquid for the device. Traditional mineral oils, while effective, pose certain environmental risks, such as fire risk and potential toxicity in the event of spills. As a result, alternative, environmentally friendly options, such as natural esters, are gaining popularity. These bio-based liquids and dry type transformers are derived from renewable sources and offer better biodegradability, making them a more sustainable option compared to conventional mineral oils. Additionally, their higher flash point reduces the fire risk associated with device operation, further contributing to the safety of electrical installations. However, while natural esters present a promising alternative, their adoption is still growing, and they are not yet as widespread as mineral oils.

Maintenance and Purification of Transformer Oil

As with any fluid used in electrical equipment, device liquid requires periodic maintenance and purification. Over time, device liquid can deteriorate due to oxidation, external contamination, or electrical stress breakdown. To ensure that the liquid retains its properties, purification techniques such as filtration or vacuum treatment are employed. These methods remove contaminants and restore the liquid’s insulating properties, helping to extend the life of the device. By maintaining the quality of the insulating liquid, power companies can avoid costly repairs and ensure that their devices continue to function efficiently for years.

Frequently Asked Questions

Which oil is used in the transformer?

The liquid used in devices is typically a type of mineral oil, which is specifically refined and treated to meet the insulating and cooling requirements of devices. However, natural esters, which are derived from renewable plant sources, are increasingly used as an environmentally friendly alternative. These liquids are selected for their high dielectric strength (the ability to resist electrical breakdown) and their ability to dissipate heat efficiently from the device's internal components.

What is the oil inside a transformer?

Oil filled transformers are dielectric fluid, meaning it does not conduct electricity and serves primarily to insulate the electrical components from each other. This liquid helps prevent electrical arcing and short circuits. In addition to its insulating properties, the insulating oil also acts as a cooling agent, absorbing and dissipating heat generated by the electrical currents passing through the device's core and coils. The liquid helps maintain the device at a safe operating temperature, preventing overheating and damage to the internal components.

How to maintain transformer oil?

To maintain liquid, regular testing is essential to monitor its dielectric strength, moisture content, and dissolved gases, which can indicate internal issues. Filtration and vacuum treatment help purify the liquid by removing contaminants like sludge, moisture, and gases. Monitoring liquid levels is crucial to ensure proper insulation and cooling while addressing leaks or evaporation. Over time, liquid may need to be replaced or upgraded, especially if it has degraded or become contaminated. By following a routine maintenance schedule, including inspections and necessary treatments, device liquid can be kept in optimal condition, ensuring the device operates safely and efficiently.

What happens if there is no oil in a transformer?

If a device runs without liquid or if the liquid level becomes too low, several critical problems can occur. The device would lack the necessary insulation and cooling properties provided by the liquid. Without adequate insulation, electrical arcing could occur, leading to short circuits or even fires. Additionally, the device would overheat because there would be no liquid to absorb and dissipate the heat generated by the electrical currents. Overheating can damage the device’s internal components, reduce its efficiency, and ultimately lead to the complete failure of the device. Therefore, maintaining an adequate liquid level is essential for a device's safe and efficient operation.

Oil in devices plays a critical role in both insulation and cooling, ensuring the efficient operation and longevity of the device. It acts as an insulating fluid, preventing electrical faults by maintaining a high dielectric strength, and absorbs heat generated during operation, preventing overheating. Equipment liquid can be mineral liquid or natural esters, with the latter being an environmentally friendly alternative. Regular maintenance, including testing for dielectric strength, moisture, and dissolved gases, along with purification methods like filtration and vacuum treatment, is necessary to keep the liquid effective. Proper oil management helps extend device lifespan, reduce risks of failure, and ensure safe, reliable operation in electrical systems.

Dissolved Gas Analysis Of Transformer Oil

Dissolved Gas Analysis (DGA) is a key diagnostic tool for transformers, evaluating dissolved gases in insulating oil to identify overheating, arcing, partial discharge, and insulation breakdown. It enables predictive maintenance, improves power system reliability.

What is Dissolved Gas Analysis?

Dissolved Gas Analysis is a diagnostic method that evaluates gases in transformer insulating oil to identify electrical faults and ensure reliable operation.

✅ Detects partial discharge, arcing, and overheating

✅ Guides predictive maintenance and fault prevention

✅ Improves transformer reliability and system safety

DGA is a crucial tool for electrical engineering and maintenance professionals, providing vital insights into the health of transformers and other high-voltage assets. By detecting gases produced during insulation degradation or electrical faults, it offers early warning signs of potential failures. Proactive detection through DGA allows utilities and industries to prevent unplanned outages, extend equipment lifespan, and strengthen system reliability. As a cornerstone of condition-based maintenance, mastering DGA is essential for maintaining high-performance electrical infrastructure. Understanding dissolved gas analysis begins with the role of dielectric fluids, as the composition of transformer oil directly influences gas formation and the accuracy of fault detection.

Electrical Transformer Maintenance Training

Substation Maintenance Training

Request a Free Training Quotation

Transformer Fault Diagnosis

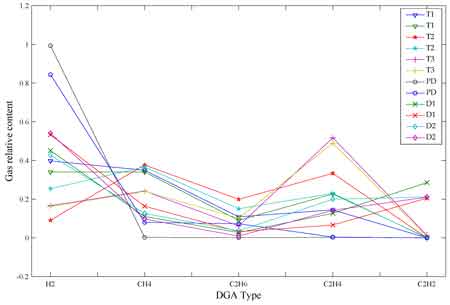

One of the key applications of DGA is transformer fault diagnosis. Under normal operating conditions, only trace gases form. During faults, such as partial discharge or arcing, heat and stress decompose insulating oil and cellulose, generating gases such as hydrogen, methane, ethane, ethylene, acetylene, carbon monoxide, and carbon dioxide.

-

Hydrogen (H₂): partial discharges

-

Methane (CH₄): low-temperature overheating of cellulose

-

Ethane (C₂H₆) and Ethylene (C₂H₄): higher-temperature thermal faults

-

Acetylene (C₂H₂): arcing

-

CO and CO₂: insulation paper degradation

The concentration and ratio of these gases provide a fingerprint of the fault type. Experts can distinguish between thermal faults, partial discharge, and severe arcing, enabling timely maintenance. New research highlights advancements in DGA data quality, improving reliability and reducing errors in transformer fault diagnosis.

Interpretation Methods and Fault Classification

Accurate interpretation is central to DGA. Several methods have been standardized:

-

Ratio Methods: Rogers and Doernenburg use gas concentration ratios to classify fault types.

-

Duval Triangle / Pentagon: graphical techniques plotting gas ratios (e.g., H₂:CH₄:C₂H₆) to identify fault zones (partial discharge, low/high thermal faults, arcing).

-

IEC 60599 and IEEE C57.104 Standards: provide threshold limits, diagnostic ratios, and guidelines for reporting and action.

Example: Using the Duval Triangle, a mixture rich in acetylene indicates arcing, while high ethylene levels suggest a high-temperature thermal fault.

Emerging methods, such as fuzzy logic and expert systems, refine interpretation when faults overlap, thereby enhancing the accuracy of fault detection. AI and machine learning now enhance accuracy, reducing misclassification in complex cases. Engineers applying DGA can benefit from recent advancements in dissolved gas analysis, which refine fault classification methods through better interpretation of gas ratios.

Case Study Example

A 230 kV transformer recorded abnormal gas levels:

-

H₂ = 750 ppm

-

CH₄ = 120 ppm

-

C₂H₆ = 40 ppm

-

C₂H₄ = 260 ppm

-

C₂H₂ = 15 ppm

-

CO = 900 ppm

Interpretation: The high hydrogen, ethylene, and carbon monoxide levels suggest a high-temperature thermal fault with cellulose insulation degradation. Using the Duval Triangle, this case falls into a “thermal fault >700°C” zone. Preventive maintenance avoided catastrophic failure. Specialists often review the CO/CO₂ ratio in dissolved gas analysis, since carbon gases provide unique insights into cellulose insulation degradation.

Predictive Maintenance

Predictive maintenance is another significant advantage of DGA. Since transformers are essential but costly assets, unplanned downtime can be financially devastating. Through DGA, utilities and industrial operators can predict when maintenance is required, rather than reacting to sudden failures. DGA monitors provide real-time tracking of gas concentrations, enabling maintenance teams to act before a minor issue becomes a major outage.

DGA shifts maintenance from a reactive to a predictive approach. By monitoring gas concentration trends, utilities can:

-

Predict when interventions are needed

-

Extend transformer service life

-

Reduce operational costs and outages

Continuous monitoring ensures that problems are addressed before they escalate into system failures. By pairing dissolved gas analysis with condition monitoring in an age of modernization, utilities can transition from reactive repairs to predictive maintenance strategies.

Gas Chromatography

DGA relies on gas chromatography, which separates and quantifies individual gases. A sample of insulating oil is processed to measure the concentrations of hydrogen, methane, ethane, ethylene, acetylene, carbon monoxide, and carbon dioxide in parts per million (ppm). This precision enables consistent results across laboratories and forms the foundation of DGA reporting. Gas concentrations revealed through DGA provide insights that complement power transformer health check programs, ensuring reliable performance of these critical assets.

IEC Standards and Key Gases

International Electrotechnical Commission (IEC) standards play a pivotal role in ensuring consistency and accuracy in dissolved gas analysis. These standards provide guidelines for the collection, handling, and analysis of oil samples, as well as for the interpretation of results. By following IEC standards, utilities and maintenance teams can achieve more reliable and comparable DGA results across different transformers and facilities. This uniformity helps ensure that decisions regarding maintenance and repair are based on accurate, standardized data.

Key gases such as hydrogen, methane, ethane, ethylene, and acetylene are essential to understanding the types of transformer faults. For example, the presence of acetylene often points to arcing, while ethylene and ethane are indicators of high-temperature thermal faults. Hydrogen is commonly associated with partial discharge, while methane is linked to overheating of cellulose insulation. Recognizing the role of these key gases allows technicians to identify specific transformer problems, prioritize maintenance, and avoid costly failures.

International standards ensure consistency.

-

IEC 60599: guidance on sampling, analysis, and interpretation.

-

IEEE C57.104: fault classification tables and gas thresholds.

Example gas thresholds (ppm):

| Gas | Normal | Caution | Dangerous |

|---|---|---|---|

| Hydrogen (H₂) | <100 | 100–700 | >700 |

| Acetylene (C₂H₂) | <1 | 1–10 | >10 |

| Ethylene (C₂H₄) | <50 | 50–200 | >200 |

Limitations and Caveats

While powerful, DGA has limits:

-

Cannot localize the exact fault location

-

Oil replacement can reset the gas history

-

Mixed faults produce ambiguous results

-

Stray gassing may occur at low temperatures

-

Sampling and handling errors can skew results

DGA should complement other diagnostics, such as dissolved moisture analysis, partial discharge monitoring, or infrared thermography. Dissolved gas analysis also supports the broader maintenance of substation transformers, where continuous monitoring is essential to preventing costly power disruptions.

Real-Time Monitoring

DGA monitors are essential tools for continuous tracking of gas levels in transformer oil. Unlike periodic sampling, DGA monitors operate in real-time, offering immediate insight into any changes in dissolved gases. By continuously observing gas concentrations, operators gain a deeper understanding of the transformer's condition, enabling swift responses to abnormal readings. Continuous tracking helps utilities maintain system reliability and prevent emergency shutdowns.

Online DGA monitors provide continuous tracking of gas levels, feeding data into SCADA and asset management systems. Unlike periodic lab sampling, online systems detect rapid changes, offering:

-

24/7 protection for critical transformers

-

Faster fault detection and intervention

-

Integration with predictive analytics dashboards

Though more costly, real-time systems are invaluable for utilities managing large fleets of high-value transformers.

Advanced Analytics and AI

Recent research applies machine learning and deep learning to improve DGA interpretation. Models such as convolutional neural networks (CNNs), ensemble classifiers, and copula-based correlation methods identify fault patterns with greater accuracy. Studies (2023–2025, Nature, MDPI, arXiv) show AI can detect stray gassing and overlapping fault signatures earlier than classical methods. Combining traditional ratios with AI enhances both precision and reliability.

Frequently Asked Questions

When should transformers be retested with DGA?

Typically, every 6–12 months for routine testing, but more frequently if abnormal gas levels are detected or if online monitors show sudden changes.

How do you choose a DGA monitor?

Consider transformer criticality, cost, required gases, calibration frequency, and SCADA compatibility.

What is the minimum oil sample size?

About 50–100 mL is typically required for laboratory gas chromatography.

What role does cellulose insulation play in gas generation?

Breakdown of cellulose produces CO and CO₂, indicating paper degradation in addition to oil fault gases.

Can DGA predict all failures?

No. While highly effective, it should be combined with other diagnostics for complete transformer condition monitoring.

Related Articles

Transformer Insulating Oil

Transformer Insulating Oil provides dielectric insulation, arc suppression, and cooling for power transformers, improving efficiency, preventing electrical faults, reducing downtime, and ensuring reliable high-voltage system performance in energy distribution networks.

What is Transformer Insulating Oil?

Transformer insulating oil is a vital fluid that plays a crucial role in the reliable and efficient operation of electrical power systems.

✅ Provides electrical insulation and suppresses arcing between components

✅ Dissipates heat to prevent transformer overheating and failure

✅ Protects against moisture, oxidation, and other contaminants

It serves as the lifeblood of power transformers, providing essential insulation, cooling, and arc-quenching properties. A deep understanding of the fluid's characteristics, functions, and maintenance requirements is essential for electrical engineers, technicians, and maintenance professionals to ensure the optimal performance and longevity of these critical components. To learn more about the role of dielectric fluids in transformer insulation and cooling, visit our main page on Dielectric Fluids.

Electrical Transformer Maintenance Training

Substation Maintenance Training

Request a Free Training Quotation

The essential role of transformer insulating oil in electrical power distribution systems cannot be overstated. This insulating fluid plays a vital role in ensuring transformers' efficiency, safety, and longevity. It is a crucial insulating material that supports electrical stability while also providing thermal management and arc-quenching capabilities. Without it, transformers would face higher risks of failure, overheating, and electrical breakdowns. For insight into cutting-edge techniques for fault detection, see our detailed guide on Advancements in DGA Data Quality.

One of the most critical aspects of this kind of dielectric fluid is its ability to act as an excellent electrical insulating medium. By filling the space around the core and coils, it prevents electrical arcing and ensures a high dielectric strength. This high dielectric strength is essential for maintaining insulation integrity under high-voltage conditions. The breakdown voltage of the insulating fluid must be tested regularly to ensure it retains its insulating properties. Testing procedures, such as dielectric strength testing and dissolved gas analysis (DGA), are used to identify potential issues and help maintain service life. Discover how dissolved gas patterns reveal transformer health in our technical article on Advancements in Dissolved Gas Analysis.

The properties of a dielectric fluid vary depending on its type. Mineral oil remains one of the most widely used types of transformer dielectric fluid due to its affordability, availability, and decent insulating performance. However, it’s not the only option. Synthetic ester oils offer a more sustainable and fire-resistant alternative. These oils have a high fire point, making them safer for use in sensitive environments where fire hazards must be minimized. Silicone-based dielectric fluids, on the other hand, are known for their ability to remain stable at high temperatures, offering an advantage in environments with extreme heat.

Insulation and Cooling

Another critical role of transformer insulating oil is heat dissipation. The design of transformers enables efficient heat transfer, allowing the insulating fluid to absorb and dissipate heat generated by the core and coils. This heat management is crucial for extending the service life. An essential property that supports this function is the pour point of the fluid, which ensures it remains fluid even at low temperatures. Fluid with a low pour point maintain fluidity, ensuring effective heat dissipation in colder climates. Dive deeper into diagnostic gas trends with our exploration of CO/CO₂ Ratio Analysis as an indicator of cellulose insulation degradation.

Arc Quenching and Oxidation Resistance

Regular transformer testing and maintenance are essential to maintaining the effectiveness of dielectric fluids. Filtration and purification are critical to remove contaminants, moisture, and gases that accumulate over time. Oxidation stability is one of the most important factors influencing the service life of the fluid. When oxidation occurs, it can form acids and sludge, which degrade the dielectric fluid's insulating properties and reduce its effectiveness. Regular filtration processes ensure the insulating oil remains pure and retains its excellent electrical insulating capabilities.

Testing and Maintenance

Regular testing and maintenance are essential to maintaining optimal performance and reliability. Dielectric strength testing measures the dielectric fluid's ability to withstand electrical stress, while dissolved gas analysis (DGA) identifies potential faults within the unit by analyzing the gases dissolved. Fluid filtration and purification techniques remove contaminants and moisture, prolonging the dielectric fluid's service life.

Types of Transformer Oil

Various types are available, each with its own specific characteristics. Mineral oil, a traditional choice, is derived from petroleum and offers a balance of performance and cost-effectiveness. However, it is susceptible to fire and environmental concerns. To address these issues, synthetic ester oils have emerged as a superior alternative. These dielectric fluids exhibit excellent fire resistance, high dielectric strength, and superior oxidation stability. They are also environmentally friendly and biodegradable. Silicone oil, another synthetic option, offers exceptional thermal stability and arc-quenching properties, making it suitable for high-temperature applications.

Environmental Impact and Safety

Environmental sustainability has also become a key consideration in the selection and management of dielectric fluid. Traditional mineral oil has environmental drawbacks, such as limited biodegradability and disposal challenges. Biodegradable types, such as synthetic ester oils, are now being used as environmentally friendly alternatives. These dielectric fluids offer the dual benefits of reducing environmental impact and providing high fire resistance. Moreover, responsible recycling and disposal practices for used transformer fluids are mandated by regulatory compliance standards to protect the environment.

Safety is a paramount concern when dealing with dielectric fluid. As the dielectric fluid circulates inside, it’s crucial to understand the risks associated with fire hazards. The flash point of a dielectric fluid is a key indicator of its fire resistance. Dielectric fluids with a high fire point are preferred in applications where fire safety is a priority. Emergency response procedures must also be established in the event of spills or leaks, ensuring that spills are contained quickly to prevent environmental contamination. Additionally, health and safety measures are critical for workers handling dielectric fluid. Direct exposure can pose health risks, requiring protective equipment and following established handling protocols. For additional context on cooling mechanisms and thermal performance, read our article on Transformer Cooling and Dielectric Fluids.

Frequently Asked Questions

What is another name for transformer oil?

Another name is insulating or dielectric fluid. It is also sometimes referred to as dielectric fluid because of its role as a dielectric material that prevents electrical discharges inside. In specific contexts, names like mineral-insulating dielectric fluid or ester-based insulating dielectric fluid may be used to specify the type of oil used.

Can I use transformer oil on my skin?

No, it is not recommended to use dielectric dielectric fluid on your skin. This oil is not designed for human contact and may contain chemical additives, contaminants, or degradation products that can irritate the skin. Prolonged exposure to certain types of mineral oil can pose health risks. Any exposure should be washed off immediately with soap and water for health and safety reasons.

What is the real name of transformer oil?

The real name depends on its composition. Most dielectric fluids are referred to as mineral insulating oil or naphthenic mineral oil. Biodegradable alternatives may be called natural ester insulating dielectric fluid or synthetic ester insulating oil. For example, common mineral oil used is a type of naphthenic oil, while modern, environmentally friendly units may use ester-based oils.

Transformer dielectric fluid is a vital component in electrical power distribution, playing a central role in insulation, cooling, arc quenching, and overall safety. The choice of dielectric fluid—whether mineral, synthetic ester, or silicone—depends on application requirements, safety considerations, and environmental impact. Regular testing, maintenance, and proper disposal methods ensure its continued performance and compliance with regulatory standards. By maintaining oxidation stability and leveraging dielectric fluids with a high fire point, operators can ensure the longevity and safety in various industrial and commercial settings.

Transformer Cooling

Transformer cooling enhances thermal management via oil-immersed and air-cooled systems, radiators, fans, and pumps. Methods like ONAN, ONAF, and OFAF reduce temperature rise, limit insulation aging, and improve efficiency under varying load.

What Is Transformer Cooling?

Transformer cooling removes heat from windings and core via oil or air circulation to control temperature and slow aging.

✅ Common types: ONAN, ONAF, OFAF, OFWF for various ratings.

✅ Components: radiators, fans, oil pumps, heat exchangers.

✅ Benefits: lower temperature rise, higher efficiency, longer life.

A little energy lost in a transformer must be dissipated as heat. Although this energy is but a small portion of the total energy undergoing transformation, it becomes quite large in amount in transformers of larger kVA ratings. To maintain efficiency and life expectancy the transformer's cooling system needs to be operating at peak performance. For dry-type transformers, the ventilation system of the room should be inspected to make sure it is operating efficiently. For forced air-cooled systems, the fan motors should be checked for proper lubrication and operation. Water-cooled systems must be tested for leaks and proper operation of pumps, pressure gauges, temperature gauges and alarm systems.

In liquid-filled designs, the choice and maintenance of oil in transformers directly influence heat removal performance and long-term reliability.

When a liquid coolant is used its dielectric should be tested. Water in the coolant will reduce its dielectric strength and the insulation quality. In cases where the dielectric strength of the coolant is reduced significantly, conducting arcs may develop causing short-circuits when the transformer is energized. A standard oil dielectric test involves applying high voltage to a sample taken from the transformer and recording the voltage at which the oil breaks down. If the average breakdown voltage is less than 20 kilovolts, the oil will need to be filtered until a minimum average breakdown of 25 kilovolts is achieved. Technicians often reference breakdown voltage of oil guidelines to interpret test results and schedule remediation.

Comprehensive transformer oil analysis can reveal moisture ingress, dissolved gases, and particulate contamination before failures occur.

Oil-insulated transformers use mineral oil for cooling. This oil is thin enough to circulate freely and does a good job of providing insulation between the transformer windings and the core. It is however subject to oxidation and if any moisture enters the oil, its insulating value is substantially reduced. In addition, mineral oil is flammable and therefore should not be located near combustible materials indoors or outdoors. In critical applications, selecting a high-quality transformer insulating oil mitigates oxidation, moisture effects, and thermal aging.

These behaviors align with the fundamental dielectric characteristics that govern insulation performance under electrical and thermal stress.

There are several types of transformer oil cooling solutions:

- oil air

- forced oil

- oils water

- oil natural

- air forced

- heated oil

- oil forced

- natural

In practice, each configuration must be evaluated alongside the properties of the chosen dielectric fluid to balance cooling effectiveness, safety, and service life.

Outdoor liquid-cooled transformers usually use mineral oil, and liquid cooled transformers for inside use are filled with a synthetic liquid that is nonflammable and nonexplosive. Synthetic oil coolants must be handled with care as they sometimes cause skin irritations. One type, askarelinsulated transformers used in past years contained polychlorinated biphenyls (PCBs), which are known to cause cancer. Askarel has been banned by the Environmental Protection Agency and its use as a transformer coolant is being phased out. However, askarel coolants are still found throughout the electrical industry in older transformers and direct contact with them should be avoided. The NEC still contains provisions for installing askarel transformers. The following is a list of the different types of liquid-filled transformers recognized by the NEC:

Facility engineers should review application requirements, fire codes, and material compatibility when selecting oil for transformers to ensure compliance and dependable operation.

- Oil-Insulated--uses chemically untreated insulating oil

- Askarel—uses nonflammable insulating oil

- Less-Flammable Liquid-Insulated--uses reduced flammable insulating oil

- Nonflammable Fluid-Insulated--uses noncombustible liquid

Related Articles

Advancements in Dissolved Gas Analysis: Data Quality

Advancements in DGA data quality enable precise transformer monitoring, dissolved gas analysis, and predictive maintenance through calibrated sensors, IEC 60599/IEEE C57.104 harmonization, machine-learning analytics, anomaly detection, and IEC 61850-integrated SCADA data integrity.

What Are Advancements in DGA Data Quality?

Enhanced DGA data quality strengthens transformer diagnostics via calibrated sensors, aligned standards, and analytics.

✅ On-line oil monitors with auto-calibration and drift correction

✅ IEC 60599/IEEE C57.104 harmonized thresholds and diagnostics

✅ ML-based anomaly detection and condition-based maintenance

Introduction

There is more to DGA interpretation than comparing the latest gas concentrations to limits in a table or plotting them in a triangle or pentagon to identify the apparent fault type. We have found that the whole DGA history of a transformer must be considered when interpreting its most recent DGA results.

Trend evaluation and accurate assessment of short-term changes require accuracy and low measurement variability of gas data. Data quality problems must be recognized and dealt with before an interpretation is attempted. Below we point out some of the most common data quality issues. For broader context on diagnostics, the primer on dissolved gas analysis outlines core fault signatures, typical gas sources, and interpretation pitfalls.

Understanding how oil and paper behave electrically is foundational, and the summary of fundamental dielectric characteristics helps explain why certain gases trend together over time.

Data management

As a result of the historical importance of DGA data, proper organization and preservation of DGA data are extremely important. In addition to archiving the lab reports, keep the data in tabular form in a database or, for small volumes of data, a spreadsheet. A well-organized database supports sorting and filtering for graphical and statistical analysis.

Use a unique and permanent ID to identify transformers, oil compartments, and the oil sample data belonging to them. Substation and unit number are not a suitable ID, for the same reason that the dentist doesn’t identify you by your department and job title. Large transformer fleets may require company-assigned asset numbers to avoid possible serial number duplication across manufacturers.

Disciplined chain-of-custody practices provide correct IDs of transformers and compartments to be sampled, ensure that oil samples are labeled correctly, and guarantee that analysis results returned by the lab are attributed to the right transformers and oil compartments. Integrating laboratory reports with a structured repository is easier when guided by practical notes on transformer oil analysis data formats and decision thresholds.

For sampling logistics and labeling discipline, operations teams can review guidance on oil in transformers to align maintenance practices with data management goals.

Data inconsistency or inaccuracy

Gas loss that is deliberate, such as by head space pressure regulation or use of a desiccant breather, needs to be accounted for as discussed in our other article [1]. Unintended gas leakage from a transformer – often detectable by a O2/N2 ratio persistently above 0.2 when it should be lower – should be remedied as soon as possible, both to keep DGA effective and to prevent moisture ingress. After oil degassing, it is advisable to exclude samples from DGA interpretation for 6-12 months due to the false upward trends created by diffusion of gases from winding paper into the bulk oil.

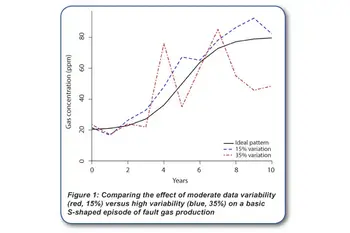

Accuracy and repeatability of gas data are only partly up to the laboratory. Unrepresentative oil samples can lead to inconsistent and highly variable gas data regardless of the quality of laboratory measurements. A study by a large USA electric utility [2] shows that using extra care and a moisture / temperature probe to ensure collection of representative oil sample can reduce data variability considerably. The figure (Figure 1) illustrates the effect of moderate variability (±15%) versus high variability (±35%) on the data from a basic S-shaped gassing event.

Moderate variability is experienced with consistently good sampling practice and a good laboratory. High variability is easily attainable if there is a problem with sampling practices. Recent field case studies on advancements in dissolved gas analysis discuss accounting for gas loss, diffusion effects, and sampling bias.

When evaluating short-term changes following maintenance, further techniques described in advancements in DGA interpretation can reduce false alarms by emphasizing trend shape over single-point limits.

The table provides a summary of some common data quality problems. Sections 5.1 and 5.2 of IEEE C57.104-2019 [3] contain a detailed discussion of data quality assessment. For paper-aging diagnostics specifically, insights on the CO/CO2 ratio in DGA clarify when cellulose decomposition is the likely source.

References

[1] “Advancements in Dissolved Gas Analysis: Accounting for Gas Loss,” Electricity Today, March 2020

[2] T. Rhodes, “Using field moisture probes to ensure drawing a representative oil sample,” in 82nd Annual International Doble Client Conference, Doble Engineering Company, March 2015.

[3] “IEEE Guide for the interpretation of gases dissolved in mineral oil filled transformers”, IEEE Std C57.104-2019.