Latest Smart Grid Articles

How utilities can keep the lights on

How utilities can keep the lights on? Strengthen grid resilience with smart grid upgrades, demand response, distributed energy resources, predictive maintenance, cybersecurity, and enhance outage management, load forecasting, and renewable integration to ensure reliability.

How Utilities Can Keep the Lights On?

By modernizing the grid, diversifying supply, and optimizing demand with smart systems to ensure reliable service.

✅ Implement demand response, DRMS, and AMI to balance peak loads

✅ Deploy microgrids and battery storage for outage resilience

✅ Use predictive maintenance, SCADA, and analytics to cut downtime

Utilities worldwide have been on a roller-coaster ride, and an often painful one, over the past decade. Despite the sharp growth in global demand for electricity, many utilities have lost value or posted below-average returns. A McKinsey analysis of 50 major publicly listed utilities from Asia, Europe, and North America showed average total cumulative returns to shareholders of about 1 percent from July 2007 to July 2017, compared with 55 percent for the MSCI World Index.

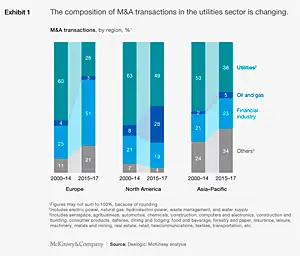

Utilities with high exposure to merchant revenues did even worse. Two reasons stand out. First, the collapse of merchant conventional generation eroded profits in Europe and the United States, and the growth in other sectors, such as renewables and transmission and distribution (T&D), was not enough to compensate. Second, utilities worldwide are losing market share to entrants from new sectors, such as the financial industry and the oil and gas industry (Exhibit 1). In the next decade, we expect electricity demand to increase faster than any other kind of energy, due to economic growth in Africa, Asia, and Latin America, and the electrification of final energy demand, specifically in transportation and heating. Massive new investments will be needed to keep up.

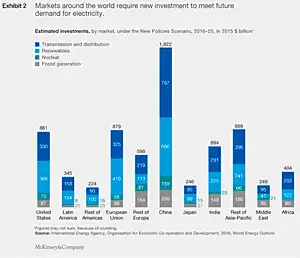

In the next decade, we expect electricity demand to increase faster than any other kind of energy, due to economic growth in Africa, Asia, and Latin America, and the electrification of final energy demand, specifically in transportation and heating. Massive new investments will be needed to keep up.

The International Energy Agency (IEA) estimates that from 2016 to 2025, there will be $7.2 trillion in investment in the power sector (Exhibit 2), almost $1.0 trillion more than in the previous decade.

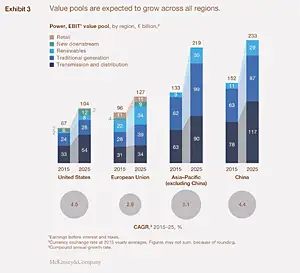

This could help utilities to improve their performance and create value—and in fact this may be happening for some large utilities. At the same time, though, competition could intensify as the number of new entrants increases and as previously closed markets, such as Japan, Mexico, and Saudi Arabia, open up. For readers tracking liberalization trends, see electricity deregulation resources to understand how policy shifts reshape market entry dynamics.  We have developed a model that estimates the value pools available to all players in the utility sector, including power generation, networks, renewables, and downstream products and services (for insights generated by the model and not addressed in the main text, see sidebar below, “Other insights from our model”). For the Asia–Pacific region, China, Europe, and the United States, we estimate that power value pools will increase more than 4 percent a year to 2025. That adds up to an overall increase of €235 billion between 2015 and 2025 (Exhibit 3).

We have developed a model that estimates the value pools available to all players in the utility sector, including power generation, networks, renewables, and downstream products and services (for insights generated by the model and not addressed in the main text, see sidebar below, “Other insights from our model”). For the Asia–Pacific region, China, Europe, and the United States, we estimate that power value pools will increase more than 4 percent a year to 2025. That adds up to an overall increase of €235 billion between 2015 and 2025 (Exhibit 3).

In this article, we explore how the industry is likely to change and then suggest what companies could do to adapt.

Understanding the future: Industry implications

For the future to be different, and better, more of the same is not likely to be an effective strategy. Conditions are changing fundamentally, and fast. Utilities, then, must also change—more speedily and more skillfully than many have proved capable of.

To negotiate this territory, it is useful to have a sense of the trends that are likely to shape the sector. Here are five important ones.

The revenue model for all generation technologies will converge to long-term contracts. Volatility will decrease, but profit margins will not necessarily increase. Over the past five years, overcapacity and low wholesale prices in mature power markets led to severe pressure, and in some cases, market collapse, in purely merchant power generation. The amount of impairments on thermal-generation assets in Europe alone reached €12 billion in 2015. New generation capacity will be difficult to finance under a pure merchant revenue model, in which prices are set by the variable cost of the marginal technology. The recent bloodbath of merchant generation, greater regulatory risk, and the growth of renewable-energy sources, which have zero marginal cost, mean that future prices are uncertain. Long-term fixed prices, either via power purchase agreements or capacity mechanisms, are the most likely new revenue models. In fact, the share of new generation capacity carrying full-price risk has already declined, and we believe it will continue to do so.

However, reduced top-line volatility will not necessarily translate to greater bottom-line results. Most of the projected increase in value pools to 2025 comes from new capacity coming online. The new contracts are awarded after competitive reverse auctions, open to all kinds of competitors. This is likely to continue to drive down the price of winning bids and therefore returns. We have already seen the impact on new renewable capacity. If prices converge further and faster due to greater competition, the pace of technology cost improvement might not be fast enough to offset radically lower revenues. Returns will therefore continue to be under pressure. Some research indicates that the return on equity of large listed clean-energy companies has deteriorated over the past five years.

Transmission and distribution players have a major growth opportunity—and also face major challenges. In the decade to 2025, according to the IEA’s World Energy Outlook, global investments in T&D will approach $3.0 trillion, much more than in fossil generation ($1.1 trillion). This represents a major growth opportunity. In addition, electricity-distribution networks offer interesting synergies with high-speed telecommunications infrastructure, such as fiber to the home and 5G networks. This is already occurring in some European markets. Yet project pipelines can be slowed by costly interconnection delays that compound capex and scheduling risk.

However, there are challenges. First, over the past decade regulation has been benevolent to most T&D players. The spread between financing costs and regulated returns has widened, as the former have collapsed and the latter have been generally flat. However, regional differences remain, as observed for instance in some European countries. In addition, regulation of T&D has not been as effective as in generation with respect to aligning performance to best practices. A McKinsey benchmarking of power-distribution costs in five regions (Australia, Eastern Europe, Latin America, Southeast Asia, and Western Europe) found that the best performers can serve a single point of consumption at a quarter of the cost of the worst. Even in Western Europe, which has efficient players, the gap between the best and the average is almost 100 percent (Exhibit 4).  There are at least two questions: When will policy makers raise their expectations of network operators to provide lower costs and better reliability and safety? And how will regulators address the impact of distributed generation on the grid? In many jurisdictions, contingency planning now highlights critical energy storage as a tool for resiliency and peak support.

There are at least two questions: When will policy makers raise their expectations of network operators to provide lower costs and better reliability and safety? And how will regulators address the impact of distributed generation on the grid? In many jurisdictions, contingency planning now highlights critical energy storage as a tool for resiliency and peak support.

Finally, new energy developments are introducing more complexity: from one-way to bidirectional energy flows, from centralized to decentralized production, and from a centralized to a localized approach to circuits. This will require the adoption of sophisticated software and hardware grid-modernization capabilities. To ground these changes in technical context, consult electric power systems fundamentals for an overview of grid architecture and operation.

From a global standpoint, retail competition is still limited, and where it does exist, profit margins for suppliers have been thin. Long-term profitability in pure commodity retail will be very challenging; retail of other services and products could be profitable, although it is still unproven and will take time.

There are therefore different ways to pursue profitability. For nonresidential segments, a pure commodity play will not be sufficient and suppliers shall seek higher gross margins, for example, by offering new products and services to their existing customers, thus gaining share of wallet. For residential segments, profitability is at risk due to the combination of new competition and regulatory pressure to lower costs to consumers. Suppliers can focus on the bottom line to achieve cost-to-serve levels of €10 per customer or less. Advanced analytics applications for churn prevention and credit management, and the digitization of core user and internal processes, will play a major role.

If margins become unsustainable, retailers might be forced back to a regulated or quasi-regulated business model.

Growth from new businesses or from downstream are unlikely to transform into profits for utilities in the short term. The adoption of distributed technologies and new services has been slower than expected in many markets; only a handful of American states, for example, have reached 2,000 megawatts or more of installed solar capacity or 150 megawatts of storage. Power companies are finding it difficult to extract value from these technologies for three reasons. First, increasing deployment depends to a significant degree on supportive regulation, such as incentives, tax rebates, and favorable rate structures with regard to grid access and energy compensation. Second, providers are struggling to find a sustainable operating model, given high customer-acquisition costs and the number of potential services. Third, there is strong competition from players with diverse backgrounds and skills, including equipment manufacturers, digital companies, telecoms, and start-ups. Even so, scaling programs in several markets are documenting growth in utility-scale energy storage that may alter peak management strategies.

Accordingly, power companies that are considering major investments in distributed generation and new services need to accept that this is a long-term proposition. They should also think about where they have a competitive advantage and how to extend their value proposition along the retail chain.

Interest rates and regulation will be instrumental much more than in the past. In the long term, market forces in large part will determine who wins or loses. The most efficient players will win the capacity auctions and thrive in T&D and retail. That said, interest rates and regulation dynamics will drive industry changes.

In many mature markets, interest rates are low and could therefore be poised to rise. This has several implications. First, it raises the price of new-build capacity, which may destroy the economics of some new projects. Second, it could squeeze margins in regulated networks where remunerated weighted average cost of capital may not be allowed to increase. Third, it lowers attractiveness of energy assets for financial players once excess liquidity can be deployed at similar returns on alternative asset classes, such as treasury bonds.

Regarding regulation, governments can shape the generation mix by choosing which technologies get long-term fixed-price contracts. Similarly, decisions on the end-user tariff structure will determine the scale of downstream opportunities, and regulation will frame the retail environment.

How utilities can prosper

Utilities are facing another decade of massive change, characterized by both substantial risks and considerable opportunities. To convert growth in industry volumes into growth in profits, there are four principles for success.

Get scale. Digitization, industry convergence, market liberalization, and new entrants mean that the barriers to entry are lower than ever. In this context, scale becomes a competitive advantage. Renewables and retail, with their fixed-cost structure, are two areas where scale and competitiveness go hand in hand. In T&D, too, scale will increasingly matter, because regulators will become more demanding with respect to efficiency, and infrastructure ownership will be auctioned off. But scale will mean different things for different players. Only a few companies can become genuinely global, for example. For others, local or regional leadership may be enough to create competitive advantage. In order to get scale, utilities will have to review their capital deployment and be ready to realize significant divestments. Consolidation may be another approach.

Eventually, geographic diversification might become a better option to get scale versus vertical integration, to hedge regulatory risks.

Embrace new technologies. Making good economic use of technology will be important in determining winners and losers, particularly in networks. Applications of advanced analytics to asset management could mean major improvements in cost effectiveness in operations; there is a sizeable efficiency potential to capture via technology. Utilities can strengthen these efforts by applying smart grid data analytics to prioritize investments and reduce failure risk. In fact, this has already happened: we have seen 15 to 25 percent maintenance and replacement cost savings for transformers and circuit breakers and 10 to 20 percent maintenance and replacement cost savings for overhead lines and underground cables. Complementary programs in transformer condition monitoring can sustain these gains through proactive diagnostics and lifecycle planning. Utilities should adopt similar technologies as soon as possible, because they could become mainstream in just a few years.

Focus on regulatory management. In the past, the large share of merchant revenues and profits required utilities to understand future commodity prices. In the future, the dominance of top-down regulation means that anticipating regulation, and possibly helping to shape it, will become the name of the game. Effective regulatory strategy means asking broad questions: What is the cheapest supply mix? Are tariffs and incentives sustainable and fair? It will also be essential to communicate with key stakeholders. Effective regulatory management, then, will be a priority and will require developing new capabilities, such as active institutional advocacy.

Explore adjacencies. The utility industry has never faced so many big disruptions at once. A corollary, then, is that this is a good time to launch new business models. For example, developers might decide to sell an increasing share of ownership to financial players that can offer a lower cost of capital. This is already happening in the renewables sector, and could extend to infrastructure. In another example, T&D players might decide to expand their role within the telecom infrastructure, on the basis of operational synergies. To gain a material share of the value pool coming from the electrification of transportation and new downstream opportunities, utilities might also want to consider new fields, such as insurance and consumer credit. So far, it has to be said, little of this is happening.

The utility industry is entering a period of uncertainty mixed with possibility—of value waiting to be captured, and considerable competition for it. To prosper, utilities must act decisively or face significant and possibly existential risks.

Tiziano Bruno is an associate partner in McKinsey’s Milan office, David Frankel is a partner in the Los Angeles office, Sébastien Léger is a partner in the Paris office, and Antonio Volpin is a senior partner in the Singapore office.

Related Articles

Sign Up for Electricity Forum’s Smart Grid Newsletter

Stay informed with our FREE Smart Grid Newsletter — get the latest news, breakthrough technologies, and expert insights, delivered straight to your inbox.

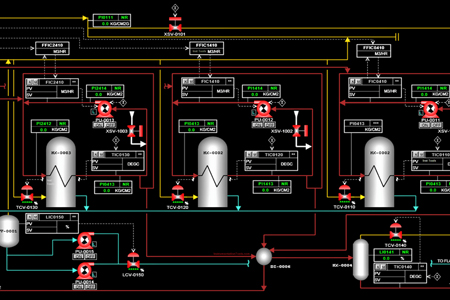

SCADA Architecture

SCADA architecture defines how supervisory control and data acquisition systems are structured across field devices, control servers, and operator interfaces to ensure efficient monitoring, automation, and communication across electrical and industrial utility networks.

What is SCADA Architecture?

SCADA Architecture refers to the layered structure of hardware and software that enables data collection, control, and monitoring in real-time utility operations.

✅ Clearly separates field, control, and user interface layers

✅ Supports scalable and distributed system integration

✅ Enhances real-time visibility, reliability, and fault response

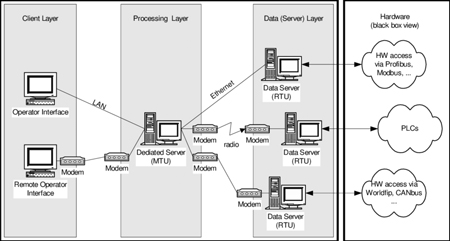

SCADA Architecture – System Design

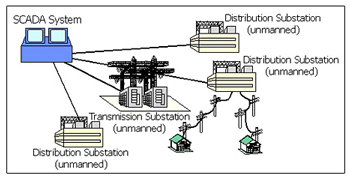

Supervisory control and data acquisition (SCADA) architecture forms the structural backbone of modern industrial automation. It connects field-level devices with centralized software systems to control and monitor processes across wide geographic areas. A robust SCADA design framework ensures reliable data acquisitions, timely system responses, and actionable visibility into remote operations.

SCADA architecture refers to the design and layout of components that enable real-time supervisory control and data acquisition. It includes the physical devices, software platforms, communication networks, and user interfaces that work together to collect data and execute control actions.

This architecture is critical to electrical utilities, water systems, oil and gas pipelines, and other sectors where infrastructure must be controlled from a central location.

-

Organizes sensors, controllers, and software into defined system layers

-

Enables automation and human oversight across remote sites

-

Integrates field data into centralized SCADA software for decision-making

If you want more information about What is SCADA, read the full article.

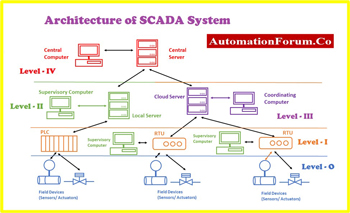

Core Layers of SCADA Architecture

A typical supervisory control design includes four primary functional layers: field instrumentation, control equipment, communication networks, and supervisory software. Each plays a role in the seamless operation of the entire system.

At the field level, sensors measure process variables like voltage, temperature, or flow. These readings are transmitted to remote terminal units (RTUs) or programmable logic controllers (PLCs) for processing. These control devices perform localized automation and send data upstream.

-

Sensors: Capture physical values (e.g., voltage, pressure, flow)

-

PLCs and RTUs: Execute control logic and transmit data

-

Control equipment: Responds to automated or manual operator commands

This structure ensures that real-world operations are constantly observed, interpreted, and acted upon as needed. Read How Does SCADA Work, for a complete description of how this technology is used.

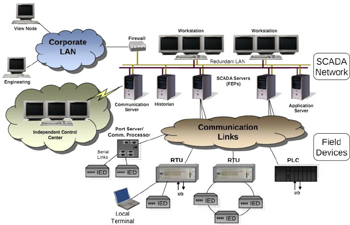

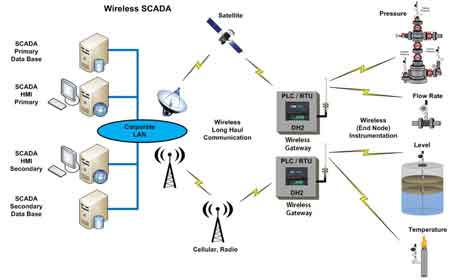

Communication and Data Flow

The effectiveness of SCADA design framework relies heavily on the communication network that links all devices. This network carries data from remote sites to central control rooms using secure, often redundant communication protocols.

Common standards such as Modbus, DNP3, and IEC 60870 ensure data integrity and compatibility across systems. Both wired (Ethernet, fiber) and wireless (radio, cellular) technologies may be used.

-

Protocols: Enable interoperability between diverse equipment

-

Networks: Ensure real-time connectivity across long distances

-

Cybersecurity: Protects control and data acquisition pathways from intrusion

Reliable communication is essential not only for remote control but also for storing and retrieving historical data, which supports trend analysis and maintenance planning.

SCADA Software and User Interfaces

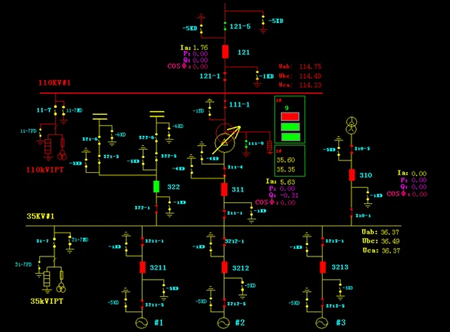

Once data reaches the central system, SCADA software processes it. This software layer applies logic, triggers alarms, and archives operational records. Operators interact with the system through human machine interface (HMI) screens that provide real-time visualizations of process conditions.

A well-designed user interface enhances safety and decision-making. It displays alarms, trending data, equipment status, and control options in an intuitive layout.

-

SCADA software: Executes automation logic, stores data, manages alarms

-

HMI: Allows operators to monitor and control systems through graphic displays

-

User interfaces: Provide access to live and historical data

Operators can manually adjust setpoints, acknowledge alerts, or trigger system overrides as needed.

Types of SCADA System Architecture

Over the years, several architectural models have evolved to meet growing industrial needs. Each model represents a step toward greater connectivity, reliability, and scalability.

-

Monolithic SCADA systems – Early centralized systems with limited external communication. Rarely used today.

-

Distributed systems – Introduced modularity by spreading tasks across separate computers. Increased reliability.

-

Networked SCADA systems – Today’s standard, connecting all components through integrated networks.

-

Modern SCADA systems – Incorporate cloud platforms, mobile access, and advanced analytics for greater flexibility.

These types of SCADA system architectures reflect the increasing demand for system integration, remote access, and real-time automation.

Applications in Electrical Automation

In electrical engineering, SCADA system layout plays a central role in industrial automation and grid management. It enables power utilities to control transmission lines, substations, and switchgear from a distance.

Control equipment, such as circuit breakers and transformers, is operated via PLCs and monitored through HMI terminals. Data is logged for performance evaluation, fault detection, and preventive maintenance.

-

Coordinates voltage regulation and load balancing

-

Reduces manual intervention and improves response time

-

Ensures safe, reliable operation across high-voltage infrastructure

As smart grid initiatives grow, SCADA serves as the command center for distributed energy resources and grid-wide optimization.

The Role of System Integrators

Designing and deploying a modern SCADA framework requires the expertise of system integrators. These professionals configure communication links, program PLCs, set up RTUs, and develop custom HMI layouts tailored to the application.

They also ensure that all components—from field sensors to control software—function together as a cohesive system.

-

Build and program automation systems

-

Configure user interfaces and alarm management

-

Optimize system architecture for reliability and scalability

Their work is essential in creating solutions that meet industry-specific standards for safety and performance.

SCADA system layout is more than just a technical blueprint—it’s the operational foundation for critical infrastructure. By combining programmable logic controllers and remote terminal units, reliable networks, powerful SCADA software, and intuitive HMIs, this architecture enables seamless control and data acquisition across diverse applications.

It supports real-time decisions, minimizes downtime, and offers centralized visibility for complex systems. As demands grow and technologies evolve, supervisory system design remains a cornerstone of connected, intelligent, and automated operations.

Related Articles

SCADA Cybersecurity

SCADA cybersecurity protects industrial control systems from cyber threats, ensuring safe, reliable grid operations. It prevents unauthorized access, malware, and data breaches in energy, water, and utility infrastructures.

What is SCADA Cybersecurity?

SCADA cybersecurity focuses on defending Supervisory Control and Data Acquisition systems against cyber risks. It safeguards operational continuity and public safety in critical infrastructure.

✅ Protects SCADA systems from cyberattacks and unauthorized access

✅ Ensures reliability of electrical grids, water treatment, and gas networks

✅ Prevents malware, ransomware, and data breaches in OT/ICS networks

The Growing Importance of Industrial Security

As critical infrastructure grows more connected, protecting supervisory control and data systems from cyber threats becomes essential. Once isolated, these control environments are now digitally linked to corporate networks, exposing them to sophisticated cyber attacks. SCADA cybersecurity isn’t just a technical concern—it’s a fundamental requirement for safety and operational continuity. If you're new to the subject, start with this in-depth introduction that answers the fundamental question: what is SCADA?

Control and data acquisition systems enable operators to monitor and control complex physical processes remotely. But the same capabilities that allow for remote control, automation, and real-time diagnostics can also be exploited by adversaries. Without proper protections, attackers can gain access to core systems and cause physical or financial damage.

Inherent Weaknesses in System Architecture

Legacy systems were never designed for cybersecurity. Many data acquisition SCADA systems in use today still rely on outdated hardware and software with little to no ability to authenticate users or encrypt communications. These environments operate under assumptions of physical isolation, leaving them highly vulnerable once network boundaries are crossed.

Cyber threats take many forms. Some rely on remote access exploits or phishing to infiltrate a system, while others directly target programmable logic controllers (PLCs), sensors, and engineering workstations. Even attacks that appear subtle—like falsifying readouts while processes are sabotaged—can have widespread effects. One famous historical case demonstrated how attackers could manipulate control code while masking the changes from operators, highlighting how difficult such intrusions can be to detect. For a clear explanation of core components and data flow in control systems, see our guide on how does SCADA work.

Limiting Risk Through Segmentation and Visibility

One of the most effective strategies for defense is strong network segmentation. Separating critical control systems from corporate IT networks limits the damage an attacker can do once inside.

Security teams should:

-

Create isolated zones for PLCs, HMIs, and historian servers

-

Use secure gateways for data acquisition systems

-

Prevent direct links between external networks and core SCADA networks

-

Maintain updated network diagrams showing all connected devices and communication flows

These practices reduce the attack surface and enable focused monitoring of each zone.

Managing Remote Access and Privileges

While remote access enables operators and engineers to perform diagnostics or updates without being on site, it’s also a prime entry point for attackers. Secure remote access must be enforced through encrypted VPNs, jump servers, and multi-factor authentication. All remote sessions should be logged and monitored for anomalies.

Access controls should follow the principle of least privilege. Only authorized personnel should access sensitive systems, and only with the specific permissions they require. Eliminating shared credentials and using role-based access greatly improves accountability and reduces risk. To understand the layered structure of control environments, including PLCs, HMIs, and communication links, explore our article on SCADA architecture.

Detecting Threats in Real Time

An intrusion detection system (IDS) tailored to industrial control environments can catch threats that perimeter defences miss. These systems inspect ICS-specific protocols like Modbus and DNP3 for unusual activity, flagging commands that deviate from expected patterns.

By analyzing traffic within each control segment, the IDS adds a valuable layer of internal defence, especially in systems where legacy components cannot be easily patched or upgraded. Discover how control systems operate in utility substations and how they’re evolving with grid modernization in our substation SCADA overview.

Hardening the System Against Exploits

Given the persistence of legacy infrastructure, hardening becomes a practical necessity. This includes:

-

Disabling unused ports and services

-

Replacing default factory credentials with unique, secure passwords

-

Installing vendor firmware updates where possible

-

Using unidirectional gateways to prevent external write access

For systems that cannot be fully updated, isolating them from wider networks and applying strict firewall rules helps minimize exposure. For insight into how operators oversee system performance and detect anomalies in real time, read about SCADA monitoring strategies.

Encryption and Compliance Standards

Communications between control components should be encrypted wherever possible. Protocols like Modbus and DNP3 can be encapsulated within TLS or tunneled through secure gateways to ensure confidentiality and integrity.

Aligning your cybersecurity program with established standards—such as ISA/IEC‑62443, NIST SP‑800‑82, and NERC CIP—provides a tested framework for managing risk. These standards address everything from device-level hardening to enterprise-wide governance.

Training, Testing, and Continuous Improvement

Technology alone cannot guarantee cybersecurity. Personnel must be trained to understand potential threats, recognize suspicious behavior, and follow secure procedures when configuring or updating systems. Security awareness should be embedded in every role that interacts with control technology.

It’s also important to test your defences regularly. Simulated attacks, vulnerability scans, and red team exercises reveal blind spots. These insights guide improvements in everything from incident response to patching strategy. Learn how different platforms and protocols work together across operational networks by exploring SCADA integration techniques.

A Secure Path Forward

SCADA cybersecurity is about more than firewalls and passwords. It requires a holistic view of how control systems interact with the outside world and how attackers might exploit those pathways. From access controls and segmentation to training and monitoring, each layer adds strength to the whole.

By combining proactive design, real-time visibility, and disciplined process management, organizations can stay ahead of potential threats. In a landscape where attackers are increasingly targeting industrial systems, resilience isn’t optional—it’s operational survival.

Related Articles

_1752206400.jpg)

What is SCADA?

SCADA is a utility-grade system that enables real-time grid monitoring, remote control, fault detection, and substation automation. It improves electric utility reliability, safety, and performance through centralized supervision and smart data collection.

What is SCADA?

SCADA (Supervisory Control and Data Acquisition) :

✅ Monitors and controls the electric grid in real time using data from substations, breakers, transformers, and field sensors.

✅ Enables remote operations so utilities can issue commands, respond to alarms, and reconfigure the system without on-site intervention.

✅ Improves reliability, safety, and efficiency by automating processes, logging historical data, and supporting predictive analytics.

Key Functions of SCADA in Utilities

In today’s power systems, real-time control, automation, and visibility are not optional—they’re essential. SCADA systems make this possible. For electric utilities, SCADA serves as the digital nervous system, connecting control centers with field equipment spread across substations, switchyards, feeders, and beyond. It turns dispersed infrastructure into a responsive, manageable network.

Rather than being a single tool or software, SCADA is a layered ecosystem. It integrates sensors, control logic, data communication, human-machine interfaces (HMI), and centralized supervision. This orchestration allows utility operators to make informed decisions, respond instantly to failures, and maintain system stability at all times. See How Does SCADA Work, for a complete description of how this technology is used.

At the heart of every SCADA system is a set of operational capabilities that allow it to fulfill its core mission: monitor and control the power grid effectively. These functions go beyond passive observation—they enable dynamic responses, predictive planning, and precise execution. They are what make SCADA systems active participants in grid operations, not just silent observers.

-

Real-Time Monitoring: Continuously gathers data such as voltage, current, frequency, breaker position, and transformer temperatures across the network.

-

Remote Control: Allows operators to open/close breakers, switch circuits, change setpoints, and reset alarms from the control center.

-

Alarm Management: Detects abnormal or unsafe conditions and triggers alerts for immediate response.

-

Event Logging and Data Archiving: Records time-stamped operational data and events for analysis, troubleshooting, and compliance.

-

System Diagnostics: Detects and diagnoses communication failures, equipment faults, or sensor malfunctions to support rapid maintenance.

SCADA systems also play a vital role in industrial automation by connecting control equipment across large utility and manufacturing environments. These systems rely on both local control at field sites and centralized coordination via remote terminal units (RTUs). Modern SCADA software integrates seamlessly with user interfaces to provide real-time data visualization and control, enabling operators to manage complex processes efficiently. Through wireless communication, SCADA platforms can transmit data between remote assets and control centers, ensuring reliability, scalability, and rapid response in mission-critical applications.

SCADA System Components and Their Functions

| Component | Description | Function in SCADA System |

|---|---|---|

| Control Equipment | Devices such as breakers, valves, switches, and relays | Executes commands received from RTUs or PLCs |

| Industrial Automation | Use of control systems for industrial processes | Improves operational efficiency and reduces manual intervention |

| Local Control | On-site decision-making via PLCs or embedded logic | Enables rapid response without relying on central systems |

| Remote Terminal Units (RTUs) | Field devices that collect data and send control signals to equipment | Interface between field sensors/actuators and SCADA master station |

| SCADA Software | Centralized applications for monitoring, command execution, and logging | Manages data visualization, alarms, trending, and control logic |

| User Interfaces | HMIs (Human-Machine Interfaces) and dashboards | Allow operators to interact with system data and issue commands |

| Wireless Communication | Radio, cellular, or satellite links between remote sites and control centers | Enables real-time remote control and data transmission |

SCADA Architecture Overview

Understanding SCADA means understanding its structure. SCADA architecture isn’t just about connecting devices; it’s about building a system that supports scalability, cybersecurity, and seamless integration across operational tiers. Each component plays a distinct role, contributing to a chain of data flow and control that supports mission-critical decisions.

-

Field Devices (Level 0): Sensors and actuators gather raw process data and execute mechanical actions such as opening a breaker or adjusting voltage tap changers.

-

Control Devices (Level 1): RTUs and PLCs collect, preprocess, and transmit data from field devices. RTUs are optimized for remote or harsh environments, while PLCs are more common in plant-based automation.

-

Supervisory Systems (Level 2): The SCADA server, HMI, and master station run applications that collect data, visualize grid conditions, issue control commands, and manage alarms.

-

Enterprise Systems (Level 3): Often includes integration with Historian databases, outage management systems (OMS), GIS, and other IT/OT platforms for long-term analysis and decision-making.

Benefits of SCADA in the Electric Power Industry

The deployment of SCADA transforms how utilities manage both routine operations and emergency conditions. Beyond the technology, the real value lies in the measurable improvements to grid reliability, safety, and cost-effectiveness. These systems are not only reactive—they are predictive, proactive, and increasingly intelligent.

-

Increased Reliability: Continuous monitoring ensures faults are detected early and power can be rerouted or isolated before causing widespread outages.

-

Operational Efficiency: Reduces the need for manual intervention and site visits, especially for remote substations or feeders.

-

Improved Safety: Enables technicians to interact with high-voltage systems remotely, lowering exposure risk.

-

Data-Driven Planning: Collected historical data feeds asset management, load forecasting, and predictive maintenance models.

-

Regulatory Compliance: Logging and reporting features help satisfy regulatory and auditing requirements.

Utility-Specific SCADA Use Cases

While SCADA has broad applications, it takes on specific roles in utility environments based on network topology, regulatory demands, and system goals. Its flexibility allows utilities to tailor the system to their operational needs, whether for outage response, distributed energy integration, or smart substation control.

-

Substation Automation: Monitor and control power transformers, circuit breakers, battery banks, and environmental systems.

-

Distribution Automation (DA): Use FLISR (Fault Location, Isolation, and Service Restoration) to minimize outage durations and reroute power in real time.

-

Load Management: Implement demand response strategies, peak shaving, and load forecasting based on real-time usage data.

-

Renewable Energy Integration: Monitor variable generation from solar and wind farms, ensuring safe grid interconnection and voltage control.

-

Black Start and Emergency Response: Provide visibility and control during total or partial grid outages, supporting fast recovery procedures.

Frequently Asked Questions - What is SCADA?

How is SCADA different from other utility control systems like EMS or DCS?

SCADA is designed for monitoring and controlling distributed field assets over wide geographic areas, such as substations and feeders. EMS (Energy Management Systems) are used at the transmission level for power flow modelling and balancing, while DCS (Distributed Control Systems) are typically confined to single-site process control, like in power plants or water treatment facilities.

Can SCADA systems be used with renewable energy sources like solar and wind?

Modern SCADA systems are essential for integrating renewable energy. They monitor generation output, voltage levels, and weather conditions, and help utilities manage intermittency, balance loads, and protect the grid from fluctuations caused by variable power sources.

Is SCADA secure from cyberattacks?

While SCADA systems are increasingly exposed to cybersecurity threats, best practices like network segmentation, secure protocols (e.g., DNP3-SA, IEC 62351), role-based access control, and regular vulnerability assessments can significantly reduce risk. Many utilities also deploy firewalls, VPNs, and intrusion detection systems to secure SCADA communications.

Related Articles

IEEE Transactions on Smart Grid

IEEE Transactions on Smart Grid is a peer-reviewed journal publishing research on power systems, smart grid technologies, renewable energy integration, electrical network modernization, and cybersecurity, advancing innovation for sustainable electricity.

What are the IEEE Transactions on Smart Grid?

IEEE Transactions on Smart Grid is a leading academic journal covering advanced research in power systems, communication technologies, and renewable energy integration.

✅ Publishes peer-reviewed studies on smart grid technologies

✅ Supports innovation in energy efficiency and reliability

✅ Bridges academia, utilities, and network operators worldwide

Comprehensive Overview

The IEEE Transactions on Smart Grid is a leading international journal dedicated to advancing knowledge in smart grid infrastructure, network intelligence, and emerging energy systems. Powered by the Institute of Electrical and Electronics Engineers (IEEE), this publication plays a pivotal role in bridging the global gap between traditional power delivery systems and modern, adaptive energy networks.

Publishing Scope and Research Areas

The journal focuses on the technical, practical, and strategic aspects of the smart grid. Topics frequently covered include smart grid communication, grid automation, distributed energy resources, cyber-physical systems, network resilience, and integration of renewable energy sources.

With a multidisciplinary approach, the publication attracts research from specialists in electrical engineering, computer science, communications, management, and energy economics. Articles may explore areas such as demand response, advanced metering, network security, substation automation, real-time monitoring, and the role of energy storage on a grid scale.

Peer Review and Academic Rigor

As a peer-reviewed journal, it maintains high academic standards to ensure the excellence and relevance of its content. Submissions are evaluated by experts for technical accuracy, originality, practical significance, and potential impact on the field. This process fosters thought leadership and innovation across academia, utilities, and industry.

The journal features regular issues as well as special issues dedicated to emerging topics, such as artificial intelligence in network management, electric vehicle integration, and smart charging infrastructure, including the work presented by the NREL's Electric Vehicle Infrastructure Projection Tool.

Real-World Impact and Applications

Contributions often present results from testbeds, pilot projects, and field deployments. Examples include case studies of Duke Energy Florida’s smart-thinking grid, which improved hurricane response and recovery. By documenting best practices and lessons learned, the journal empowers global utilities and policy makers to adopt proven methods for improving electrical stability, reliability, and efficiency.

Furthermore, the journal plays a crucial role in fostering standardization and interoperability across different smart grid platforms, advancing both research and implementation of technologies such as smart substations and grid monitoring using SCADA.

Global Collaboration and Forward-Looking Trends

The IEEE Transactions on Smart Grid is recognized worldwide, attracting contributions from leading experts and organizations actively involved in the deployment of smart grids. It supports collaboration through information sharing, offering a platform to discuss international perspectives, such as the Egypt-Huawei partnership for grid transformation and large-scale renewable integration efforts in countries like India and Ireland.

Looking forward, IEEE continues to spotlight innovations that are transforming the world’s electrical infrastructure. The journal tracks advancements in cyber-physical security as power networks face increasing attacks, in-depth studies on microgrid economics as adoption grows, and strategies to overcome barriers to the integration of 100% renewable energy, as seen in the U.S. grid transformation discussion.

Why It Matters

Staying abreast of research published in IEEE is crucial for professionals designing, operating, or regulating modern energy systems. The journal's influence extends to utility engineers, academic researchers, policy makers, and technology providers worldwide. By presenting validated research, emerging trends, and practical solutions, the publication enables its readers to drive progress towards a more sustainable, resilient, and efficient future network.

Accessing the Journal

Subscribers can access current and archived issues through the IEEE Xplore Digital Library. Many universities and institutions provide access to students and staff. Individual articles may be purchased or accessed via interlibrary loan for non-subscribers.

In summary, IEEE Transactions on Smart Grid remains an essential resource for anyone interested in the evolution of global electrical infrastructure, guiding the technological and policy innovations that will define the power networks of tomorrow.

Related Articles

Substation SCADA

Substation SCADA provides real-time monitoring, control, and automation for substations using RTUs, HMIs, and protocols like IEC 61850 and DNP3, improving grid reliability, fault detection, and operational efficiency.

What is Substation SCADA?

Substation SCADA refers to a digital control and data acquisition system that enhances substation performance, protection, and operational visibility.

✅ Real-time monitoring, alarms, and automated control

✅ Uses IEC 61850, DNP3, RTUs, and HMIs for interoperability

✅ Improves fault detection, response time, and uptime

Substation SCADA and Intelligent Automation

In a modern electrical grid, where reliability, speed, and remote control are essential, substation SCADA systems form the backbone of intelligent automation and control. These systems integrate advanced hardware, fibre-based networks, and standardized protocols to deliver real-time insights, enable proactive fault detection, and optimize electrical power distribution. A well-designed substation SCADA implementation is more than a control system—it is a comprehensive digital platform for grid management. For a broader overview of SCADA applications across the electrical grid, visit our article on what is SCADA and how it's used.

Why Substation SCADA Matters for Modern Power Grids

Modern electrical grids are more complex than ever, with fluctuating demand, renewable energy integration, and a growing need for remote management. Substation SCADA systems give utilities the ability to monitor and control operations in real time, ensuring that equipment failures are detected and addressed before they cause widespread outages. By enabling proactive maintenance, these systems reduce downtime, lower operating costs, and allow faster recovery from faults—critical advantages in an era where even brief service interruptions can impact thousands of customers and significant revenue.

Core Benefits of Substation SCADA Systems

-

Faster fault isolation — IEC 61850 peer-to-peer messaging coordinates protective relays in milliseconds, minimizing outage duration.

-

Reduced operational costs — Remote monitoring and control reduce the need for frequent site visits and manual inspections.

-

Improved reliability — Redundant communication paths and automated fault detection keep the grid stable under stress.

-

Enhanced security — Edge computing, VPNs, and network segmentation guard against cyber threats while maintaining operational performance.

-

Optimized asset life — Continuous condition monitoring helps schedule maintenance before failures occur, extending equipment lifespan.

The Evolution of Substation SCADA Technology

Early SCADA systems in substations were limited to basic telemetry and manual control, relying on analog signals and proprietary protocols. The shift to digital platforms introduced standardized communication, greater interoperability, and richer data visualization. Today’s systems are fully integrated into smart grid architectures, using IEC 61850 for high-speed data exchange, real-time analytics, and automated decision-making. Emerging trends—such as AI-driven fault prediction, distributed energy resource (DER) management, and advanced cybersecurity—are transforming SCADA into a central intelligence hub that not only monitors the grid but actively optimizes its performance in a dynamic energy landscape.

Substation SCADA System Overview

| Component | Function | Technology/Standard | Benefit |

|---|---|---|---|

| Remote Terminal Unit (RTU) | Collects data from field devices and transmits it to SCADA master | DNP3, Modbus, IEC 60870-5 | Enables remote data collection and control |

| Intelligent Electronic Device (IED) | Executes protection and automation logic at the bay level | IEC 61850, GOOSE, Sampled Values | Provides fast fault isolation and local control |

| Human-Machine Interface (HMI) | Visualizes system status, alarms, and trends for operators | SCADA Master Station | Enhances situational awareness and decision-making |

| Communication Network | Transfers real-time data and control signals | Fiber Optic Ethernet, Redundant Ring | Ensures fast and secure communication |

| SCADA Master Station | Central control hub for data processing, command execution, and logging | Supervisory Control and Data Acquisition | Enables remote operation and data integration |

| Data Historian | Stores time-stamped data for analysis and reporting | SQL, NoSQL, or proprietary DB systems | Supports trend analysis and compliance |

| Cybersecurity Layer | Protects communication and device access | VPN, Firewalls, IEC 62351, Authentication | Prevents unauthorized access and cyber threats |

| Phasor Measurement Unit (PMU) | Captures time-synchronized electrical waveforms for WAMS | IEEE C37.118, IEEE 1588 | Enables wide-area situational monitoring |

| Remote Access Gateway | Enables secure access from control centers or field locations | VPN, HTTPS, 2FA | Allows flexible and secure substation management |

Key Components and Architecture

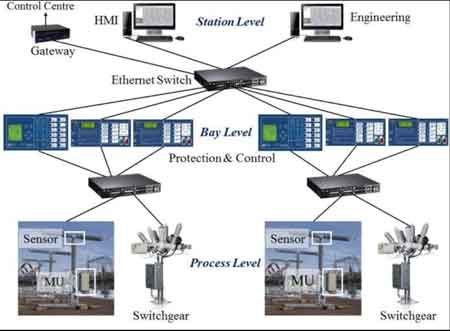

Substation SCADA is an automated system that manages monitoring and control of substation equipment via a structured, three-tier architecture:

-

Process Level: Current and voltage transformers, merging units, and sensors gather data from field equipment. Phasor Measurement Units (PMUs) also measure time-synchronized values critical for wide area monitoring.

-

Bay Level: Intelligent Electronic Devices (IEDs) execute local control logic and protection relays to isolate faults within milliseconds.

-

Station Level: Remote terminal units (RTUs) or embedded gateway devices collect data and send it via secure communication protocols to the SCADA master station for centralized management.

Each layer contributes to low-latency operation and ensures that the system can withstand equipment failure through redundancy, including backup RTUs, IEDs, and dual-fibre optic communication rings. To better understand the fundamentals behind substation control, see our article on how does SCADA work.

Human-Machine Interface and Real-Time Operations

The human machine interface (HMI) serves as the operator’s window into the substation. It displays a dynamic single-line diagram with live status of switches, breakers, voltages, and currents. Operators can view historical data through a data historian, manage alarms, and analyze event sequences through replay tools.

Advanced HMIs support custom dashboards, drill-down views of assets, and secure remote access, allowing utilities to operate substations across wide territories with minimal on-site presence.

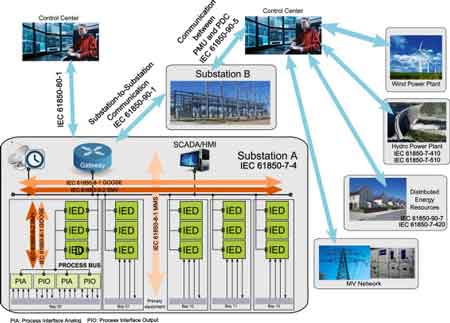

Communication Protocols and Interoperability

Reliable communication is the foundation of substation automation. Modern systems implement a suite of communication protocols such as DNP3, Modbus/TCP, and IEC 60870-5-104, but increasingly rely on the IEC 61850 standard, which supports vendor interoperability, high-speed messaging, and data modelling.

IEC 61850 enables peer-to-peer GOOSE messaging for fast relay coordination, sampled values (SV) for accurate analog data over Ethernet, and MMS for secure station-level communication. These protocols run over industrial fibre optic networks designed with ring or star topologies for fault-tolerant performance.

To ensure deterministic performance, substation devices rely on network time synchronization technologies like IEEE 1588 Precision Time Protocol, which ensures aligned data timestamps across IEDs, PMUs, and historian logs.

Cybersecurity and Edge Protection

As remote access and cloud integration become increasingly common, cybersecurity becomes critical. Modern SCADA architectures utilize encrypted communication channels, firewalls, intrusion detection systems, and OT network segmentation. Virtual Private Networks (VPNs), two-factor authentication (2FA), and firmware hardening further protect substations from unauthorized access.

Edge computing also plays a growing role in securing and streamlining substation functions. By processing data locally, edge devices reduce bandwidth needs, improve response time, and isolate critical operations from cyber threats.

Intelligent Devices and Substation Automation

Substation automation depends on the distributed intelligence of IEDs and merging units. These devices not only respond to protection logic but also automate routine switching, collect asset health data, and manage bay-level operations without constant supervision from the SCADA master.

IEDs communicate using IEC 61850 and interact seamlessly with HMIs, alarm managers, historians, and remote control centers. Integration with Wide Area Measurement Systems (WAMS) using PMUs adds another layer of situational awareness, especially valuable during grid disturbances.

Integration with Smart Grid and DERs

Substation SCADA plays a key role in smart grid evolution. As utilities incorporate distributed energy resources (DERs) like solar, wind, and battery storage, SCADA systems provide real-time data, coordination, and automation and control logic to manage fluctuating inputs and load balancing.

Smart substations are also equipped to support demand response, VRE forecasting, and grid-forming inverter coordination. This flexibility ensures resilience in the face of grid decentralization and enhances long-term asset management capabilities. Learn how communication layers and network design impact performance in our detailed explanation of SCADA architecture.

Event Management, Alarms, and Historian Functions

Real-time and historical visibility is essential for diagnosing faults and optimizing performance. Substation SCADA includes a robust alarm management system that prioritizes events and enables detailed event replay. The data historian captures time-series values for analysis, regulatory reporting, and predictive maintenance.

By analyzing trends, correlating alarms, and reviewing switching sequences, engineers gain deep insights into substation performance and can proactively manage equipment health.

Substation SCADA systems are far more than basic supervisory control and data acquisition platforms—they are critical enablers of modern power system functionality. Built on fibre optic networks, secured with advanced cyber protections, and powered by IEDs and PMUs, these systems offer scalable, real-time monitoring and control solutions for today’s dynamic grid. As substation automation advances, SCADA’s role will continue to evolve, integrating edge analytics, smart grid orchestration, and secure remote operations to support the growing complexity of electrical power infrastructure.

Related Articles

Smart Substation and the Evolving Grid

Smart substation technology uses digital sensors, IEDs, and secure communications to automate protection, monitoring, and control, improving grid reliability, power quality, and DER integration across modern substations.

What is a Smart Substation?

A smart substation is a digitally enabled substation that applies IEC 61850, IEDs, SCADA, and analytics to automate control, protection, and data exchange.

✅ Real-time monitoring, automation, and fault response

✅ Standards-based communications (IEC 61850) for interoperability

✅ Improved reliability, cybersecurity, and DER integration

The Smart Substation and Smart Grid

The power industry is undergoing a profound transformation driven by grid modernization, renewable integration, and increasing demands for resilience and efficiency. At the heart of this evolution lies the smart substation—a next-generation facility equipped with advanced sensors, digital communications, and real-time control technologies. These substations are foundational to the smart grid, serving as critical nodes that enable automated monitoring, faster fault response, and optimized power flow. For a broader look at grid modernization efforts that support smart substation deployment, visit our Smart Grid Overview.

As utilities shift from analog to digital substations, the move generates complex questions about architecture, cybersecurity, return on investment (ROI), and implementation strategy. However, the long-term value of smart substations—through improved reliability, operational efficiency, and grid intelligence—makes them an essential part of the future energy landscape. Explore how Coordinated Automation Schemes enhance system efficiency and reliability within smart substations.

What Defines a Smart Substation?

A smart substation goes beyond traditional functionality by integrating advanced digital technologies that enhance visibility, control, and automation. While conventional substations focus on mechanical protection and simple monitoring, smart substations leverage:

-

IEC 61850-based communication protocols

-

Intelligent Electronic Devices (IEDs)

-

Edge computing platforms

-

Phasor Measurement Units (PMUs)

-

IoT sensors and digital relays

Together, these technologies enable real-time data acquisition, remote control, and adaptive protection schemes, creating a dynamic interface between transmission, distribution, and distributed energy resources (DERs). Learn how Smart Grid Data Analytics enable predictive maintenance and adaptive fault detection at the substation level.

Edge Computing in Smart Substations

One of the core innovations in smart substations is the adoption of edge computing—processing data locally at the substation level rather than sending it all to a centralized control center. This distributed intelligence reduces latency, enhances fault response, and eases the burden on wide-area communication networks.

Edge analytics enable real-time decisions to be made closer to the source of events. For example:

-

Fault detection and isolation can be automated in milliseconds

-

Voltage control and reactive power adjustments can be localized

-

Predictive maintenance can be applied using sensor data from breakers, transformers, and other critical equipment

This shift toward decentralized intelligence supports a more agile and responsive grid, especially as DERs, electric vehicles (EVs), and variable renewables introduce complexity and volatility into power flows.

-

Discover the importance of real-time visibility in substation operations with our page on Smart Grid Monitoring.

AI and Machine Learning in Substation Operations

To manage the growing data volume generated by smart substations, utilities are turning to AI and machine learning tools. These technologies offer the ability to identify patterns, detect anomalies, and optimize system performance across various time scales.

Applications of AI in smart substations include:

-

Predictive maintenance: Using historical data to forecast equipment failure before it happens

-

Fault classification: Automatically distinguishing between transient, permanent, or nuisance faults

-

Dynamic load forecasting: Improving dispatch decisions and reducing peak demand

-

Adaptive protection schemes: Automatically adjusting relay settings based on real-time grid conditions

Machine learning models trained on substation telemetry data can evolve over time, improving accuracy and enabling data-driven decision-making. This reduces the need for manual intervention and allows grid operators to proactively address emerging issues. For insights into how SCADA systems integrate with smart substations, explore our overview of supervisory control and data acquisition.

PMUs and Synchrophasors: Enhancing Situational Awareness

Phasor Measurement Units (PMUs) and their associated data, known as synchrophasors, are another critical component of smart substation functionality. These devices measure electrical waves at high speed with precise time stamps using GPS-synchronized clocks.

PMUs improve situational awareness by:

-

Providing real-time visibility into voltage and current phase angles

-

Supporting wide-area monitoring systems (WAMS)

-

Detecting grid oscillations, frequency deviations, and angular instability

-

Enabling fast response to events like line faults or islanding

By embedding PMUs in smart substations, utilities gain a time-synchronized, wide-area view of grid dynamics, essential for maintaining stability in a system increasingly influenced by fast-changing loads and generation profiles. Understand how Improved Sensor Technology supports smart substations by enabling accurate, real-time equipment diagnostics.

Challenges and Considerations

Despite their benefits, deploying smart substations involves several challenges:

-

High capital costs for retrofitting or building from scratch

-

Integration with legacy systems and analog infrastructure

-

Cybersecurity risks from increased digital exposure

-

The need for staff training in digital technologies and system interoperability

-

Ensuring compatibility with utility-wide data platforms and SCADA/EMS systems

However, the ROI of smart substations often becomes clear over time, as utilities realize gains in reliability, reduced outage durations, streamlined maintenance, and enhanced regulatory compliance. Cybersecurity is vital—see our guide on the DHS-FBI Alert to understand threats to smart substation infrastructure.

Conclusion

Smart substations are a cornerstone of the evolving smart grid, enabling faster, smarter, and more efficient control of the power system. Through technologies such as edge computing, AI and machine learning, and PMU-based situational awareness, they provide the foundation for a responsive, resilient, and data-rich energy network.

As utilities continue to modernize, the implementation of smart substations will not only support immediate operational benefits but also position the grid to handle the challenges of tomorrow—from renewable integration to real-time analytics and autonomous grid operation. Investing in smart substation architecture is not just about upgrading hardware—it's about building the intelligent backbone of the future grid.

Related Articles