Tesla Q2 2020 earnings highlight resilient electric vehicles as production and deliveries outpace legacy automakers, while Gigafactory Austin advances, solar installations slump, and energy storage, Megapack, and free cash flow expand despite COVID-19 disruptions.

Key Points

Tesla posted a fourth consecutive profit, strong cash, EV resilience, solar slump, and rising energy storage.

✅ Fourth straight profit and $418M free cash flow

✅ EV output and deliveries fell just 5% year over year

✅ Solar hit record low; storage rose 61% to 419 MWh

Tesla survived the throes of the coronavirus pandemic relatively unscathed, chalking up its fourth sequential quarterly profit for the first time on Wednesday.

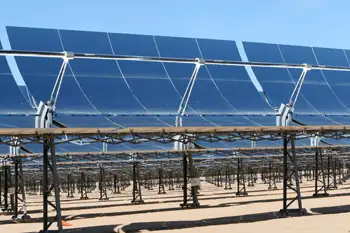

On the energy front, however, things were much more complicated: Tesla reported its worst-ever quarter for solar installations but huge growth in its battery business, amid expectations for cheaper, more powerful batteries expected in coming years. CEO Elon Musk nevertheless predicted the energy business will one day rival its car division in scale.

But today, Tesla's bottom line is all about electric vehicles, and the temporary halt of activity at Tesla's Fremont factory due to local health orders didn’t put much of a dent in vehicle production and delivery. Both figures declined 5 percent compared to the same quarter in 2019. In contrast, Q2 vehicle sales at legacy carmakers Ford, GM and Fiat Chrysler declined by one-third or more year-over-year, even as the U.S. EV market share dipped in early 2024 for context.

The costs of factory closures and a $101 million CEO award milestone for Elon Musk didn’t stop Tesla from achieving $418 million in free cash flow, a major improvement over the prior quarter. Cash and cash equivalents grew by $535 million to $8.6 billion during the quarter.

Musk praised his employees for “exceptional execution.”

“There were so many challenges, too numerous to name, but they got it done,” he said on an investor call Wednesday.

Musk also confirmed that Tesla will build a new Gigafactory in Austin, Texas, five minutes from the airport. The 2,000-acre campus will abut the Colorado River and is “basically going to be an ecological paradise,” he said. The new Texas factory will build the Cybertruck, Semi, Model 3 and Model Y for the Eastern half of North America. Fremont, California will produce the S and X, and make Model 3 and Model Y for the West, in a state where EVs exceed 20% of sales according to recent data.

Return of the Tesla solar slump

This was the first entire quarter affected by the coronavirus response, which threw the rooftop solar industry into turmoil by cutting off in-person sales. Other installers scrambled to shift to digital-first sales strategies, but Tesla had already done so months before lockdowns were imposed.

Q2, then, offers a test case on whether Tesla’s pivot to passive online sales made it better able to deal with stay-at-home orders than its peers. The other publicly traded solar installers have not yet reported their Q2 performance, but Tesla delivered its worst-ever quarterly solar figures: Installations totaled just 27 megawatts. That’s a 7 percent decline from Q2 2019, its previous worst quarter ever for solar.

Musk did not address that weak performance in his remarks to investors, opting instead to highlight the company’s late-June decision to offer the cheapest solar pricing in the country. “We’re the company to go to,” he said of rooftop solar. “It’s only going to get better later this year.”

But the sales slump indicates Tesla’s online sales model could not withstand a historically tough season for residential solar.

"Every single residential installer in the country is going to have a bad Q2 because of the initial impacts of COVID on the market," said Austin Perea, senior solar analyst at Wood Mackenzie. "It's hard to disaggregate the impacts of COVID from their own individual strategies."

Tesla's 23 percent decline in quarter-over-quarter solar installations was not as bad as the expected Q2 decline across the rooftop solar industry, Perea added.

On the vehicle side, Tesla’s sales declined less than did those of major automakers. It’s possible that the same pattern will hold for solar; a less severe drop than those seen by Sunrun or Vivint could be claimed as a victory of sorts. But this quarter made clear that Q2 2019 was not the bottom for Tesla’s solar operation, which once led the residential market as SolarCity but significantly diminished since Tesla acquired it in 2016.

Tesla currently stands in third place for residential solar installers. But No. 1 installer Sunrun said this month that it will acquire No. 2 installer Vivint Solar, making Tesla the second-largest installer by default. That major consolidation in the rooftop solar market went unremarked upon in Tesla's investor call.

Solar and energy storage revenue currently equate to just 7 percent of the company's automotive revenue. But Musk reiterated his prediction that this won’t always be the case. “Long term, Tesla Energy will be roughly the same size as Tesla Automotive,” he said on Wednesday's call.

The grid storage business offered more reason for optimism: Capacity deployed grew 61 percent from the first quarter, rising to 419 megawatt-hours. The prepackaged, large-format Megapack product turned its first profit that quarter.

"Difficult to predict" performance in the second half of 2020

Tesla withdrew its financial guidance last quarter in light of the upheaval across the global economy. It refrained from setting new guidance now.

“Although we have successfully ramped vehicle production back to prior levels, it remains difficult to predict whether there will be further operational interruptions or how global consumer sentiment will evolve, given risks to the EV boom noted by analysts, in the second half of 2020,” the earnings report notes.

The company asserted it will still deliver 500,000 vehicles this year regardless of externalities, a goal that aligns with broader EV sales momentum in 2024 trends. It already has sufficient production capacity installed to reach that, Tesla said. But with 179,387 cars delivered so far, Tesla faces an uphill climb to ship more cars in the second half.

Wall Street maintained its buoyant confidence in Tesla's share price, despite rising competition in China noted by rivals. It closed at $1,592 before the earnings announcement, rising to $1,661 in after-hours trading.

Related News