Industrial Electrical Power

Construction Electrical Safety Practices

Construction electrical safety ensures OSHA compliance using NFPA 70E and NEC guidelines, lockout/tagout, PPE, GFCI protection, grounding, arc-flash mitigation, insulated tools, and safe temporary power practices for hazard control on construction sites.

What Is Construction Electrical Safety?

Construction electrical safety defines standards to prevent shock, arc flash, and fire risks on job sites.

✅ Apply NFPA 70E and NEC for temporary power and grounding

✅ Use GFCI, LOTO, PPE, and insulated tools to control hazards

✅ Test circuits, verify grounding, and maintain shock/arc-flash boundaries

Construction electrical safety is essential for protecting workers from serious hazards such as arc flash incidents, electric shock, and contact with energized equipment. Construction sites' constantly changing and often unpredictable nature demands strict attention to safety practices. Adopting well-defined procedures—such as proper grounding, lockout/tagout protocols, the use of personal protective equipment (PPE), and compliance with standards like NFPA 70E and CSA Z462—plays a critical role in preventing injury, ensuring worker safety, and meeting regulatory obligations in both Canada and the United States. For a concise overview of minimum controls and compliance needs, see electrical safety requirements that translate standards into actionable steps.

Request a Free Training Quotation

Common Electrical Hazards on Job Sites

Construction sites present a variety of electrical risks. Workers may encounter energized circuits or unintentionally come into contact with overhead power lines. Equipment like ladders or scaffolding can become deadly when they brush against live conductors, especially if workers are unaware of the hazard. Additional dangers include the improper use of extension cords, damaged plugs, and poorly maintained temporary power sources. Even falls from height can result in electrocution if contact is made with exposed wiring or energized panels during the fall. Addressing these exposures within a formal program aligns with electrical safety in the workplace principles that emphasize hazard identification and controls.

Preventing Electrical Incidents on Construction Sites

Electrical and non-electrical workers must follow established safety procedures to minimize risks. Proper PPE—such as insulated gloves, face shields, and flame-resistant clothing—should be worn whenever there is a risk of electrical exposure. To ensure circuits are properly isolated, lockout/tagout procedures must be strictly followed when working on energized systems. Safety should be a team effort, with supervisors and foremen ensuring compliance and identifying potential hazards before work begins. Clear roles and documented procedures for qualified and unqualified persons are outlined in electrical safety work guidance that supports consistent execution.

All workers, especially those new to the electrical field, should receive comprehensive safety training to help them understand how to avoid dangerous situations. Employers must also implement safety programs that include regular inspections, the use of ground fault circuit interrupters (GFCIs), and proper maintenance of grounding systems. Organizations can strengthen competencies through electrical safety training that combines theory with practical application.

Electrical Safety Standards and Training Requirements

In the U.S., electrical safety on construction sites is governed by Occupational Safety and Health Administration (OSHA) regulations. In Canada, similar standards are maintained by the Canadian Standards Association (CSA), with CSA Z462 outlining specific requirements for arc flash and electrical hazard protection. Understanding how to determine incident energy and select PPE categories is central to arc flash training requirements that many organizations incorporate into policy.

Both NFPA 70E and CSA Z462 provide frameworks for evaluating risks, choosing the right PPE, and applying proper work methods around energized equipment. These standards are essential for any construction site safety program and should be integrated into company policies and daily practices. These methods are equally applicable in plant settings and process industries under industrial electrical safety best practices.

Training Opportunities and Resources

The Electricity Forum offers specialized construction electrical safety training programs to ensure workers are equipped with the necessary knowledge. These include NFPA 70E and CSA Z462 Arc Flash Training courses, designed to build awareness, strengthen safety practices, and support regulatory compliance across job sites in both Canada and the United States. Blended learning options and refresher modules are addressed in arc flash safety training resources that help maintain proficiency.

If you want to enhance your team’s safety readiness, request a free training quotation and find out how we can help you develop a safer, more compliant workforce.

Related Articles

Test Your Knowledge About Arc Flash!

Think you know Arc Flash? Take our quick, interactive quiz and test your knowledge in minutes.

- Instantly see your results and score

- Identify strengths and areas for improvement

- Challenge yourself on real-world electrical topics

Latest IEP Content

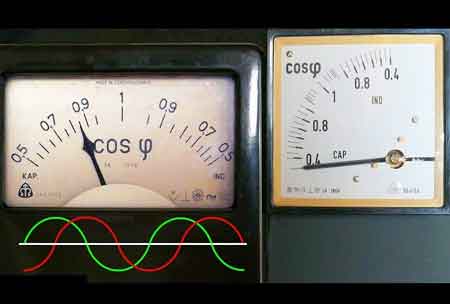

Power Factor Meter Explained

A power factor meter measures the efficiency of electrical energy usage by calculating the ratio of real power to apparent power. It helps identify energy loss, improve system performance, and ensure optimal power quality in industrial, commercial, and utility settings.

What is a Power Factor Meter?

It is an electrical measuring device that indicates the phase difference between voltage and current, helping assess energy efficiency and optimize load usage.

✅ Measures the ratio of real power to apparent power

✅ Helps improve power quality and reduce energy loss

✅ Used in industrial, commercial, and utility electrical systems

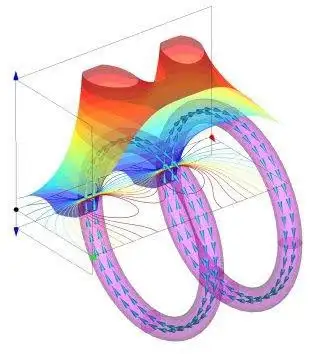

A power factor meter measures the efficiency of electrical usage by comparing the real power (P) and the apparent power (S, measured in kVA). Commonly used in energy audits and industrial systems, it helps identify poor power factor (PF) conditions and supports improvements in quality and cost savings.

It is an essential instrument used to measure the PF of an electrical system. The PF is the ratio of P to kVA and represents the efficiency with which electricity is used. It is expressed as a number between 0 and 1, with a higher PF indicating greater efficiency. Understanding and monitoring PF is crucial for optimizing energy consumption and reducing electricity costs. Our Power Factor Explained resource provides foundational knowledge ideal for those new to the concept or seeking a quick refresher. If you're looking to improve your system’s efficiency, our article on Power Factor Correction explores effective solutions using capacitors and controllers.

Power Quality Analysis Training

Request a Free Power Quality Training Quotation

How to Use a Power Factor Meter for Energy Optimization

Improving PF is a crucial step towards achieving energy efficiency. A low PF indicates that a significant portion of the electrical current is not being used to perform useful work. This wasted energy translates into higher electricity bills and increased carbon emissions. By using a PF meter to identify and correct low PF, businesses and individuals can reduce their energy consumption and contribute to a more sustainable future.

PF correction equipment plays a vital role in improving electrical efficiency monitoring by optimizing the balance between real and reactive power (Q). Through real-time monitoring, facilities can identify inefficiencies and implement solutions, such as installing capacitor banks, to support kVAR compensation. These measures contribute significantly to energy cost reduction by minimizing waste and enhancing overall system performance.

Installation Tips

Proper installation of a power factor meter is crucial for obtaining accurate measurements and ensuring long-term reliability. Begin by identifying the appropriate location—typically at the main electrical panel or near the load where Q is highest. Ensure the meter is installed downstream of any PF correction equipment to avoid false readings. Wiring should follow the manufacturer's guidelines, and the use of shielded cables can help minimize signal interference. Grounding and secure mounting are critical to prevent vibration or electrical noise. For three-phase systems, verify correct phase alignment during setup to maintain data integrity.

Best Practices for Maintaining Accurate Readings

Maintaining accurate readings from your power factor meter involves both environmental control and routine calibration. Meters should be kept in areas with stable temperature and humidity to avoid sensor drift. Avoid placing meters near heavy machinery or transformers that could emit electromagnetic interference. Regular calibration—ideally every 12 to 24 months - ensures the reliability of the data. Most digital meters offer software-based calibration tools, while analog models may require manual adjustment. Always document each calibration session and track long-term performance trends to catch potential issues early.

Comparing Power Factor Meters: Analog vs. Digital

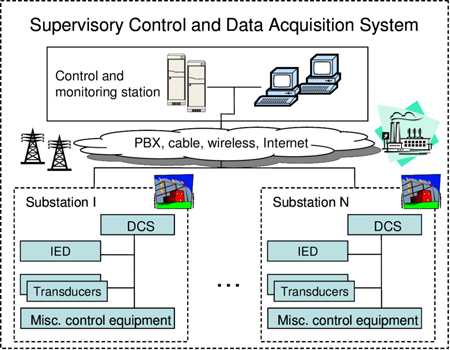

An analog or digital power factor meter offers distinct advantages depending on your application. Analog models are often more cost-effective and easier to operate, making them ideal for basic monitoring in smaller setups. However, digital meters offer greater precision, data logging capabilities, and real-time display features. They often include software integration for advanced electrical efficiency monitoring and remote diagnostics. For industrial or utility-scale systems, digital meters are the preferred choice due to their compatibility with SCADA and energy management systems. Consider your budget, technical requirements, and need for data integration when choosing between the two.

Integrating PF Meters with Smart Grids

A Power factor meter plays a key role in smart grid environments by enabling real-time monitoring and automated decision-making. When integrated with smart grid infrastructure, these meters can communicate with distributed energy resources (DERs), demand response systems, and advanced metering infrastructure (AMI). This integration enables utilities and large facilities to enhance grid stability, optimize kVAR compensation, and manage load profiles more effectively. Compatibility with communication protocols like Modbus, BACnet, or Ethernet/IP ensures seamless data flow across systems. As the smart grid evolves, they are becoming an indispensable tool for intelligent energy management.

PF Correction

PF correction is the process of improving PF by reducing the amount of Q in an electrical system. This is typically achieved by adding PF correction equipment, such as capacitor banks, to the circuit. These devices counteract the effect of inductive loads by supplying Q locally, reducing the burden on the electrical system and improving the overall PF. For more information, refer to Power Factor Correction.

Choosing the Right PF Meter for Your Application

A power factor meter is critical in industrial settings, where large motors and other inductive loads are prevalent. Maintaining a high PF is crucial for ensuring efficient operation and minimizing energy costs. In industrial applications, meters are used to monitor PF in real time, identify potential problems, and optimize the performance of electrical equipment. A digital power factor meter is ideal for tracking real-time efficiency metrics in three-phase systems.

Three-Phase

Three-phase electricity is a common type of electrical energy used in industrial and commercial settings. In three-phase systems, electricity is delivered through three conductors, each carrying an alternating current that is 120 degrees out of phase with the others. Measuring PF in three-phase systems is more complex than in single-phase systems, as it involves considering the PF of each individual phase as well as the overall system PF.

Analyzers

A power factor meter is often integrated into more comprehensive analyzers. Analyzers are sophisticated instruments that provide detailed information about various electrical parameters, including voltage, current, energy, and harmonics. These devices are used for troubleshooting PQ problems, optimizing energy consumption, and ensuring the reliable operation of electrical equipment.

Cost Savings

Improving PF can lead to significant cost savings, especially for businesses with high energy consumption. By reducing Q and improving efficiency, businesses can lower their electricity bills and avoid penalties imposed by utility companies for low PF. Additionally, PF correction can reduce the load on electrical infrastructure, potentially extending the lifespan of equipment and reducing maintenance costs.

Frequently Asked Questions

Why is monitoring PF important in industrial and commercial settings?

Monitoring PF is crucial because a low PF indicates inefficiency, which can lead to higher energy bills and potentially increased equipment maintenance costs. Many utility companies charge penalties for low PF, so keeping it close to 1.0 can save money. A high PF also reduces strain on the electrical infrastructure, allowing for more efficient operation and potentially extending the lifespan of equipment. To better understand how PF is calculated, visit our detailed guide on the Power Factor Formula, which breaks down the relationship between real, reactive, and apparent energy.

How does a power factor meter differ from other electrical meters?

Unlike voltmeters or ammeters, which measure voltage and current, respectively, a PF meter specifically measures the efficiency of electrical usage by indicating the PF. While voltmeters and ammeters provide valuable information on system performance, they don’t reveal if Q (non-working energy) is present. The PF meter fills this gap by indicating whether adjustments are needed to improve electrical efficiency.

Which power factor meter is best suited for my application?

There are analog and digital PF meters, as well as single-phase and three-phase versions. Analog meters are simple but less precise, while digital meters offer more accurate readings and often additional features, such as data logging and remote monitoring. For industrial applications with large three-phase systems, a three-phase digital PF meter is usually preferred. For smaller or simpler systems, a single-phase analog or digital meter may suffice. Learn how

Motor Power Factor impacts industrial operations, and understanding how to measure and correct it effectively is crucial.

How can a facility improve its PF after measuring it with a power factor meter?

If the power factor meter indicates a low PF, you can improve it by adding PF correction capacitors, which offset the Q in the system. Alternatively, using synchronous condensers or automatic PF correction equipment can help. Improving the PF leads to energy savings, reduced wear on equipment, and avoidance of utility company penalties for poor electrical efficiency. A Power Quality Analyzer can complement a PF meter by identifying disturbances that affect equipment performance and reliability. Using a PF meter in conjunction with an analyzer provides deeper insight into system performance.

Related Pages

Electrical Safety Requirements for Electrical Workers

Electrical safety requirements define compliance with NFPA 70E, OSHA, and IEC standards, covering arc-flash analysis, grounding and bonding, lockout/tagout, PPE selection, labeling, and maintenance procedures to mitigate electrical hazards and ensure risk control.

What Are Electrical Safety Requirements?

Electrical safety requirements are codified practices and standards to control arc-flash, shock, and fire risks.

✅ Comply with NFPA 70E, OSHA 1910 Subpart S, IEC 60364

✅ Perform arc-flash risk assessment; label incident energy

✅ Implement grounding, bonding, LOTO, and PPE programs

Electrical safety requirements are vital for reducing the risk of arc flash incidents, electrical shock, and equipment damage in industrial, commercial, and utility settings. These requirements, outlined in standards like NFPA 70E and CSA Z462, establish protocols for safe work practices, personal protective equipment (PPE), hazard assessments, and energized work procedures. Adhering to these regulations not only protects workers but also ensures compliance with occupational health and safety laws in both the United States and Canada. Understanding and implementing these electrical safety standards is essential for creating a safer, more reliable workplace. Organizations can strengthen their programs by consulting resources such as electrical safety in the workplace guidance, which provides actionable controls and documentation practices.

Complementing formal courses, arc flash safety training should cover hazard identification, approach boundaries, and hands-on PPE procedures.

In Canada, arc flash training requirements align with CSA Z462 and emphasize documented worker qualification and refresher intervals.

Request a Free Training Quotation

Electrical Safety Requirements -- Approved Materials

Only materials approved by Factory Mutual Corporation (FM) or Underwriters Laboratories (UL) should be used. Materials such as apparatus, electrical wire, equipment, and electrical wire must be used and installed as directed in the certification, labeling or listing. Using gear evaluated for arc flash protection helps ensure labels, ratings, and clearances match the system's available fault current.

Electrical Safety Requirements -- Qualified Personnel

Only workers familiar with electrical safety standards, electrical code requirements and related experience are qualified to work on electrical equipment. Defining who is qualified should follow electrical safety work principles that address training, supervision, and permitted tasks.

Pre-Work Electrical Safety Requirements

Employers are responsible for inquiring, determining and directly observing the location of any and all concealed and exposed live electrical circuits. If any electrical work requires a tool, a worker or a machine to cross set electrical safety boundaries, then the electrical circuits are to be grounded and de-energized. Before any approach, perform an assessment per NFPA 70E arc flash requirements to establish boundaries, incident energy, and safe work methods.

Electrical Safety Requirements For Underground Lines

Unless it has been de-energized, no auguring, drilling or other related practices are to be done within a six-foot parameter of any underground line. With that being said, all underground lines should be protected with longitudinal tape or surface signs.

Electrical Safety Requirements -- Job Briefings

Engineers and supervisors must provide job briefings for workers. Subsequent job briefings must also be held during the work term. These briefings must include:

- A job hazard analysis (JHA): All electrical hazards must be identified, discussed and placed in writing.

- Non-electrical hazards. In addition to electrical hazards, all other hazards must also be identified, discussed, and written down.

- Personal protective equipment (PPE): Employers are legally required to provide all workers with the necessary hard hats, rubber gloves, safety boots and other ANSI-standard-approved clothing. Arc-flash protection clothing meeting NFPA-70E standards must also be provided.

To ensure consistency, NFPA 70E training requirements recommend documenting briefing content, worker comprehension, and corrective actions.

Related Articles

Phase Rotation Meter

A phase rotation meter determines the sequence of three-phase electrical systems, ensuring correct motor connections and preventing damage to the system. It verifies phase sequence, detects wiring errors, and improves safety in industrial, commercial, and utility power applications.

What is a Phase Rotation Meter?

A phase rotation meter is an indispensable tool for industrial electricians. It ensures the correct sequence in three-phase power systems, preventing potential damage to motors, transformers, and other critical equipment.

✅ Identifies the correct sequence of three-phase power systems.

✅ Prevents motor damage by ensuring proper rotation direction.

✅ Detects wiring faults and improves system reliability.

Power System Fundamentals Training

Short Circuit Study & Protective Device Coordination Training

Arc Flash Analysis/Study Training

By understanding how to use this device, you can guarantee the safety and efficiency of your electrical installations. These systems are widely used in industrial applications because they provide a stable and efficient power supply. The term phase rotation refers to the order in which the phases of an electrical system reach their peak values. This sequence is critical for devices like motors, as it determines the direction in which they rotate. Incorrect phase rotation can result in reverse motor operation, potentially damaging equipment and halting production. A rotational phase tester is specifically designed to detect and indicate the phase sequence, ensuring that systems are installed correctly and function safely. It is a vital tool in electrical engineering, ensuring the proper phase sequence and safe operation of motors and transformers.

Functionality

The role of this meter is straightforward yet vital. By connecting its test leads to the three conductors of a system, the device measures the sequence of the electrical phases. Many modern meters display results through intuitive interfaces, making them user-friendly even for those less experienced. The ability to verify a sequence quickly and accurately minimizes downtime during installations and troubleshooting. Understanding phase rotation is closely related to load flow analysis, which evaluates power distribution and system performance.

Comparison of Phase Rotation Meters and Other Testing Devices

| Device Type | Primary Function | Advantages | Limitations |

|---|---|---|---|

| Phase Rotation Meter | Determines the three-phase sequence | Quick, accurate phase sequence detection | Limited to phase rotation checks |

| Digital Multimeter | Measures voltage, current, and resistance | Versatile, widely available | Cannot directly detect phase rotation |

| Oscilloscope | Visualizes waveforms and signal timing | Detailed phase and signal analysis | Expensive and requires technical skill |

| Clamp Meter | Measures current flow without breaking the circuit | Easy to use for current measurements | Does not indicate phase sequence |

Addressing Starting Current Challenges

A critical aspect of using equipment is managing the starting current or inrush current. This surge of electricity occurs when devices like motors or transformers are first activated, and it can trip circuit breakers if not properly managed. Understanding the relationship between phase sequence and starting current is essential for maintaining system stability. Properly using tools like devices helps mitigate issues caused by these initial electrical surges. Industrial electricians often use this device in conjunction with power system analysis and design to ensure optimal motor connections.

Frequently Asked Questions

What does it do?

It is a specialized electrical testing device used to determine the direction of the rotating magnetic field in a three-phase electrical system. It identifies the sequence in which the three phases (L1, L2, L3) are arranged, which is crucial for ensuring proper motor rotation and the safe operation of equipment. Proper rotation is crucial for motors, generators, and other rotating equipment, as incorrect rotation can lead to malfunction or mechanical damage. Proper sequence verification is a key concept in power system engineering, helping prevent costly equipment failures.

What are the common applications?

From manufacturing plants to HVAC systems, the applications of testers are vast. These devices are particularly crucial when installing or maintaining machinery reliant on three-phase power, such as industrial compressors and large-scale motors. These machines could operate inefficiently or sustain permanent damage without first confirming the rotation. Additionally, they are widely used in power distribution to verify proper connections between transformers and load equipment.

How do you calculate phase rotation?

It is not "calculated" in a mathematical sense but is rather "measured" or "determined" using a rotation meter or an oscilloscope. Here’s how you determine phase rotation:

Use a Meter:

-

Connect the three test probes of the meter to the conductors (L1, L2, L3) of the system.

-

Turn on the device.

-

The meter will display the sequence as either "ABC" (positive rotation) or "CBA" (negative rotation).

Using an Oscilloscope (Manual Method):

-

Connect the oscilloscope probes to the three phases.

-

Observe the waveform

-

The order in which the waveforms cross zero from negative to positive indicates the rotation.

-

Label the order as ABC or CBA, depending on the sequence.

How to test phase rotation with a multimeter?

A standard digital multimeter (DMM) cannot directly measure rotation, as it lacks the capability to detect the sequence. However, you can indirectly check rotation using the following method:

Identify the Phases:

- Identify the three-phase wires L1, L2, and L3.

Voltage Measurements:

- Measure the voltage between L1 and L2, L2 and L3, and L3 and L1 using the multimeter.

- Note the values. In a balanced system, the voltages should be equal.

Compare Relative Voltages:

- If you have access to two separate points (like motor terminals), turn on the motor and observe its direction of rotation.

- If the motor rotates in the opposite direction of what is intended, the rotation is incorrect, and you should swap two of the three-phase connections (like L1 and L2).

Since a multimeter cannot detect the order of the voltages, it is recommended to use a meter for this task.

How to Check the Phase Sequence with a Meter?

To check the sequence, follow these steps:

Turn Off Power: Ensure the system is de-energized before connecting the meter.

Connect the Meter Probes:

- Attach the meter's probes to the three phases (L1, L2, and L3).

- Ensure the probes are properly connected to avoid false readings.

Turn On Power:

- Energize the system.

Check the Display:

- The meter will display the sequence as either ABC (positive sequence) or CBA (negative sequence).

- Some meters have indicator lights or arrows to show the direction.

Interpret the Results:

- If the sequence is incorrect, it can be corrected by swapping two conductors (such as L1 and L2) to change the rotation.

These steps ensure the proper functioning of motors and other equipment that rely on specific rotation for normal operation.

Electricians can enhance their skills with specialized power system training, which often includes hands-on use of rotation meters and testing tools.

Related Articles

How Arc Flash Safety Training Protects Workers

Arc flash safety training prepares electricians for NFPA 70E compliance, PPE selection, hazard analysis, incident energy assessment, lockout/tagout procedures, arc-rated gear, and safe energized work practices to mitigate electrical arc hazards.

What is Arc Flash Safety Training?

Structured instruction on NFPA 70E-compliant hazard analysis, PPE, and procedures to prevent arc-flash injuries.

✅ NFPA 70E definitions, boundaries, and approach limits

✅ Incident energy analysis and arc-rated PPE selection

✅ Lockout/tagout, labeling, and energized work permits

Arc flash safety training is crucial for maintaining a safe working environment for electrical workers. It involves the implementation of necessary procedures and practices to protect workers from electrical hazards. Understanding arc flash hazards and adhering to proper safety measures, as outlined by the NFPA 70e standard for electrical safety in the workplace, significantly reduces the risk of incidents involving electrical equipment. With proper safety instruction, workers can better protect themselves and others from the potential dangers that arise during electrical work. For additional context on program fundamentals, see this electrical safety training overview for practical guidance.

Visit Our USA Workplace Electrical Safety Course

NFPA 70E Workplace Electrical Safety Course

Arc flash safety training is essential for electrical workers as they are frequently exposed to shock electrocution, arc flash, and arc blast hazards. A proper electrical safety course provides them with the knowledge and skills needed to safely handle electrical equipment and to apply safe working practices. It also ensures that workers use personal protective equipment (PPE), such as insulating tools, to reduce the risk of injury. The NFPA 70e standard requires that an electrical safety instruction program be in place to protect workers from electrical hazards, thus making the safety course mandatory in many organizations. Many organizations structure refreshers around NFPA 70E arc flash training to reinforce hazard identification.

The NFPA 70e standard for electrical safety in the workplace covers essential topics such as electrical work practices and the proper use of PPE. This standard ensures that electrical workers understand the risks associated with arc flash and electrical hazards, as well as the safety measures needed to mitigate them. These work practices include the correct procedures for operating and maintaining electrical equipment. Additionally, arc flash instruction highlights the importance of identifying hazards, creating safe work zones, and using appropriate PPE to protect against arc flash incidents. Clarifying applicability, the latest NFPA 70E arc flash requirements outline boundaries, labeling, and PPE categories for field teams.

Our CSA Z462 Arc Flash Training Course provides electrical workers with the knowledge and skills necessary to stay safe while working around electrical hazards. This course covers essential safety practices, including proper use of personal protective equipment (PPE), insulating tools, and the latest electrical safety programs. By aligning with the CSA Z462 and NFPA 70E standards, participants learn how to effectively reduce the risks of arc flash incidents and protect themselves from potential harm. Ultimately, our course helps companies enhance workplace safety, meet regulatory requirements, and protect their workforce from electrical hazards. Participants can align learning outcomes with arc flash training certification expectations to demonstrate competence.

Visit Our Canadian Workplace Electrical Safety Course:

CSA Z462 Workplace Electrical Safety Course

A well-designed electrical safety course incorporates practical elements such as the use of insulating tools, PPE, and the understanding of electrical safety programs. It also educates workers on the importance of maintaining electrical equipment and the risks associated with improper handling or maintenance. By implementing the NFPA 70e standard, employers ensure that their electrical workers are well-prepared to protect themselves from electrical hazards. In addition to this, the educational requirements outlined in the standard aim to reduce the likelihood of incidents and enhance overall workplace safety and health. Employers should verify that curricula address NFPA 70E training requirements to maintain compliance.

The importance of arc flash and electrical safety extends beyond personal protection; it ensures operational efficiency and compliance with regulatory standards. Workers must be equipped with the necessary skills to manage electrical hazards effectively, which is why organizations invest in safety instruction. Personal protective equipment plays a significant role in these programs, as it provides workers with the required protection to safely perform their duties. Ongoing competency is supported through structured NFPA 70E training that keeps procedures current.

Arc flash safety training is vital for safeguarding electrical workers from the many risks they face daily. The NFPA 70e standard for electrical safety in the workplace serves as the foundation for creating a safer work environment. By providing employees with the knowledge, equipment, and work practices necessary to handle electrical hazards, employers can protect workers and maintain a safer workplace. Establishing consistent procedures begins with clear arc flash training requirements that define frequency, content, and documentation.

Related Articles

What Is A Electrical Relay?

What Is a Electrical Relay? An electromagnetic switch that uses a coil to control contacts, enabling low-voltage control, signal isolation, switching loads, automation, and protection in power circuits across industrial, automotive, and control systems.

What Is a Electrical Relay?

An electrical relay uses a coil to actuate contacts, enabling control, isolation, and safe load switching.

✅ Electromagnetic coil actuates NO/NC contacts

✅ Isolates control circuits from high-power loads

✅ Used in PLCs, automotive, and industrial control

What Is A Electrical Relay?

An electrical relay is a crucial component in electrical engineering, which is important in controlling and protecting electrical circuits. It is classified as a switching device that operates by either opening or closing an electrical circuit. This enables them to control the flow of electrical energy to protect other equipment in the circuit and ensure safe and efficient electrical operation.

A relay, also known as a contactor, is an electronic device that switches electrical signals using an electromagnetic relay, a mechanical switch controlled by a solenoid coil. The relay contacts are essential parts that make or break the circuit connections. It consists of several parts, including a coil of wire, a common terminal, and a closed NC contact.

The working principle of a power relay is simple. When a trigger voltage energizes the coil of wire, it produces a magnetic field that moves the relay contacts. This movement can either open or close the circuit, depending on the design of the relay. Once the trigger voltage is removed, the relay contacts return to their original position. For a step-by-step overview of coil energization, contact motion, and release, see this explanation of how a relay functions for additional context.

They are vital in protecting electrical circuits from damage caused by overcurrent, short circuits, and other electrical faults. These faults can cause high current flow in the circuit, leading to equipment failure, electrical fires, and other hazards. Protective relays work with different electrical protection equipment to detect and isolate these faults before they cause damage. For foundational definitions and common features, consult this introduction to protective relays for readers new to the topic.

There are several types, including solid-state and electromagnetic relays. Solid-state units use electronic devices to switch electrical signals, while electromagnetic ones use moving parts to open and close circuit connections. For deeper design details and application tradeoffs, see this guide to solid-state relays for practical selection insights.

They can also be categorized based on their contact configuration, such as single pole single throw (SPST), single pole double throw (SPDT), double pole single throw (DPST), and double pole double throw (DPDT). These configurations refer to the number of poles and throws the relay has, determining how many circuits the relay can control.

Industrial electrical protection and control are important in protecting equipment and maintaining safe and efficient operation. They work with other electrical protection equipment to detect faults and isolate affected equipment. For example, protective relays, a type of power relay, are designed to detect specific types of faults, such as overcurrent, undercurrent, overvoltage, undervoltage, and more. For system-level practices, this overview of protective relays discusses coordination, settings, and testing routines.

They require a reliable power supply and control circuit to ensure proper operation. The control circuit provides the necessary signal to activate the relay coil, while the power supply provides the electrical energy to drive the relay coil. Therefore, when designing electrical protection schemes, it is crucial to consider the characteristics of the ones being used and their interaction with other protective devices and equipment. In complex schemes, an auxiliary relay provides extra contacts, seal-in functions, and interlocking to simplify wiring.

They can be further classified into different types based on design and function. For example, the solid-state relay is an electronic device that uses semiconductor components to switch electrical signals. It is a faster and more efficient device than an electromagnetic relay, as it has no moving parts. Conversely, the electromagnetic relay uses a solenoid coil to move the relay contacts and switch the electrical signals. Therefore, it is a more reliable device in harsh environments and is used in applications where the switching speed is not critical.

When selecting an electrical protective device, it is essential to consider the application's voltage and current rating, contact configuration, and type of load being switched. This will ensure the relay operates efficiently and safely within the electrical circuit. It is also important to consider the relay's response time, which is when the relay contacts switch from one position to another. Where intentional pickup or dropout delays are required, a time delay relay helps enforce proper sequencing and coordination.

A power relay is an essential component in industrial electrical protection and control. It operates as a switching device, using either mechanical or electronic means to open and close circuits. Protective devices work with other protective equipment to detect faults and isolate affected equipment. Power relays come in various types, configurations, and designs, and their selection and installation should be made with great care to ensure proper operation and protection of electrical equipment.

One of the crucial factors to consider when working with electrical power relays is circuit protection. Electrical circuits can be protected in various ways, such as using fuses, circuit breakers, or ground fault protection devices. Fuses and circuit breakers protect circuits from overcurrents and short circuits by opening the circuit when the current exceeds a specific threshold. Ground fault protection devices, on the other hand, detect current imbalances between the hot and neutral conductors and open the circuit when a ground fault occurs. For feeders, motors, and generators, an overcurrent relay is coordinated with upstream and downstream devices to achieve selective tripping.

Another important aspect of the operation is voltage drop. Voltage drop refers to the voltage lost as current flows through a circuit due to the resistance of the conductors. They should be selected based on the voltage drop in the circuit, as this can affect the relay's performance and ability to protect the circuit.

Electromechanical vs Microprocessor-based Electrical Power Relays

Electrical power protective devices have evolved, and there are currently two main types available on the market: electromechanical and microprocessor-based electrical power relays. While both types of relays serve the same purpose of switching electrical signals, they differ significantly in their operation, design, and functionality.

Electromechanical ones are the traditional type that has been used for many years. They use a mechanical switch controlled by a solenoid coil to switch electrical signals. When a current is applied to the solenoid coil, it creates a magnetic field that pulls the contacts together, closing the circuit. When the current is removed, the spring returns the contacts to their original position, opening the circuit. Electromechanical types are relatively simple devices that are reliable and robust. As a result, they are widely used in applications where high reliability and ruggedness are required, such as in power plants, manufacturing facilities, and other industrial settings.

On the other hand, microprocessor-based types are a more recent development in the field. They use digital technology to switch electrical signals and incorporate a microprocessor that provides advanced protection features and functionality. Microprocessor-based units, also known as digital relays, offer several advantages over electromechanical relays.

One of the significant advantages of microprocessor-based relays is their flexibility. They can be programmed to perform multiple functions, making them suitable for a wide range of applications. For example, they can be configured to operate as overcurrent, undercurrent, directional, distance, and many other types. They can also be programmed to provide advanced protection functions like fault location, event recording, and waveform capture.

Another advantage of microprocessor-based ones is their accuracy. These units can provide precise measurements of current, voltage, power, and other electrical parameters, making them ideal for applications where accuracy is critical. They can also provide fast and reliable protection against electrical faults, reducing the risk of equipment damage and downtime.

Microprocessor-based units also offer improved communications capabilities. For example, they can be connected to a network and provide remote monitoring and control, making it easier to manage electrical systems. They can also communicate with other devices, such as protective units, circuit breakers, and SCADA systems, to provide a coordinated electrical protection and control approach.

What are the different types?

There are several types, including electromechanical and microprocessor-based. Electromechanical ones are traditional devices that use a mechanical switch controlled by a solenoid coil. In contrast, microprocessor-based units use digital technology and incorporate a microprocessor that provides advanced protection features and functionality. Within these broad categories are many different types, including overcurrent, undercurrent, directional, distance, and others.

What are the applications?

Electrical power relays are used in a wide range of applications in the electrical industry. They are essential components in industrial electrical protection and control, crucial in protecting equipment and maintaining safe and efficient operation. They are used in power plants, manufacturing facilities, and other industrial settings to protect electrical systems from overcurrents, undercurrents, and other electrical faults. They can also be used in residential and commercial settings to protect circuits from overloading and short circuits.

How do you select one?

Selecting an electrical power relay depends on several factors, including the application voltage and current rating, contact configuration, response time, and voltage drop. The type of load being switched and the fault current rating of the system should also be considered. In addition, it is essential to consider the relay's characteristics, such as its operating temperature range and level of accuracy. Finally, when selecting a relay, it is important to consult the manufacturer's specifications and guidelines to ensure proper electrical circuit operation and protection.

What is the lifespan?

The lifespan of a relay depends on several factors, including the type of relay, the environment in which it operates, and the frequency of use. Electromechanical relays are generally more durable and have a longer lifespan than microprocessor-based relays. The average lifespan of a relay is typically between 10 to 20 years, but this can vary widely depending on the specific application and usage. Regular maintenance and testing can help prolong a relay's life and ensure that it continues to operate efficiently and safely.

Related Articles

How to Calculate Arc Flash Incident Energy

How to calculate arc flash incident energy? Use IEEE 1584 equations with arcing current, fault current, working distance, and clearing time per NFPA 70E to estimate PPE levels and perform electrical hazard analysis.

How to Calculate Arc Flash Incident Energy?

Apply IEEE 1584 using arcing current, distance, and clearing time per NFPA 70E to compute incident energy.

✅ Gather system data: voltage, equipment class, gap, and bolted fault current.

✅ Calculate arcing current and incident energy per IEEE 1584 equations.

✅ Use protective device clearing time and working distance; verify NFPA 70E PPE.

There are two basic standards that establish requirements for AF hazards. The first is NFPA 70E, Standard for Electrical Safety in the Workplace, which defines the basic practices to be followed for electrical safety, including personal protective equipment ppe levels which must be worn for given levels of arc flash incident energy and what steps must be taken prior to live work on electrical equipment. The second is the IEEE Guide for Performing Arc-Flash Hazard Calculations, IEEE 1584-2018 which gives the engineer the methods for calculating the severity of arc flash incident energy levels. For a deeper overview of methodologies, the guide at arc flash analysis explains how engineers apply these standards in practice today.

Request a Free Training Quotation

Visit our Arc Flash Study/Analysis Course

electricityforum.com/electrical-training/arc-flash-analysis-training

How to Calculate Arc Flash Incident Energy

In electrical systems, an AF can release dangerous amounts of energy, posing serious risks to personnel working nearby. To minimize these risks, performing an arc flash analysis is essential for assessing the potential energy and ensuring that workers are adequately protected. Calculating the arc flash incident energy is a critical step in determining the required personal protective equipment (PPE), defining safety boundaries, and minimizing the hazards of working on live electrical systems. For foundational context, see understanding arc flash calculations for how inputs translate into credible risk estimates.

What is Arc Flash Incident Energy, and Why is It Important to Calculate It?

Arc flash incident energy refers to the amount of thermal energy, measured in calories per square centimeter (cal/cm²), that a worker may be exposed to during an AF event. This energy can cause serious burns, even at relatively low levels. Calculating this energy is essential for understanding the risk level in an electrical environment and determining the appropriate PPE for workers to prevent injury. The calculation is also key in establishing the AF boundary, which defines the distance from the electrical equipment where PPE is required.

By determining the arc flash incident energy, companies can comply with standards like NFPA 70E and IEEE 1584, safeguarding workers and minimizing the risk of catastrophic injury. A concise primer on the metric is available in incident energy which clarifies units, thresholds, and typical exposure scenarios.

What Formulas or Methods Are Used to Calculate Arc Flash Incident Energy?

There are two primary methods for calculating incident energy:

-

The IEEE 1584 Method: This is the most widely used approach for conducting an analysis. IEEE 1584-2018 offers updated guidelines for more accurate calculations based on extensive testing in various conditions. The method accounts for factors such as bolted fault current, arcing time, and system configuration. The calculations are complex but provide accurate results for different equipment types and electrical configurations.

-

The Lee Method: This method, developed by Ralph Lee, is a simplified calculation for estimating incident energy in open air AF scenarios. It’s suitable for high-voltage systems and uses basic assumptions, but its simplicity makes it less accurate than the IEEE 1584 method. It’s often used as a quick reference or when detailed system data is unavailable.

Both methods are detailed in the guide for performing AFhazard calculations, providing step-by-step instructions to ensure accurate and reliable results. Engineers often benchmark results against case studies in incident energy analysis to validate model assumptions.

What Input Parameters Are Needed to Calculate Arc Flash Incident Energy?

To perform an analysis, several input parameters are required to determine the incident energy accurately. These parameters include:

- System voltage: The higher the system voltage, the greater the potential for a severe AF event.

- Fault current: This is the maximum current that can flow during a fault condition, including a bolted fault or short circuits. Higher fault currents lead to higher energy release during an electrical explosion.

- Arcing time: This is the duration of the AF, typically determined by how quickly a protective device, such as a circuit breaker, interrupts the fault. Shorter arcing times reduce the energy released.

- Working distance: This is the distance from the arc to the worker’s body. A greater working distance reduces the energy exposure and the severity of the injury.

- Equipment configuration: The size, type, and arrangement of electrical components also influence the calculation, as does whether the event occurs in open air or within an enclosure.

These parameters are critical in accurately estimating the arc flash incident energy and establishing safe work practices. These values directly influence the calculated approach distance described in arc flash boundary calculation methodologies used during labeling.

How Does the Working Distance Affect the Calculated Arc Flash Incident Energy?

The working distance — the space between the worker and the source of the arc — is a significant factor in determining the severity of the energy exposure. As the distance from the arc increases, the energy diminishes rapidly. This reduction is due to the inverse square law, where energy dissipates over distance. For example, doubling the distance from the arc can reduce the energy exposure by a factor of four. You can visualize this relationship with the arc flash calculator by varying working distance and observing the energy drop-off.

This makes it crucial to factor in the working distance when conducting an analysis. Ensuring that workers maintain a safe distance from energized components, or using remote operating tools, can significantly reduce the risk of injury from an AF event.

What Tools or Software Are Available to Help Calculate Arc Flash Incident Energy?

Given the complexity of arc flash calculations, specialized software tools and AF calculators are often used to streamline the process and ensure accuracy. These tools take into account all the necessary input parameters, including system voltage, fault current, arcing time, and equipment configuration, to provide reliable estimates of incident energy. Selecting software should align with a broader arc flash risk assessment process that prioritizes elimination and engineering controls before PPE.

These programs are built to comply with IEEE 1584-2018 and NFPA 70E, ensuring that the results meet industry standards. Additionally, they can simulate different electrical scenarios, making them invaluable for risk assessment and planning.

Calculating arc flash incident energy is an essential part of protecting workers from the hazards of AF events. The process involves multiple steps, starting with inputting critical parameters such as fault current, arcing time, and working distance. Utilizing accurate formulas like those provided in IEEE 1584-2018, combined with modern AF calculators, allows for precise and reliable results.

Understanding the importance of distance from the arc, using protective devices such as circuit breakers, and following guidelines set out by NFPA 70E are crucial for ensuring a safe work environment. With the proper tools, including software designed for analysis, organizations can confidently protect their workers and comply with electrical safety standards.

By implementing these practices and understanding the variables involved, businesses can reduce the risks of AF events and create safer electrical systems.

Related Articles

Solid State Relays - SSR Switching

Solid state relays (SSRs) provide fast, silent switching for AC or DC voltage loads using optical coupling and electrically isolated input circuits. Ideal for automation, motor control, and power supply systems, SSRs offer high reliability, energy efficiency, and long lifespan.

What are Solid State Relays?

Solid state relays utilize semiconductor components to switch electrical loads without mechanical parts, providing faster and more reliable performance than mechanical relays. They:

✅ Deliver silent, high-speed switching with no mechanical wear

✅ They are ideal for industrial automation, HVAC, and control systems

✅ Enhance reliability and lifespan in demanding applications

Basic Protection Relay Training

Request a Free Training Quotation

Solid state relays (SSR) can switch both AC or DC voltage using a low-power control signal that is completely electrically isolated from the load. The relay’s input circuits accept a specific input voltage from the power supply, which activates the switching mechanism. Through optical coupling, the SSR transfers the control signal without any physical contact, ensuring fast, silent, and reliable operation. This design makes SSRs ideal for sensitive electronics where isolation and precision are critical.

When selecting a solid state relay (SSR), it’s essential to match the input voltage and type of control signal—whether for AC or DC voltage—to the specific application. The SSR’s input circuits utilize optical coupling to maintain the control side's electrical isolation from the load side, thereby preventing interference and enhancing safety. A stable power supply ensures consistent performance, while this contactless design reduces wear and improves reliability in high-speed switching environments.

How Solid State Relays Work Compared to Electromechanical Relays

In the realm of electronics, controlling the flow of current is crucial. Traditionally, electromechanical relays (EMRs) have been the workhorses for this task. However, the rise of solid state relays has presented a compelling alternative, offering significant advantages for modern applications.

Applications of Solid State Relays

| Application Area | Example Uses | Why SSRs Are Preferred | Key Benefit |

|---|---|---|---|

| Industrial Automation | Conveyor systems, robotic arms | High-speed switching and long-term reliability | Minimal downtime in production lines |

| HVAC Systems | Heating elements, fan control | Silent and efficient operation | Energy savings and low noise |

| Motor Control | Motor speed regulation, pumps | Handles high-frequency switching (PWM) | Precise and stable motor performance |

| Medical Equipment | Imaging machines, surgical tools | Silent, surge-protected switching | Patient-friendly quiet operation |

| Audio/Recording Studios | Mixing boards, amplifiers | Noise-free switching | Preserves clean audio signals |

| LED Lighting Systems | Dimming controls, stage lighting | Fast switching for smooth dimming | Flicker-free, precise brightness control |

| Outdoor/Harsh Environments | Irrigation, chemical processing | Encapsulated design resists moisture/dust | Reliable operation in extreme conditions |

This article delves into seven key reasons why SSRs are increasingly becoming the preferred choice for various electronic systems:

High-Speed Switching and Precision Control in Modern Electronics

EMRs rely on the physical movement of contacts to switch current flow. This inherently limits their switching speed. In contrast, SSRs utilize semiconductors, allowing them to operate at extremely high speeds. Switching times for SSRs can be in the microsecond range, compared to milliseconds for EMRs. This translates to superior performance in applications requiring high-frequency control, such as:

-

-

Pulse Width Modulation (PWM): A technique for controlling power delivery by rapidly switching a circuit on and off. SSRs excel in PWM applications due to their fast switching speeds, which enable precise regulation of power output in devices such as motor controllers and LED dimmers.

-

Data Acquisition Systems: These systems involve the rapid conversion of analog signals into digital data. The high switching speed of SSRs ensures accurate signal capture and minimizes data loss during the conversion process.

-

For a detailed technical breakdown, see our guide on how a solid state relay works.

Key Applications of Solid State Relays in Industry and Technology

| Feature | Solid State Relays (SSRs) | Electromechanical Relays (EMRs) | Key Advantage of SSRs |

|---|---|---|---|

| Switching Speed | Microseconds (ideal for PWM and data systems) | Milliseconds (slower, mechanical action) | Precise high-frequency control |

| Lifespan & Reliability | Very long (no moving parts, no wear) | Limited (contact wear, arcing over time) | Minimal downtime, extended service life |

| Noise Level | Completely silent (no moving contacts) | Audible clicking during operation | Ideal for noise-sensitive environments |

| Energy Efficiency | Lower energy loss, high efficiency | Higher energy loss due to mechanical parts | Reduces costs and environmental impact |

| Environmental Resistance | Sealed design resists dust, moisture, and heat | Vulnerable to contaminants and temperature | Reliable in harsh or outdoor environments |

| Maintenance | Minimal (no contact cleaning or replacement) | Requires regular maintenance | Lowers maintenance costs |

| Signal Isolation | Built-in isolation for surge and noise protection | Limited isolation capabilities | Protects sensitive electronics |

Long-Term Reliability and Extended Lifespan of SSRs

The Achilles' heel of EMRs lies in their mechanical components. These parts are prone to wear and tear over time, leading to eventual failure. Solid state relays, devoid of moving parts, boast a significantly longer lifespan. Their solid-state design eliminates concerns about contact bounce, arcing, and mechanical fatigue, resulting in highly reliable operation for years to come. This enhanced reliability is critical in applications like:

-

-

Industrial Automation: Manufacturing processes often rely on the consistent and dependable operation of control systems. Solid state relays ensure long-term performance, minimizing downtime and production delays caused by relay failures, much like the benefits provided by advanced complex protective relays.

-

Safety-Critical Systems: In applications where equipment failure can have severe consequences, such as medical devices or emergency lighting systems, the unwavering reliability of SSRs becomes paramount—an essential feature of any robust protective relay strategy.

-

Silent Operation for Noise-Sensitive Environments

The clicking and clattering of EMRs can be a significant nuisance, particularly in noise-sensitive environments. Solid state relays operate in blissful silence due to the absence of moving parts. This silent operation makes them ideal for applications where noise control is a priority, such as:

-

-

Medical Facilities: Hospitals and clinics require a serene environment for both patients and medical personnel. SSRs contribute to a peaceful atmosphere by eliminating unwanted noise during equipment operation.

-

Audio Recording Studios: For musicians and audio engineers, capturing pristine sound recordings is paramount. The silent operation of SSRs ensures that no relay noise contaminates the delicate audio signals.

-

Energy Efficiency and Reduced Power Losses

Every watt saved translates to lower energy costs and a reduced environmental footprint. Solid state relays are inherently more efficient than EMRs. Their design minimizes energy losses during switching, leading to lower power consumption. This translates to:

-

-

Reduced Operating Costs: Businesses and individuals can benefit from lower electricity bills due to the energy-saving nature of SSRs.

-

Environmentally Friendly Operation: By consuming less power, SSRs contribute to a greener future by minimizing greenhouse gas emissions associated with electricity generation.

-

Environmental Durability and Robust Design

Dust, moisture, and extreme temperatures can significantly impact the performance of EMRs. SSRs, on the other hand, are encapsulated units that shield them from these environmental contaminants. This robust construction makes them well-suited for applications in harsh environments, such as:

-

-

Chemical Processing Plants: These facilities often involve exposure to corrosive chemicals and dust particles. The sealed construction of solid state relays protects them from these contaminants, ensuring reliable operation.

-

Outdoor Applications: Whether it's controlling lighting systems or operating irrigation equipment, SSRs can withstand the challenges of outdoor environments, including rain, snow, and extreme temperatures.

-

Low Maintenance Requirements and Cost Savings

The lack of moving parts in solid state relays eliminates the need for routine maintenance tasks, such as contact cleaning or replacement, which are essential for EMRs. This translates to:

-

-

Reduced Downtime: Since maintenance requirements are minimal, SSRs contribute to increased system uptime, minimizing production delays or disruptions in critical operations.

-

Lower Maintenance Costs: Eliminating routine maintenance tasks yields significant cost savings throughout the equipment's lifespan.

-

Signal Isolation and Surge Protection for Sensitive Equipment

Certain solid state relays offer built-in isolation between the control input and the output circuit. This isolation provides a crucial layer of protection for sensitive equipment in several ways:

-

Surge Protection: Electrical spikes and transient currents can damage delicate electronic components. The isolation barrier in SSRs helps to mitigate these surges, safeguarding connected equipment with built-in electrical surge protection.

-

Reduced Electrical Noise: Ground loops and other sources can introduce unwanted electrical noise into a system, compromising its performance. Signal isolation in SSRs helps to minimize this noise, ensuring clean and reliable signal transmission.

-

Improved System Stability: The isolation barrier helps prevent electrical interference between the control circuit and the load circuit, thereby contributing to overall system stability and enhanced performance.

Why Solid State Relays Are Replacing Mechanical Relays

Solid state relays offer a compelling alternative to electromechanical relays for a wide range of applications. Their superior speed, reliability, silent operation, efficiency, environmental resistance, and reduced maintenance requirements make them a powerful and versatile choice for modern electronic systems. Whether it's ensuring precise control in industrial automation or maintaining a peaceful environment in a medical facility, SSRs provide a reliable and efficient solution for the ever-evolving needs of the electronics industry.

Related Articles

IEP News

IEP Media

IEP Articles From ET Magazine

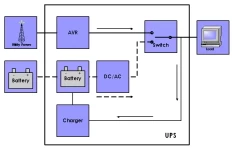

Compatibility Issues with Generator-Backed Power Systems

While both UPS systems and generators serve as safeguards against power disruptions, their integration isn't always seamless. Understanding these compatibility concerns is crucial for ensuring reliable backup power and avoiding damage to sensitive equipment.

Visit Our UPS Systems Study Course

Voltage and Frequency Stability

Generators, particularly smaller portable models, may not provide the same level of voltage and frequency stability as utility power. Line-interactive UPS units are designed to operate within a specific input voltage and frequency range. Wide fluctuations outside these tolerances can trigger the UPS to switch to battery frequently, draining reserves and potentially causing premature battery wear.

Synchronization Issues

When power from a generator is restored, there may be a phase shift or momentary mismatch in frequency compared to the UPS output. This lack of synchronization can lead to a disruptive transfer process, potentially causing a brief outage for the connected equipment.

Harmonic Distortion

Generators, especially lower-quality models or those under non-linear loads, can introduce harmonic distortion into the electrical waveform. This 'noise' in the power supply can affect the operation of sensitive electronics connected to the UPS and degrade overall power quality.

Strategies for Improved Compatibility

UPS Selection: Look for line-interactive UPS models with wider input voltage and frequency tolerance ranges. Some may offer a 'generator mode' that accommodates greater fluctuations.

Generator Quality: Whenever possible, opt for generators with better voltage regulation and lower harmonic distortion. Inverter-based generators generally provide cleaner output than conventional models.

Generator Sizing: Overloading a generator can lead to unstable output. Ensure the generator's capacity comfortably exceeds the anticipated load demand.

Isolation Transformers: In specific cases, an isolation transformer between the generator and UPS can improve compatibility by filtering out some harmonic distortion and stabilizing the voltage.

Double-Conversion UPS: A More Forgiving Solution

While the steps outlined above can improve compatibility, double-conversion online UPS systems are inherently better suited for use with generators. Here's why:

Complete Isolation: Double-conversion UPS units continuously convert incoming AC to DC and back to AC, creating a clean and regulated output regardless of generator power quality.

Wider Tolerance: These UPS systems often have wider acceptable input voltage and frequency windows, handling generator fluctuations without issue.

Considerations When Connecting a Line-Interactive UPS to a Generator

UPS Runtime: If frequent generator power deviations cause the UPS to switch to battery often, runtime will be reduced for longer outages. Assess the stability of your generator to gauge this risk.

Load Sensitivity: Less critical equipment can often tolerate generator-powered line-interactive UPS output. Highly sensitive systems might warrant a double-conversion UPS for cleaner backup power.

Neutral Bonding: Proper grounding practices are vital, especially in a generator-UPS setup. Improper neutral bonding can lead to dangerous stray currents and equipment damage.

Additional Tips

Consult Manufacturer Recommendations: Always refer to the instructions for your specific UPS and generator for guidance on compatibility and best practices.

Regular Testing: Periodically test the switchover between the generator and UPS power under load. This helps identify potential issues and ensures backup systems work as intended when needed.

Integrating line-interactive UPS systems with generators requires attention to power quality and synchronization. While choosing suitable equipment and implementing mitigation strategies improves compatibility, double-conversion UPS systems offer superior inherent resilience against generator power fluctuations. Organizations can design robust power protection schemes that ensure uninterrupted operation even during extended outages by carefully considering backup power needs and equipment sensitivity.

Line-Interactive UPS in Scalable IT Infrastructure

In the evolving landscape of IT infrastructure, reliable and flexible power solutions are paramount. Scalable line-interactive Uninterruptible Power Supply (UPS) systems provide an essential service to growing IT networks by adapting to increasing power demands without the need for complete system overhauls. This adaptability ensures that businesses can expand their IT capabilities while maintaining protection against power interruptions and fluctuations.

Visit Our UPS Systems Study Course

Scalability and Its Importance

Scalability in a UPS context refers to the ability to increase the UPS capacity to handle higher loads as demand grows. This is particularly crucial for businesses experiencing rapid growth or those planning for future expansion. The scalable nature of certain UPS systems allows for the addition of more power modules within the same infrastructure, thereby accommodating growth without significant downtime or large-scale replacements.

Advantages of Scalable UPS Systems

Cost Efficiency: Implementing a scalable UPS system is cost-effective over time. Businesses can invest in what they need today, knowing that the system can grow with their requirements. This staged investment helps manage cash flow better compared to investing in a large system upfront.

Reduced Downtime: The modular design of scalable UPS systems allows for expansions and upgrades to be performed with minimal impact on ongoing operations. This is vital for maintaining high availability and reducing the risk of downtime during upgrades.

Enhanced Flexibility: With scalable systems, IT managers can customize the UPS to meet the exact needs of their network, adjusting for power load, redundancy requirements, and runtime. This flexibility also extends to maintenance and servicing, as individual modules can be serviced or replaced without shutting down the entire system.

Long-term Reliability: Scalable UPS systems are designed to accommodate future technology changes and increases in demand. This foresight ensures that the UPS system remains reliable and effective over a longer period, thereby protecting the IT investment as the business landscape evolves.

Implementation Considerations

When planning to implement a scalable UPS system, several factors need to be considered:

Initial Assessment: Accurately assessing current power needs and future growth projections is crucial to selecting a UPS with appropriate scalability options.

Space Planning: Scalable UPS systems require strategic placement as expansions will necessitate additional space. Planning for this during the initial setup phase is essential.

Budget Allocation: While the initial cost of a scalable UPS may be higher than that of a fixed-capacity system, the long-term savings and benefits often justify the investment.

In the dynamic landscape of IT infrastructure growth, the scalability of line-interactive UPS systems presents a significant advantage. By enabling organizations to match power protection to current needs while retaining expansion capabilities for the future, scalable UPS solutions ensure reliable power, optimized investment, and minimal disruptions during inevitable periods of growth.

Scalable line-interactive UPS systems represent a smart choice for growing IT networks, offering a flexible, reliable, and cost-effective solution that grows alongside business needs. As IT infrastructure becomes increasingly critical, investing in a UPS system that can adapt to changing demands is an essential strategy for future-proofing IT operations and ensuring continuous power protection. This approach not only supports operational continuity but also aligns with the strategic growth objectives of modern businesses.

Securing Critical Infrastructure: The Role of Line-Interactive UPS

UPS (uninterruptible power supply) systems are essential for protecting critical infrastructure in healthcare and finance. They provide backup power in the event of a power outage, ensuring that sensitive equipment and data are protected. Line-interactive UPS systems are a popular choice for these applications, offering a number of advantages over other types of UPS systems.

Visit Our UPS Systems Study Course

Benefits of Line-Interactive UPS Systems

Line-interactive UPS systems offer a number of benefits over other types of UPS systems, including:

Lower cost: Line-interactive UPS systems are typically less expensive than other types of UPS systems, making them a more cost-effective option for businesses on a budget.

Smaller size: Line-interactive UPS systems are also smaller than other types of UPS systems, making them ideal for applications where space is limited.

Lower maintenance: Line-interactive UPS systems require less maintenance than other types of UPS systems, making them a more hassle-free option for businesses.

Types of Line-Interactive UPS Systems

There are two main types of line-interactive UPS systems: standby and online. Standby UPS systems only provide power when the primary power source fails, while online UPS systems provide continuous power, even during power outages.

Standby UPS systems are typically less expensive than online UPS systems, but they also offer less protection. They are a good choice for applications where the risk of a power outage is low.

Online UPS systems are more expensive than standby UPS systems, but they offer more protection. They are a good choice for applications where the risk of a power outage is high, such as hospitals and data centers.

Performance of Line-Interactive UPS Systems

The performance of a line-interactive UPS system is determined by a number of factors, including:

Power output: The power output of a UPS system is measured in VA (volt-amps). It must be sufficient to power the equipment it is protecting.

Runtime: The runtime of a UPS system is the amount of time that it can provide power during a power outage. The runtime of a UPS system is determined by the size of its battery.

Efficiency: The efficiency of a UPS system measures how much power it loses during conversion. A more efficient UPS system will lose less power and be more cost-effective to operate.

Technical Considerations

There are a number of technical considerations that must be taken into account when selecting a line-interactive UPS system, including:

Input voltage: The input voltage of a UPS system is the voltage of the power source that it is connected to. The input voltage of a UPS system must be compatible with the voltage of the power source.

Output voltage: A UPS system's output voltage is the power it supplies to its connected equipment. It must be compatible with the voltage of the equipment it is protecting.

Frequency: The frequency of a UPS system is the rate at which it converts power. The frequency of a UPS system must be compatible with the frequency of the power source.

Across the healthcare and financial sectors, where the consequences of downtime range from inconvenient to life-threatening or financially devastating, line-interactive UPS systems play a silent but vital role. Their ability to provide clean power, instant backup, and facilitate safe shutdown procedures acts as an indispensable insurance policy for critical infrastructure. As power grids evolve and technologies advance, the integration of UPS protection will remain deeply intertwined with maintaining resilience and reliable service delivery in these vital sectors.

Battery Advancements and the Impact on Line-Interactive UPS

Advancements in Battery Technology and Their Impact on Line-Interactive UPS

Line-interactive uninterruptible power supply (UPS) systems play a crucial role in ensuring power continuity for sensitive electronic equipment. Serving as a safeguard against power disruptions, these systems seamlessly switch to battery backup during outages, preventing data loss, equipment damage, and downtime. Recent advancements in battery technology, particularly lithium-ion batteries, have significantly influenced the capabilities and performance of line-interactive UPS systems.

Visit Our UPS Systems Study Course

Lithium-ion: The Emerging Choice

Lithium-ion (Li-ion) batteries, widely known for their use in laptops and electric vehicles, are increasingly finding their way into UPS systems. Here's how they stand out:

Higher Energy Density: Li-ion batteries pack more energy into a smaller and lighter form factor compared to lead-acid counterparts. This translates to space-saving UPS units or more runtime within the same footprint.

Longer Lifespan: Li-ion batteries boast more charge/discharge cycles than lead-acid batteries. This could mean less frequent battery replacements over the lifetime of the UPS system, reducing maintenance costs.

Faster Recharge Times: Li-ion batteries generally recharge faster, contributing to quicker recovery times between outages.

Efficient Operation: Reduced internal resistance leads to greater efficiency in charging and discharging, thus minimizing energy losses.

Considerations and Trade-offs

Cost: Currently, Li-ion-based UPS systems typically carry a higher initial price tag compared to those using lead-acid batteries. However, the total cost of ownership over time may be comparable or even favorable due to their longevity and lower maintenance.

Management Complexity: Li-ion batteries sometimes require more sophisticated battery management systems (BMS) for safe and optimal operation.