Latest Electrical Substations Articles

IEC 61850 Protocol For Substations

IEC 61850 protocol enables fast, standardized communication between intelligent electronic devices (IEDs) in substations. It supports interoperability, real-time data exchange, and remote monitoring, making it vital for smart grid automation and modern power system protection.

What is IEC 61850 Protocol?

✅ Standardized communication for substation automation and control systems

✅ Enables interoperability between IEDs from different vendors

✅ Supports real-time monitoring, protection, and data exchange in smart grids

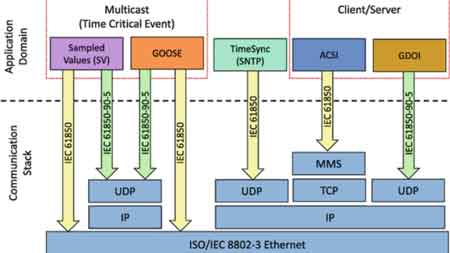

IEC 61850 is a communications protocol developed by the International Electrotechnical Commission (IEC) for substation automation systems. Unlike older legacy protocols that rely on fixed, vendor-specific formats, IEC 61850 uses an object-oriented data interoperability and abstract communication services to create a standardized method for data exchange among IEDs, SCADA system integration, and Human-Machine Interfaces (HMIs).

Its architecture is based on Ethernet and supports both client-server and peer-to-peer communications, making it ideal for smart grid applications that require high-speed, deterministic messaging. Explore how 3D substation design using AutoCAD can streamline planning for IEC 61850-based systems.

The IEC 61850 standard is an international standard defining the communication protocols used for intelligent electronic devices within electrical substations. Developed to support automation, this standard-defining framework enables interoperability and seamless data exchange between devices from different manufacturers. IEC 61850 is an international effort aimed at modernizing substation communications and improving reliability. One of its most innovative features is GOOSE (Generic Object-Oriented Substation Event) messaging, which facilitates high-speed, event-driven communication between devices without the need for a master controller. By standardizing these protocols, IEC 61850 plays a critical role in the development of secure, efficient, and future-ready power systems.

Key Features of the IEC 61850 Standard

-

Interoperability Across Devices

-

IEC 61850 enables seamless integration of equipment from multiple manufacturers by defining common data structures and naming conventions. This interoperability reduces engineering time and ensures long-term system flexibility.

-

-

High-Speed Messaging with GOOSE

-

The protocol includes GOOSE messaging (Generic Object-Oriented Substation Events), which allows IEDs to communicate critical event data in under 4 milliseconds. These peer-to-peer messages operate at the Ethernet layer, making them ideal for protection and control schemes.

-

-

Process Bus and Station Bus Architecture

-

IEC 61850 divides communication into two logical layers:

-

Station Bus: Handles data exchange between IEDs, SCADA, and HMIs using MMS (Manufacturing Message Specification).

-

Process Bus: Replaces traditional copper wiring by transmitting sampled values (SV) and control signals between field equipment and IEDs over Ethernet via Merging Units (MUs).

-

-

-

Scalable Data Modeling

-

The standard uses Logical Nodes and Logical Devices to define all data points in a substation. This object-oriented modeling enables efficient configuration, simplified diagnostics, and faster system deployment.

-

-

Time Synchronization

-

IEC 61850 supports Precision Time Protocol (PTP) to align time-sensitive operations across devices, which is essential for fault analysis, event recording, and system coordination.

-

Benefits of the GOOSE Messaging Protocol

The move toward IEC 61850-based systems brings significant advantages to utility operators and system integrators:

-

Reduced wiring complexity and installation costs

-

Improved protection system response through fast GOOSE messaging

-

Vendor-agnostic system design

-

Future-proofing with support for emerging smart grid technologies

-

Easier integration of renewable energy, energy storage, and microgrids

-

Enhanced cybersecurity through standards such as IEC 62351

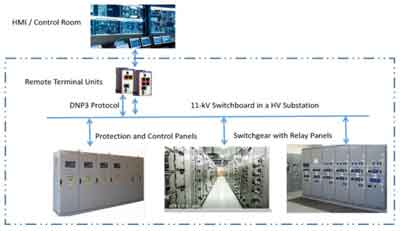

See how RTU and HMI redundancy enhances system reliability within IEC 61850-enabled stations.

IEC 61850 Comparison Table

| Feature/Category | IEC 61850 | Legacy Protocols | Benefit of IEC 61850 |

|---|---|---|---|

| Communication Model | Ethernet-based, object-oriented, abstract services | Serial communication, vendor-specific formats | High-speed, scalable, and standardized communication |

| Messaging | GOOSE, MMS, Sampled Values (SV) | Modbus, DNP3, IEC 60870-5 | Real-time event handling and wide functionality |

| Device Interoperability | Multi-vendor interoperability via logical nodes and data models | Limited or no interoperability | Easier integration and future system upgrades |

| System Architecture | Station Bus and Process Bus architecture | Hardwired analog and digital signal routing | Reduced wiring, modular design, improved diagnostics |

| Time Synchronization | Precision Time Protocol (PTP/IEEE 1588) | Basic time stamping or GPS-based sync | Microsecond-level time accuracy for event correlation |

| Scalability | Fully scalable with support for DERs, virtual substations, and WAMS | Difficult to scale or integrate with modern systems | Future-proofed for smart grid expansion |

| Cybersecurity | Supports IEC 62351 security standards | Minimal built-in security features | Enhanced protection against cyber threats |

| Maintenance & Cost | Lower long-term costs, remote diagnostics, simplified updates | Higher installation/maintenance costs due to hardwiring | Operational savings and faster troubleshooting |

GOOSE Messaging: Real-Time Communication

GOOSE is one of the most critical innovations in the IEC 61850 protocol. It allows IEDs to send event-based messages without waiting for a master controller. These multicast messages can be received by any subscribed device on the network, enabling real-time fault isolation, breaker tripping, and interlocking logic.

For example, when a fault is detected by a protection relay, it can instantly broadcast a GOOSE message that trips nearby circuit breakers—within 4 milliseconds—minimizing damage and improving system stability.

Process Bus vs. Station Bus: Streamlining Substation Design

The protocol’s support for both station bus and process bus enables a more modular and efficient substation design:

-

The station bus handles monitoring, metering, and supervisory control via MMS messages.

-

The process bus connects high-voltage equipment to IEDs using digitized sampled values, eliminating the need for complex analog cabling.

This separation reduces installation and maintenance costs while improving measurement accuracy and enabling remote diagnostics. Understand the importance of substation accessibility when upgrading legacy systems to smart grid standards.

Future-Proofing Substations with IEC 61850

The IEC 61850 protocol is designed with scalability in mind. Its object-oriented structure allows new devices and functions to be added without major system reengineering. This makes it ideal for:

-

Integrating distributed energy resources (DERs)

-

Supporting wide-area monitoring systems (WAMS)

-

Enabling edge-based protection and control

IEC 61850 also facilitates the development of virtual substations, where protection and control functions can be virtualized, improving flexibility and reducing hardware dependency. For safe operations alongside modern protocols, review our 6 Basic Rules to Ensure Substation Safety.

Conclusion

The IEC 61850 protocol is the cornerstone of modern substation automation, providing a robust, interoperable, and future-ready platform for intelligent grid operations. With features like GOOSE messaging, process bus architecture, and standardized data models, it enables faster fault response, reduced engineering effort, and seamless integration of diverse systems.

As the power grid evolves to accommodate renewable energy, electrification, and decentralization, IEC 61850 remains essential to building safe, smart, and scalable digital substations.

Related Articles

Sign Up for Electricity Forum’s Electrical Substations Newsletter

Stay informed with our FREE Electrical Substations Newsletter — get the latest news, breakthrough technologies, and expert insights, delivered straight to your inbox.

Vibration and Noise Control in T&D

Vibration and Noise Control in TD integrates acoustics, damping, isolation, and vibration analysis to mitigate resonance, reduce sound pressure, enhance structural dynamics, and ensure compliance with ISO standards across turbomachinery and thermal design.

What Is Vibration and Noise Control in TD?

Techniques to analyze and suppress vibration and noise in TD systems using acoustics, damping, and isolation.

✅ Modal analysis and FFT-based diagnostics guide root-cause mitigation.

✅ Implement damping, isolation, and tuned mass absorbers to cut resonance.

✅ Design enclosures, barriers, and silencers to meet ISO noise limits.

T&D industry trends and requirements have put great demand for low noise equipment with good long term performance. Amorim Cork Composites as a worldwide supplier to the T&D Industry has invested in R&D, establishing its VC (Vibration Control) product range and successfully implementing noise reduction solutions through vibration control.

In parallel, best practices in electrical substation design emphasize equipment layouts that minimize vibration coupling paths across structures.

It is very often that “just putting some rubber” to isolate structures creates an inefficient or even a vibration isolation problem, without taking into account the characteristics of the whole system: such as media environment and temperature, material stiffness adjusted to the application load, surface area, material transmissibility, as well as pad design techniques, like shape factor conformity. These are fundamental to a good anti-vibration material selection and consequent noise reduction.Through experience in T&D applications, Amorim Cork Composites has implemented a priority 4 step system approach in analysis and treatment of “noisy” equipment. Our 4 step approach focuses on the need to control vibration before it reaches the tank structure (and therefore closer to the source of vibration), impeding that structural vibrations on the tank are transformed into airborne noise through the amplitude vibration of the tank walls acting as “speakers”. Typical noise reduction gains (cumulative gains) can also be observed when designing with ACC methodology (values based on project statistics). For example, high-speed vacuum circuit breakers can introduce impulsive excitation that makes proper material selection critical.

The Noise Conundrum

As T&D equipment become larger and more powerful, due to electrical grid complexity and natural energy sources, general tank construction relies on rigidity and stiffness to reduce the amplitude of vibrations that reach the tank wall, which are then released as airborne noise.

Whilst the increase of stiffness of the tank is achieved through the use of U-beams and profiles, this also increases the actual natural frequency (fn ) of the tank structure closing in on the gap between the disturbing frequency coming from the active part. The closeness of these two frequencies lead to an amplification in transmissibility and consequent increase in noise.

Though optimal mechanical construction is imperative for the functional characteristics of the equipment, noise level restrictions are already today part of the Utilities requirements due to end consumer demand. Switching sequences in substation breakers may align with structural modes if not accounted for during design reviews.

Natural Frequency

All anti-vibration pads/materials, components and systems have a natural frequency (fn). In case of the anti-vibration pad the natural frequency, fn, is dependent upon the stiffness of the pad material, K, and the mass of the load that it is supporting (M). In elastomeric materials the fn is not only defined by the actual material but also by its thickness and shape (see shape factor). ACC has defined the natural frequency in various thicknesses under dynamic conditions for its materials.

Instrumentation such as capacitor voltage transformers can assist in correlating electrical disturbance frequencies with measured mechanical response.

Damping

Damping is the dissipation of energy, usually by releasing it in the form of low-grade heat. The loss factor quantifies the level of damping of a material, it is the ratio of energy dissipated from the system to the energy stored in the system for every cycle.

Due to corks closed cell structure filled with air, cork has a higher loss factor than rubber, essential to the damping function and consequent dissipation of energy. Our specific polymer formulations and the inclusion of cork, with unique compressibility and recovery characteristics, absorbs energy, yielding high material loss factors. Aligning materials selection with substation environmental design objectives helps meet community noise expectations.

Vibration Isolation

The performance of an isolation system is determined by the transmissibility of the system, the ratio of the Energy going into the system to the Energy coming out of the system. As a goal, vibration control design puts the disturbing frequency of the system in the isolation region The amount of damping in the isolation system will determine the height of peak transmissibility (fn) for the system. As damping increases, this peak value will decrease.

Amorim Vibration Control Materials exhibit significant material loss factors resulting in a lower amplification at resonance (fd=fn), giving them operational effectiveness over a broad range of frequencies.

Moreover, rigid bonding and grid connections defined by substation grounding practices can act as flanking paths unless isolation interfaces are specified.

Shape factor

Sf is the geometric measure for the shape of an anti-vibration pad, defined by the ratio of the loaded area and the area of the sum of the perimeter surfaces. The correct design of the shape fac-tor is important to achieve the cor-rect stiffness.

While rubbers are considered incompressible, needing space to dis-place the compressed volume, cork rubber displaces much less volume due to corks compression within itself (lower Poisson ratio), allowing for a wider Sf tolerance, which in turn affects the design robustness.

Anti-vibration pad selection and design roadmap

While rubbers are considered incompressible, needing space to dis-place the compressed volume, cork rubber displaces much less volume due to corks compression within itself (lower Poisson ratio), allowing for a wider Sf tolerance, which in turn affects the design robustness.

NOTE: careful analysis of the system is crucial; extra-ordinary loadings should be taken in to account such as oil mass, loads introduced through anchoring or significant connections that may impact the overall seating stress on the anti-vibration pad. As rule of thumb when possible, design on the lower end of the material stress range to account for load variations and long term creep effects. Integrating condition data into RTU and HMI redundancy strategies supports continuous monitoring during commissioning and service.

Decoupling Active Part Design

Due to the fact that every manufacturer has a unique design and clamping requirements, that is then replicated through its product range, every design needs to be uniquely evaluated.

The importance of adequate decoupling at the clamping points, significantly enhances the effectiveness of the interior vibration pads, preventing flanking paths from the active part to the tank structure. Amorim VC2100 is used for the decoupling function.

Structural damping design

Structural damping provides a means of converting mechanical energy (vibrations) in to low-grade heat, if cor-rectly implemented it can significantly reduce noise.

Thickness of the CLD is defined by the tank wall, in an optimized design the CLD thickness should be similar to the tank wall thickness; too thin will have minimum or no effect at all, it should be implemented in the interior wall. Amorim VC2100 is the selected material for the CLD

NOTE: In equipment where a shunt wall is present, the actual shunt wall can serve as the compressing element of the CLD against the interior tank wall, this construction will also reduce the vibrations that are passed on by the shunt wall to the tank structure due to the loss currents from the active part.

Related Articles

Electrical Substation Maintenance: Protecting Assets

Electrical substation maintenance involves testing, inspection, and diagnostics to prevent failures, reduce power outages, and extend equipment life. It enhances system reliability, supports compliance, and uses real-time data to detect early signs of wear or malfunction.

What is Electrical Substation Maintenance?

plays a vital role in ensuring the safety, reliability, and performance of modern power systems. Substations manage voltage levels, regulate power flow, and distribute electricity efficiently. Without proper inspection and servicing, substation equipment is more likely to fail—leading to power outages, equipment damage, and expensive downtime.

✅ Electrical substation maintenance is the routine inspection, testing, and servicing of equipment like transformers, circuit breakers, and protective relays to ensure system reliability and safety.

✅ It detects early signs of wear or failure using tools such as infrared thermography, power factor testing, and data analytics to prevent unplanned outages.

✅ Maintenance supports regulatory compliance, improves power flow and asset performance, and extends the life of critical infrastructure.

Electrical Transformer Maintenance Training

Substation Maintenance Training

Request a Free Training Quotation

By adopting proactive maintenance strategies supported by real-time monitoring, data analytics, and asset management tools, utilities can reduce the risk of faults, extend the life of high-voltage equipment, and maintain continuous service. Effective inspection and testing practices are best understood in the context of what an electrical substation is, since maintenance directly supports safe and reliable grid operations.

Why Substation Maintenance Matters

Routine substation maintenance is essential for:

-

Preventing equipment failures that can trigger widespread power outages

-

Improving safety and compliance with Department of Energy and utility standards

-

Supporting the reliability of transformers, circuit breakers, and protective relays

-

Enhancing overall grid stability and asset performance

Substations are high-voltage environments with complex systems. Maintenance efforts must target key assets like electrical substation transformer, circuit breaker in substation, and substation protection to ensure safe operation.

Condition Monitoring and Testing

Detecting early signs of equipment degradation is the cornerstone of a successful substation maintenance strategy. Key diagnostic tests include:

-

Power factor testing: Assesses insulation condition on transformers and switchgear

-

Dissolved gas analysis: Detects gases in transformer oil that indicate internal faults

-

Infrared thermography: Locates overheating in conductors and connections

-

Partial discharge testing: Identifies weaknesses in insulation systems

-

Transformer turns ratio (TTR) tests: Validate transformer winding conditions

These tests help identify performance declines early, thereby reducing the risk of failure and allowing for planned maintenance.

Preventive and Predictive Maintenance

There are two core approaches to substation upkeep:

-

Preventive maintenance includes routine inspections and scheduled servicing of equipment, such as substation components, to catch wear before it leads to breakdowns.

-

Predictive maintenance uses advanced tools like SCADA systems, thermal imaging, and load flow analysis to predict failures based on equipment behavior. This strategy relies heavily on real-time data analytics and management software.

Together, they support condition-based interventions that optimize costs and improve system reliability.

Asset Management and Lifecycle Optimization

Substations must be managed as part of a broader asset lifecycle strategy. Through continuous monitoring and diagnostics, utility companies can:

-

Schedule upgrades before critical failures

-

Extend the useful life of aging infrastructure

-

Reduce long-term capital expenditures

Substation automation plays a crucial role in gathering performance data and feeding it into modern asset management systems. This integration allows planners to align maintenance with long-term investment goals.

Safety and Compliance

Substations are inherently hazardous. Maintenance helps enforce substation grounding requirements and ensures fault detection systems operate properly. This protects personnel and ensures compliance with regulatory guidelines, such as those from the Department of Energy and OSHA.

Proper maintenance of protective devices and grounding systems reduces the risk of arc flash events and improves emergency response preparedness.

Role of Technology in Modern Substation Maintenance

Technology is transforming substation maintenance through:

-

Real-time condition monitoring: Sensors and SCADA deliver up-to-the-minute performance data

-

Digital twins: Simulate equipment behaviour to optimize servicing schedules

-

Automated fault alerts: Notify teams of failures before they escalate

-

AI-powered analytics: Enhance decision-making for predictive repairs

These tools enable teams to address failures more quickly and allocate resources more efficiently.

To learn more about how technology supports maintenance strategies, visit our digital substation page.

FAQs

What types of equipment are included in substation maintenance?

Transformers, circuit breakers, protective relays, switches, and grounding systems are key. These components regulate voltage, isolate faults, and protect the grid.

How does maintenance reduce outages?

Maintenance detects faults early, helping avoid unplanned outages. It improves electrical substation reliability and extends equipment life.

How is technology changing maintenance practices?

Digital tools, such as remote sensors, SCADA, and AI, now monitor systems in real-time. This enables faster, more targeted servicing and smarter long-term planning.

What standards apply to substation maintenance?

The Department of Energy and IEEE establish guidelines for inspections, safety testing, and the performance of power assets.

Where can I learn more?

Enroll in our substation maintenance training to build your skills in diagnostics, testing, and compliance.

Related Articles

Circuit Breaker In Substation Explained

A circuit breaker in substation systems protects transformers and grid infrastructure by interrupting faults like overloads or short circuits. Learn how they work, their types, maintenance, and evolving technology.

Electrical Transformer Maintenance Training

Substation Maintenance Training

Request a Free Training Quotation

What is a circuit breaker in a substation?

It is a critical protective device that interrupts electrical current during fault conditions like short circuits or overloads.

✅ Automatically interrupts electrical current during faults to protect substation equipment like transformers and busbars.

✅ Ensures grid reliability by isolating faulted sections and maintaining power flow to unaffected areas.

✅ Works with protective relays and control systems to detect overloads, short circuits, and abnormal conditions.

These high-performance switches are crucial for maintaining power system stability, protecting expensive equipment such as transformers, and preventing widespread power outages. Whether in a utility-scale transmission yard or an industrial distribution hub, the breaker’s ability to detect faults and isolate problems makes it the backbone of substation protection systems.

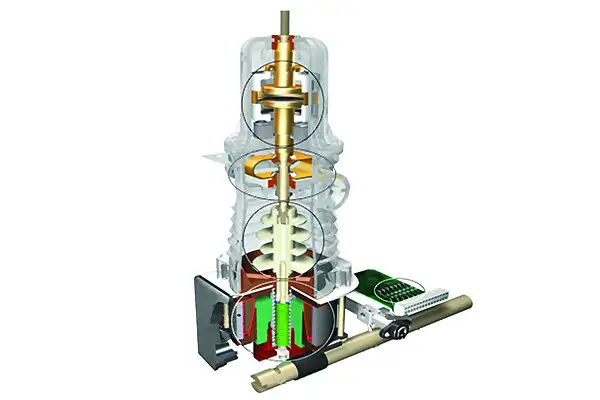

A circuit breaker in substation is a key component in electrical power systems, designed to interrupt the flow of electricity when a fault occurs, such as a short circuit or overload. Depending on system design, these devices can operate manually or automatically and come in various types, including air, vacuum, oil, and SF₆ gas. When triggered, the breaker relies on arc extinguishing mechanisms that either cool the arc with insulating materials or eliminate it entirely through vacuum or gas-based solutions. Their high dielectric strength enables them to withstand and effectively isolate high-voltage currents. Substations ensure system stability, minimize downtime, and protect equipment, such as transformers and busbars, from damage while supporting real-time monitoring and automated grid responses.

Role of the Circuit Breaker in Substation Protection

In substations, circuit breakers serve as the first line of defence. When abnormal current is detected—due to equipment failure, insulation breakdown, or lightning—a breaker opens its contacts to interrupt the current flow. This rapid response prevents severe equipment damage, minimizes safety hazards, and ensures reliable power delivery.

Circuit breakers work in conjunction with protective relays and disconnectors to isolate faults while allowing the rest of the system to remain operational. This selectivity is especially crucial in interconnected grid environments where continuity of supply must be preserved.

To explore how these systems are integrated, see our page on electrical substation design.

Types of Substation Circuit Breakers

Substation circuit breakers vary based on their arc-quenching medium and voltage rating. Each type is suited to specific applications and offers advantages and limitations:

-

Air (ACB): Use compressed air to extinguish arcs. These are typically used in low-voltage systems and offer simple construction but require regular inspection.

-

Vacuum (VCB): Suitable for medium-voltage levels (up to 38 kV), VCBs extinguish arcs in a vacuum, ensuring minimal wear and extended service life.

-

Oil (OCB) use insulating oil to suppress arcs. They are more common in legacy systems and require ongoing maintenance due to oil degradation.

-

SF₆: These breakers, employed in high-voltage substations, use sulphur hexafluoride gas for superior arc quenching and insulation. While highly effective, they present environmental concerns due to the gas’s impact on greenhouse gases.

To understand how different transformer systems pair with circuit breakers, visit our electrical substation transformer overview.

Protection, Control, and Grid Stability

Circuit breakers form part of a broader substation protection and control system that includes current transformers, voltage transformers, and digital protection relays. When a relay detects an abnormality, it sends a signal to the breaker to open, thereby isolating the faulty section. This automated coordination is crucial in modern substations, particularly as grids integrate renewable energy sources and smart grid technologies.

Many modern substations now use digital relays, IEDs (Intelligent Electronic Devices), and SCADA systems for real-time monitoring and automation. Learn how circuit breakers integrate with these systems in our article on

substation automation systems.

These control systems allow breakers to be operated remotely, analyze fault data, and optimize asset performance, thereby enhancing substation responsiveness and reliability.

Maintenance and Inspection Practices

Routine maintenance is vital to ensure breaker reliability. The type of breaker determines specific servicing needs:

-

Oil and SF₆ breakers require careful monitoring of fluid or gas levels to prevent insulation failure.

-

Vacuum and air breakers require less maintenance but still need to be inspected for wear and mechanical issues.

Key inspection tasks include:

-

Verifying insulation resistance

-

Testing trip and close mechanisms

-

Checking for leakage or contamination

-

Reviewing control circuitry and relay coordination

Explore our electrical substation maintenance programs, which outline testing techniques and predictive diagnostics, for practical guidance on these procedures.

Environmental and Safety Considerations

Safety is paramount when working around high-voltage circuit breakers. Operators must use appropriate PPE and follow strict lockout/tagout procedures to prevent arc flash injuries and electrical shock. Circuit breakers, particularly those using SF₆ gas, also carry environmental risks.

To understand how breakers help mitigate shock hazards and arc incidents, refer to our

Electrical Substation Components Safety Guide.

Growing concerns about SF₆’s environmental impact push the industry toward eco-friendly alternatives. Dry air and vacuum interrupters are gaining traction for their reduced greenhouse footprint.

Future Trends in Breaker Technology

The future lies in digitalization, remote diagnostics, and sustainability. Innovations include:

-

IoT-connected sensors for condition-based maintenance

-

AI algorithms for predictive failure detection

-

Eco-efficient breakers using clean-air technologies

As utilities adapt to the demands of electrification and renewable integration, they will continue to evolve, ensuring safety, reliability, and efficiency in the next generation of power grids.

Frequently Asked Questions

What is the main function of a circuit breaker in substation?

To detect and interrupt fault currents, protecting transformers and maintaining system reliability.

How often should they be inspected?

Maintenance intervals vary by type, but annual testing and inspection are generally recommended.

Are SF₆ breakers still widely used?

Yes, but many utilities are shifting toward more environmentally friendly alternatives due to SF₆'s global warming potential.

Related Articles

Capacitor Voltage Transformer in Substation

A capacitor voltage transformer steps down extra high voltage (EHV) for metering and protection in substation applications while offering communication capabilities. It plays a dual function in modern power systems by combining voltage scaling and power line carrier signal coupling.

What is a Capacitor Voltage Transformer in Substation

A capacitor voltage transformer (CVT) in substation applications is a high-voltage device that performs multiple essential functions. It is widely used in EHV systems for both measurement and communication. Here's what defines a CVT:

✅ Steps down EHV from transmission lines to a standardized secondary voltage for metering and protective relays.

✅ Functions as a coupling device for power line carrier (PLC) systems, allowing high-frequency communication signals to travel over the same conductors as power.

✅ Uses a capacitor voltage (V) divider with capacitor C1 and other capacitor elements, making it cost-effective and compact compared to electromagnetic voltage transformers.

For a full technical overview of CVT design and principles, visit our Capacitor Voltage Transformer page.

Electrical Transformer Maintenance Training

Substation Maintenance Training

Request a Free Training Quotation

Capacitor Voltage Transformer in Substation

A capacitor voltage transformer in substation settings is critical in power systems. It steps down EHV from transmission lines to a secondary voltage suitable for measuring instruments and metering protective equipment. Additionally, it performs a dual function by enabling communication across the grid through power line carrier signals. Understanding how this device operates and where it excels is vital for substation engineers, utility planners, and maintenance professionals. To understand how CVTs integrate into the overall grid infrastructure, see our article on: What is an electrical substation?

Its ability to couple high-frequency signals sets it apart, making it a key component in power line carrier communication systems. This dual function eliminates the need for additional coupling capacitors, optimizes space, and reduces costs in substation layouts. To explore other key devices in a substation, including transformers and breakers, refer to our page on electrical substation components.

Working Principle and Construction

The CVT uses a capacitor voltage divider formed by stacked capacitor elements, typically capacitor C1 and additional units, connected in series across the HV line. The divided V is passed through a tuning reactor to adjust for phase alignment and resonance at the desired frequency. An electromagnetic unit, or intermediate transformer, converts this adjusted signal into a lower, measurable voltage, delivered via the secondary winding.

The CVT uses a capacitor voltage divider formed by stacked capacitor elements, typically capacitor C1 and additional units, connected in series across the HV line. The divided V is passed through a tuning reactor to adjust for phase alignment and resonance at the desired frequency. An electromagnetic unit, or intermediate transformer, converts this adjusted signal into a lower, measurable voltage, delivered via the secondary winding.

A circuit diagram often depicts this process, illustrating the capacitive divider, reactor, transformer, and output connections. The absence of a large magnetic core allows CVTs to maintain a compact design, which is especially beneficial in EHV installations. For a deeper understanding of transformer technologies in substation environments, visit our guide on the electrical substation transformer.

Applications in High Voltage Substations

The capacitive voltage transformer is most commonly used in EHV substations where cost, footprint, and functionality are critical. Because of its compact size and built-in ability to couple high-frequency signals, the CVT excels in applications such as:

-

Voltage measurement for measuring instruments

-

Operation of metering protective relays

-

Integration into power line carrier communication networks

-

Control systems requiring reliable V data

In regions adhering to North American standards, CVTs are typically aligned with IEEE and CSA V ratings and insulation classes. To explore how CVTs and other automation technologies are modernizing substations, see our article on substation automation.

Comparison with Electromagnetic Voltage Transformers

While CVTs and electromagnetic voltage transformers serve as voltage transformers, each has distinct advantages. CVTs are more economical for HV applications due to their lightweight construction and multi-role functionality. On the other hand, electromagnetic units tend to provide better transient response and higher accuracy in rapidly changing conditions. To learn how other equipment, like circuit breakers, fits into V control and protection, view our article on the circuit breaker in a substation.

The capacitor voltage transformer is the preferred solution where space, budget, and communication integration are priorities. Where ultra-precise measurement or fast transient detection is necessary, traditional EMVTs may still be favored.

Maintenance, Testing, and Operational Considerations

Maintaining a CVT involves regular inspection of insulation performance, especially across capacitor elements and the secondary winding. Key tests include:

-

Dielectric loss factor (tan delta) testing

-

Insulation resistance checks

-

Physical inspections for oil leaks, corrosion, or damage

-

Verification of output V against expected values

Failures often stem from moisture ingress, insulation aging, or tuning reactor detuning. Although many modern units are designed for long intervals between services, substations relying on CVTs for measuring instruments or power line carrier systems cannot afford unexpected outages. For best practices in field testing and inspection, check our methodology for electrical substation maintenance.

Testing Procedures and Checklist:

Regular field testing of capacitor voltage transformers is essential to ensure reliability in substation operations. Beyond routine inspections, engineers follow a structured approach that addresses both the health of insulation and its functional performance.

Expanded Testing Procedures and Checklist:

-

Perform visual inspections on bushings and capacitor stacks before energization.

-

Carry out partial discharge measurements to detect early insulation breakdown.

-

Confirm resonance tuning by checking the reactor adjustment against the rated frequency.

-

Apply secondary injection tests to confirm correct relay operation via CVT outputs.

-

Record and trend dielectric test results to detect gradual insulation degradation.

Case Example: In one utility, periodic tan delta testing of CVTs revealed rising dielectric losses in capacitor C1 stacks. Early replacement avoided sudden failure and prevented a costly transmission outage. Another case involved tuning a reactor after detuning due to a lightning surge, which was identified through secondary voltage distortion patterns.

Operational Integration: Modern CVTs are being fitted with digital sensors that continuously monitor secondary voltage waveforms and dielectric conditions. These diagnostic tools enable predictive maintenance, reducing downtime and aligning with smart substation strategies.

Frequently Asked Questions

What is the primary function of a capacitor voltage transformer?

The main function is to step down EHV from transmission lines to a lower secondary voltage used for metering, protective devices, and to enable communication via power line carrier signals.

How does a CVT differ from an electromagnetic voltage transformer?

A CVT uses a capacitor voltage divider and electromagnetic unit, making it compact and cost-efficient for EHV applications. EMVTs rely solely on magnetic cores and offer better accuracy for fast transients.

What are the key maintenance practices for CVTs in substations?

Essential practices include dielectric testing, inspection of capacitor C1 and other components, and functional verification of the secondary winding output to ensure reliable operation.

Related Articles

Construction Drones

Construction drone enables RTK surveying, LiDAR mapping, photogrammetry, and thermal inspection for electrical infrastructure, substations, and transmission lines, supporting BIM updates, progress tracking, orthomosaic planning, and safe, remote condition monitoring.

What Is a Construction Drone?

A construction drone is an unmanned aerial system for RTK surveying, LiDAR, and thermal inspection of electrical assets.

✅ RTK/GNSS mapping enhances substation as-built accuracy

✅ Thermal imaging detects faults in switchgear and busbars

✅ LiDAR/photogrammetry supports BIM updates and clash checks

Fingertip Cost Savings for T&D Industry Infrastructure

The surge of interest in construction drones to be used in the T&D infrastructure construction process is growing and advancing in leaps and bounds as the North American utilities companies realize the multi-potential uses of this technology. Not since the introduction of the mobile computer devices to the utilities sector has there been so much recognizable potential for this technology, in so many different capacities. The drone world has begun to turn its eye to the electrical construction industry regarding the building of power plants to electrical substations to distribution systems, and the potential for savings and improvements is staggering. The drone technology for surveying, safety, security and even resource tracking is now available, literally at ones fingertips.

T&D Construction Booms

In 2015 North American Electric T&D industry exceeded $49 billion on T&D construction projects from power plants to electrical substations to distribution systems. That is higher than any of the previous years since the 2009; To ensure these investments translate into reliable assets, many teams reference an electrical substation design roadmap when scoping upgrades and new builds.

Regulatory requirements and incentives, fueled by the need to improve the reliability and capacity of the North American T&D network, provides an opportunity for utilities and developers to make substantial investments to replace, upgrade, and expand new and existing T&D infrastructure. Modern reliability goals are increasingly met through substation automation that integrates protection, control, and monitoring.

T&D Infrastructure Overview

- Power Plant - Electricity is generated at the power plant at a relatively low voltage

- High Voltage Transformer – Voltage is increased by transformers from hundreds to hundreds of thousands of volts for transportation over long distances.

- Transmission Lines – High voltage transmission lines carry power from the power plant to the substations.

- Transmission Substations – Contain high voltage switches allowing the connection, isolation or maintenance of high-power lines.

- Distribution Substations – Contain transformers that “step-down” reduce the high voltage power to a lower level for distribution to the end user.

- Distribution Systems – Main/primary power lines and low voltage secondary power lines deliver electricity via overhead or underground wires/cables to the end user.

- Service Connection – Power line that connects the electricity to a meter at the end users location.

For readers new to the topic, this flow is anchored by understanding what an electrical substation is and how it fits between generation and load.

Construction Drones

Companies like 3D Robotics, DroneDeploy and Kespry to name a few, offer “smart construction drones”. As an example of the seemingly endless technology, Kespry’s drone the Kespry 2.0 can fly over 150 acres in 30 minutes providing aerial data. Even self-built and off the shelf drones have the capability to provide an astounding range of information with the use of basic attachments and software. Drone imagery can directly support 3D substation design utilizing AutoCAD by validating clearances and as-built conditions.

Listed below are a few of the technically advanced attributes which the new “smart drones” are capable of producing.

Site Mapping with Drones

- completing accurate 3D models of existing and new structures

- overlays of the original plans with the recorded data

- accurate topographical maps

- temporary roads and structures can be planned in advance and plotted into the 3D maps

These models become foundational data for planning a digital substation where systems are engineered around accurate geospatial context.

Materials & Inventory Controls

- determine the size of stockpiles like gravel, lumber, and rebar

- identify equipment and machinery on site

- inventory updates, useable materials automatically assessed and equipment requirements calculated

- provides accurate data for the project manager

- eliminate unnecessary spending

- real time information

- real time and forecasted business decisions.

Further Features

- cloud connectivity

- monitor progress (on more than one project if necessary)

- show progress to clients

- keep extensive 3D records of the changes on a day by day basis

- structural inspection

- authenticate work done from office or home

- security service; perform automated patrols of a defined area, recording security footage (even utilizing infrared cameras)

Routine visual patrols also help prioritize maintenance on critical components like the substation breaker so outages can be prevented proactively.

There are many construction industry security services and construction industry management services which are now realizing the advantages of employing the use of drones in the building of power plants to electrical substations to distribution systems. Basically one construction drone can perform most of the features mentioned above without the requirement of specialist equipment. Their software handles the raw data and translates it into meaningful and actionable information throughout all aspects of a T&D infrastructure construction project and post project. The cost savings and time savings compared to traditional methods will be staggering and very hard for an electrical utilities company to ignore. Upskilling project teams through focused electrical substation training ensures drone-derived insights are translated into safe, compliant decisions.

Related Articles

Safe Work Practices for Circuit Breakers

Safe circuit breakers provide overcurrent protection, short-circuit interruption, and arc-fault mitigation for residential, commercial, and industrial panels, ensuring electrical safety, code compliance, selective coordination, and reliable fault isolation across MCB, MCCB, and GFCI devices.

What Are Safe Circuit Breakers?

Devices that detect overcurrent or faults and interrupt flow to prevent fires, equipment damage, and shock.

✅ Rated by trip curve, interrupting capacity, and voltage class

✅ Supports AFCI/GFCI, thermal-magnetic or electronic trip units

✅ Ensures selective coordination and arc energy reduction per code

In our daily work lives, we often are required to reset circuit breakers, either molded-case or power drawout types. We may perform this task several times each day without giving it a thought. Maybe we should. Low-voltage circuit breakers are switches that have overcurrent protection. Switches are designed to make and break electrical contacts under load—unlike disconnects, which are not load-break devices. If it is a molded-case circuit breaker marked “SWD” or switching duty, they can be used to operate banks of fluorescent lighting. Low-voltage power (drawout) circuit breakers are often used as across-the-line starters. Obviously, they can handle the punishment. In many facilities, vacuum designs are favored for frequent switching, and resources like the Electricity Forum's guide to a vacuum circuit breaker explain performance characteristics relevant to maintenance planning.

What really happens, though, when a circuit breaker opens and closes under high currents, such as when used for starters or when they interrupt fault level currents? Most people don’t know, just assuming they are made for the task, so everything is good. That is not the case. Operating a circuit

breaker during high current conditions causes the breaker to deteriorate internally. Metal is sprayed into the arc chutes, carbon is spread around and the intense heat of the arc deteriorates the surrounding materials. The worst part, though, is that the lubricant that’s applied to the circuit breaker’s contact pivot points will dry out over time, eventually becoming gummy (slowing the breaker down) and finally flaking off, which can cause the breaker to freeze. Proper maintenance and inspection can catch these problems before they become critical, but many people have no specific program for their breakers, especially molded-case breakers. Below are listed some points to keep in mind when operating circuit breakers. A robust inspection program should also account for grounding integrity, and the Electricity Forum's overview of substation grounding highlights how return paths and bonding affect fault energy during operations.

POINT #1

Never stand directly in front of electrical equipment when it’s being operated. I’ve caught grief from other lessenlightened electrical workers for years by standing to the side of whatever I’m operating, extending my left arm fully, turning my head and then operating it. We used to call it the “left-hand rule” where you always used your left hand, because you needed your right hand to fill out the forms after the accident. Let’s change that up just a bit. Let’s call it the “hinge-side rule”. In most metal-enclosed devices, the latch is the weak point—especially if it is a single-point handle. If it has several screws and they are properly fastened, they mayhold, but doors will usually pop open on the latch side during an arc event. I now stand on the hinge-side when operating breakers. I may break an arm, but the door should provide some shielding from the arc flash and blast. I’ve talked to several people over the years who have said that the door did provide some shielding; you just can’t count on it. I’d rather be beat than baked. I still find it difficult to completely trust in arc-rated personal protective equipment (PPE) and equipment when there are so many variables concerning an arc flash event. Maybe you’re more trusting than I. For additional perspective on arc-flash-minded work practices, review the Electricity Forum's discussion of basic substation safety rules that reinforce situational awareness and barrier use.

POINT #2

If wearing an arc-rated face shield (not a hood), do not turn your head when operating equipment, face it. If you face the arc source the face shield can do its job. Turn your face and you now have an arc flash scoop. As with standing on the hinge-side of equipment, not everyone would agree with me on this, but it’s a personal choice and that is mine. In the 2012 edition of NFPA 70E, titled Standard for Electrical Safety in the Workplace, a nationally accepted standard of the National Fire Protection Association (NFPA), it is now required to use an arc-rated balaclava and face shield for all tasks for Hazard/ Risk Category 2 (HRC 2). Our concern was that the back of the head may be exposed to the arc plasma, even at HRC 2 levels. Understanding controlled approach boundaries also matters, and the primer on substation accessibility outlines how access controls intersect with PPE selection and task planning.

POINT #3

Have a check list when preparing to rack a low-voltage power circuit breaker. “What?” you say, “I’ve been doing this for years.” According to a report by Centers for Disease Control and Prevention (CDC) and The National Institute for Occupational Safety and Health (NIOSH), that’s when we are most likely to have an accident. Contextualizing tasks within the broader system helps too, and this overview of what an electrical substation is clarifies how protection and control schemes influence breaker operation.

POINT #4

Notice that it is experienced workers (10 plus years) that have a jump in accidents. We know how to do it. We also know shortcuts—or bad habits—we’ve picked up over the years. A check list keeps us on track, so if we are distracted or the work is interrupted, we know where we left off. Some items to have on that checklist:

a) Make certain the load is dropped before opening or closing the breaker. The breaker is placed under the most stress when opening and closing under load (or especially a fault, but that opens it automatically). It only makes sense to reduce that stress when operating the breaker.

b) Make certain the breaker actually is open—especially if you are to rack a breaker that is already showing OPEN. Most breakers use a spring-loaded indicator that is driven by small linkages. Often, on older breakers especially, these indicators were spring-loaded to the OPEN position. I don’t know why it would be that way, but it is. It’s not open until we hit the TRIP button and verify it’s open.

c) Be certain the door is properly latched. Even though it would probably come open during a failure, it still would slow things down. Also, remember about broken vs. baked. All fasteners should be installed and properly secured before proceeding.

d) Wear the proper PPE. There are a million reasons not to wear PPE and only one reason to wear it—you’ll go home instead of to the hospital. Use your common sense here, also. NFPA 70E directs us to perform a Hazard/Risk Analysis before we engage in hazardous electrical work. We judge the hazard (whatever the incident energy would be) and also the risk. If the equipment is old and poorly maintained, then the risk is increased. I think I’d wear more PPE, not less.

e) Pull the control fuses, if possible. Usually, low-voltage breakers don’t make this a viable option, but most metalenclosed breakers can have their control fuses pulled.

f) Rack with the door closed, if possible. Sometimes, the door must be open to rack a breaker. If that’s the case, use a longer racking handle. The incident energy decreases by the inverse square of the distance, so a six-to-twelve inch increase in distance from the arc source can reduce the heat considerably.

The more distance the better, or as I like to say, “Distance is our friend”. Design differences between fixed-mounted gear and a substation breaker can affect racking procedures and recommended standoff distances during maintenance.

g) If the breaker is operated in the TEST position, make double certain it is open before you rack it into the CONNECTED position. Yes, there are interlocks, but it’s like my dad would tell me, “Never trust your life to a mechanical device”. If it’s electrical or mechanical it is not a question of if, but when it’s going to fail. Don’t roll the dice. There are other points that could be made on this topic, but these are the ones that stick out to me. If you operate breakers with respect and take into consideration their shortcomings, you can safely operate them. If you are unsure about application limits, this primer on a circuit breaker in a substation details duty cycles and interrupting ratings that inform safe operation.

From: Electrical Testing and maintenance Handbook, volume 11, The Electricity Forum