Industrial Electrical Power

Uninterruptible Power Supply

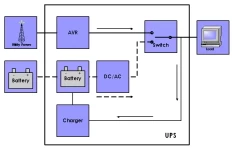

Uninterruptible power supply (UPS) delivers battery backup, surge protection, voltage regulation, and power conditioning to keep servers, networks, and critical equipment running during outages, with online and line-interactive inverter designs.

What Is an Uninterruptible Power Supply (UPS)?

An Uninterruptible power supply delivers battery backup, surge protection, and voltage regulation to prevent downtime.

✅ Protects servers and networking gear from power loss

✅ Provides AVR for brownouts, sags, and surges

✅ Offers online or line-interactive inverter topologies

An uninterruptible power supply is an essential component of modern life, providing emergency backup, electrical protection, and voltage regulation for a wide range of applications. From safeguarding sensitive equipment like single-phase networking devices and preventing data loss to ensuring the smooth operation of life-saving devices, UPS systems play a crucial role in maintaining the reliability of electrical supply. By understanding the different types of UPS systems, their features, and their applications, one can make an informed decision when selecting the right UPS system for their specific needs. For a concise primer, the basics of UPS systems explain core concepts for new buyers.

A UPS system offers several benefits beyond providing backup during an outage. One of its essential functions is power protection, ensuring that electrical equipment remains safe from surges, voltage fluctuations, and other electricity-related issues. Surge protection plays a critical role in this aspect by safeguarding connected devices from sudden voltage spikes, which could cause irreversible damage. These protective roles are described in the context of a UPS power supply and how it stabilizes connected loads.

Voltage regulation is another vital aspect of uninterruptible power supplies. It helps maintain a constant voltage level for the connected equipment, especially during voltage fluctuations. This feature is essential for the smooth operation of sensitive equipment like computers, networking equipment, and medical devices.

UPS systems come in various types, such as single-phase and three-phase, based on the electrical load they can handle. The most common types are line-interactive, double conversion, and standby. Line-interactive UPS systems adjust the input voltage with the help of an autotransformer, while double conversion systems convert the input AC power to DC and then back to AC, providing a pure sine wave output. Standby UPS systems, on the other hand, only switch to battery during an outage. A helpful overview of uninterruptible power supply architectures clarifies how these modes differ in practice.

The heart of any UPS system is its battery backup, which provides emergency supply when the main source fails. These batteries store electrical energy and release it during outages or fluctuations. The battery's run time is a crucial factor to consider when selecting a UPS, as it determines how long the connected devices can continue to operate on backup supply. For planning runtime, this battery backup guide outlines sizing and replacement intervals.

Another aspect to consider when selecting a UPS system is the volt-ampere (VA) rating, which indicates the maximum electrical load the UPS can handle. It is essential to choose a UPS with a VA rating that matches the electricity requirements of the equipment it will protect. A detailed checklist in the UPS selection guide helps match VA and wattage to your load.

Uninterruptible power supplies are indispensable for a wide range of applications, from residential use to large-scale industrial setups. For example, in homes, a UPS can provide backup supply to essential appliances and devices during an outage, ensuring safety and comfort. In businesses, UPS systems protect sensitive equipment like servers and networking devices from power-related damage, preventing data loss and ensuring business continuity.

In mission-critical facilities like hospitals, uninterruptible power supplies play a vital role in providing emergency supply to life-saving equipment and maintaining essential operations during failures. Similarly, UPS systems are critical in data centers, where they protect against data loss and downtime caused by disruptions.

Surge protectors are often used in conjunction with UPS systems to provide an additional layer of protection. While a UPS safeguards against outages and voltage fluctuations, surge protectors protect connected devices from voltage spikes caused by lightning strikes or other electrical disturbances. It is also important to understand potential hazards, and this review of UPS risks explains common pitfalls and mitigation steps.

To ensure optimal performance, it is essential to select the right UPS system for your specific needs. Factors to consider include the type of equipment you need to protect, the required run time, and the appropriate VA rating. Additionally, it is essential to keep in mind that some devices, like sensitive equipment and devices with motors, may require a UPS with a pure sine wave output.

Regular maintenance is crucial for the longevity and performance of a UPS system. This includes periodically checking and replacing batteries, as well as monitoring the overall health of the system. Proper maintenance ensures that your uninterruptible power supply remains ready to provide backup power and protection when needed.

What are the different types of UPS systems, and how do they differ in functionality?

There are three main types of UPS systems:

- Standby (offline) UPS: This type of UPS remains idle until a disruption occurs. When the main supply fails, it switches to battery to provide backup. Standby UPS systems are the most basic and cost-effective option, suitable for smaller applications like home computers.

- Line-interactive UPS: This type of UPS actively regulates voltage by using a built-in transformer that adjusts input voltage to maintain a consistent output voltage. When am electrical outage occurs, it switches to battery supply. Line-interactive UPS systems are suitable for small businesses and office environments, providing protection against voltage fluctuations and outages.

- Online (double-conversion) UPS: This type of UPS continuously converts incoming AC to DC and then back to AC, providing a pure sine wave output. It offers the highest level of electrical protection, isolating connected equipment from power disturbances. Online UPS systems are ideal for mission-critical applications, such as data centers and medical facilities, where consistent and clean power is essential.

How do I choose the right UPS system for my specific needs and equipment?

To choose the right UPS system, consider the following factors:

- Application: Determine whether you need a UPS for home, office, or industrial use, and choose the appropriate type (standby, line-interactive, or online) accordingly.

- Power requirements: Calculate the total electricity consumption of your equipment, and select a UPS with a sufficient capacity (measured in volt-amperes or watts) to handle the load.

- Runtime: Determine how long you need the UPS to provide backup electricity in the event of an outage, and choose a system with a suitable battery capacity.

- Voltage regulation and surge protection: Ensure the UPS provides the necessary level of voltage regulation and surge protection for your sensitive equipment.

What factors should I consider when determining the appropriate size and capacity of a UPS system?

Consider the following factors:

- Power consumption: Calculate the total electricity consumption of the connected equipment (in watts or volt-amperes).

- Runtime: Determine the desired runtime during an outage.

- Expansion: Consider any potential future equipment additions that may increase electricity requirements.

- Efficiency and redundancy: Account for UPS efficiency and, if needed, additional capacity for redundancy.

For organizations focused on lowering energy and cooling costs, a high efficiency UPS system can deliver meaningful savings without sacrificing protection.

How can a UPS system help protect my sensitive electronic equipment from electricity issues like power surges, outages, and voltage fluctuations?

A UPS system provides protection against electricity issues by:

- Supplying backup electricity during outages, preventing data loss and equipment shutdown.

- Regulating voltage to maintain a consistent output, protecting equipment from voltage fluctuations.

- Providing surge protection to shield connected devices from voltage spikes that can cause damage.

What is the importance of regular maintenance and battery replacement for UPS systems?

- Regular maintenance and battery power replacement are essential for:

- Ensuring optimal performance and efficiency of the UPS system.

- Prolonging the lifespan of the UPS and preventing premature failure.

- Maintaining consistent backup electricity availability during outages.

- Ensuring the safety and reliability of the UPS system and connected equipment.

How can a UPS system benefit various industries and applications, such as data centers, healthcare facilities, and residential use?

- Data centers: UPS protects against data loss and downtime, ensuring business continuity and safeguarding critical IT infrastructure.

- Healthcare facilities: UPS provides emergency electricity to life-saving equipment and essential systems, maintaining patient safety and care during electricity disruptions.

- Residential use: UPS protects home electronics from electricity disturbances and provide backup power during outages, ensuring safety, comfort, and the continued operation of essential devices.

Related Articles

Test Your Knowledge About Electrical Transformers!

Think you know Electrical Transformers? Take our quick, interactive quiz and test your knowledge in minutes.

- Instantly see your results and score

- Identify strengths and areas for improvement

- Challenge yourself on real-world electrical topics

Latest IEP Content

What Is A Electrical Relay?

What Is a Electrical Relay? An electromagnetic switch that uses a coil to control contacts, enabling low-voltage control, signal isolation, switching loads, automation, and protection in power circuits across industrial, automotive, and control systems.

What Is a Electrical Relay?

An electrical relay uses a coil to actuate contacts, enabling control, isolation, and safe load switching.

✅ Electromagnetic coil actuates NO/NC contacts

✅ Isolates control circuits from high-power loads

✅ Used in PLCs, automotive, and industrial control

What Is A Electrical Relay?

An electrical relay is a crucial component in electrical engineering, which is important in controlling and protecting electrical circuits. It is classified as a switching device that operates by either opening or closing an electrical circuit. This enables them to control the flow of electrical energy to protect other equipment in the circuit and ensure safe and efficient electrical operation.

A relay, also known as a contactor, is an electronic device that switches electrical signals using an electromagnetic relay, a mechanical switch controlled by a solenoid coil. The relay contacts are essential parts that make or break the circuit connections. It consists of several parts, including a coil of wire, a common terminal, and a closed NC contact.

The working principle of a power relay is simple. When a trigger voltage energizes the coil of wire, it produces a magnetic field that moves the relay contacts. This movement can either open or close the circuit, depending on the design of the relay. Once the trigger voltage is removed, the relay contacts return to their original position. For a step-by-step overview of coil energization, contact motion, and release, see this explanation of how a relay functions for additional context.

They are vital in protecting electrical circuits from damage caused by overcurrent, short circuits, and other electrical faults. These faults can cause high current flow in the circuit, leading to equipment failure, electrical fires, and other hazards. Protective relays work with different electrical protection equipment to detect and isolate these faults before they cause damage. For foundational definitions and common features, consult this introduction to protective relays for readers new to the topic.

There are several types, including solid-state and electromagnetic relays. Solid-state units use electronic devices to switch electrical signals, while electromagnetic ones use moving parts to open and close circuit connections. For deeper design details and application tradeoffs, see this guide to solid-state relays for practical selection insights.

They can also be categorized based on their contact configuration, such as single pole single throw (SPST), single pole double throw (SPDT), double pole single throw (DPST), and double pole double throw (DPDT). These configurations refer to the number of poles and throws the relay has, determining how many circuits the relay can control.

Industrial electrical protection and control are important in protecting equipment and maintaining safe and efficient operation. They work with other electrical protection equipment to detect faults and isolate affected equipment. For example, protective relays, a type of power relay, are designed to detect specific types of faults, such as overcurrent, undercurrent, overvoltage, undervoltage, and more. For system-level practices, this overview of protective relays discusses coordination, settings, and testing routines.

They require a reliable power supply and control circuit to ensure proper operation. The control circuit provides the necessary signal to activate the relay coil, while the power supply provides the electrical energy to drive the relay coil. Therefore, when designing electrical protection schemes, it is crucial to consider the characteristics of the ones being used and their interaction with other protective devices and equipment. In complex schemes, an auxiliary relay provides extra contacts, seal-in functions, and interlocking to simplify wiring.

They can be further classified into different types based on design and function. For example, the solid-state relay is an electronic device that uses semiconductor components to switch electrical signals. It is a faster and more efficient device than an electromagnetic relay, as it has no moving parts. Conversely, the electromagnetic relay uses a solenoid coil to move the relay contacts and switch the electrical signals. Therefore, it is a more reliable device in harsh environments and is used in applications where the switching speed is not critical.

When selecting an electrical protective device, it is essential to consider the application's voltage and current rating, contact configuration, and type of load being switched. This will ensure the relay operates efficiently and safely within the electrical circuit. It is also important to consider the relay's response time, which is when the relay contacts switch from one position to another. Where intentional pickup or dropout delays are required, a time delay relay helps enforce proper sequencing and coordination.

A power relay is an essential component in industrial electrical protection and control. It operates as a switching device, using either mechanical or electronic means to open and close circuits. Protective devices work with other protective equipment to detect faults and isolate affected equipment. Power relays come in various types, configurations, and designs, and their selection and installation should be made with great care to ensure proper operation and protection of electrical equipment.

One of the crucial factors to consider when working with electrical power relays is circuit protection. Electrical circuits can be protected in various ways, such as using fuses, circuit breakers, or ground fault protection devices. Fuses and circuit breakers protect circuits from overcurrents and short circuits by opening the circuit when the current exceeds a specific threshold. Ground fault protection devices, on the other hand, detect current imbalances between the hot and neutral conductors and open the circuit when a ground fault occurs. For feeders, motors, and generators, an overcurrent relay is coordinated with upstream and downstream devices to achieve selective tripping.

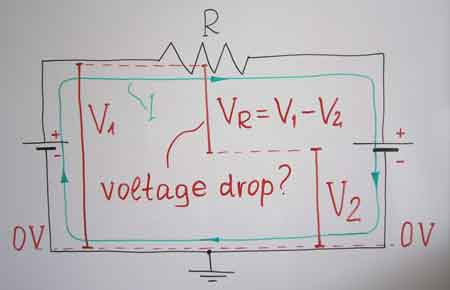

Another important aspect of the operation is voltage drop. Voltage drop refers to the voltage lost as current flows through a circuit due to the resistance of the conductors. They should be selected based on the voltage drop in the circuit, as this can affect the relay's performance and ability to protect the circuit.

Electromechanical vs Microprocessor-based Electrical Power Relays

Electrical power protective devices have evolved, and there are currently two main types available on the market: electromechanical and microprocessor-based electrical power relays. While both types of relays serve the same purpose of switching electrical signals, they differ significantly in their operation, design, and functionality.

Electromechanical ones are the traditional type that has been used for many years. They use a mechanical switch controlled by a solenoid coil to switch electrical signals. When a current is applied to the solenoid coil, it creates a magnetic field that pulls the contacts together, closing the circuit. When the current is removed, the spring returns the contacts to their original position, opening the circuit. Electromechanical types are relatively simple devices that are reliable and robust. As a result, they are widely used in applications where high reliability and ruggedness are required, such as in power plants, manufacturing facilities, and other industrial settings.

On the other hand, microprocessor-based types are a more recent development in the field. They use digital technology to switch electrical signals and incorporate a microprocessor that provides advanced protection features and functionality. Microprocessor-based units, also known as digital relays, offer several advantages over electromechanical relays.

One of the significant advantages of microprocessor-based relays is their flexibility. They can be programmed to perform multiple functions, making them suitable for a wide range of applications. For example, they can be configured to operate as overcurrent, undercurrent, directional, distance, and many other types. They can also be programmed to provide advanced protection functions like fault location, event recording, and waveform capture.

Another advantage of microprocessor-based ones is their accuracy. These units can provide precise measurements of current, voltage, power, and other electrical parameters, making them ideal for applications where accuracy is critical. They can also provide fast and reliable protection against electrical faults, reducing the risk of equipment damage and downtime.

Microprocessor-based units also offer improved communications capabilities. For example, they can be connected to a network and provide remote monitoring and control, making it easier to manage electrical systems. They can also communicate with other devices, such as protective units, circuit breakers, and SCADA systems, to provide a coordinated electrical protection and control approach.

What are the different types?

There are several types, including electromechanical and microprocessor-based. Electromechanical ones are traditional devices that use a mechanical switch controlled by a solenoid coil. In contrast, microprocessor-based units use digital technology and incorporate a microprocessor that provides advanced protection features and functionality. Within these broad categories are many different types, including overcurrent, undercurrent, directional, distance, and others.

What are the applications?

Electrical power relays are used in a wide range of applications in the electrical industry. They are essential components in industrial electrical protection and control, crucial in protecting equipment and maintaining safe and efficient operation. They are used in power plants, manufacturing facilities, and other industrial settings to protect electrical systems from overcurrents, undercurrents, and other electrical faults. They can also be used in residential and commercial settings to protect circuits from overloading and short circuits.

How do you select one?

Selecting an electrical power relay depends on several factors, including the application voltage and current rating, contact configuration, response time, and voltage drop. The type of load being switched and the fault current rating of the system should also be considered. In addition, it is essential to consider the relay's characteristics, such as its operating temperature range and level of accuracy. Finally, when selecting a relay, it is important to consult the manufacturer's specifications and guidelines to ensure proper electrical circuit operation and protection.

What is the lifespan?

The lifespan of a relay depends on several factors, including the type of relay, the environment in which it operates, and the frequency of use. Electromechanical relays are generally more durable and have a longer lifespan than microprocessor-based relays. The average lifespan of a relay is typically between 10 to 20 years, but this can vary widely depending on the specific application and usage. Regular maintenance and testing can help prolong a relay's life and ensure that it continues to operate efficiently and safely.

Related Articles

What Determines the Severity of Injury in Arc Flash

What determines the severity of injury in arc flash? Incident energy depends on fault current, arc duration (clearing time), working distance, voltage, electrode configuration, enclosure effects, and PPE per NFPA 70E and IEEE 1584.

What Determines the Severity of Injury in Arc Flash?

Severity is set by incident energy from fault current, clearing time, distance, voltage, and setup.

✅ Higher fault current increases incident energy and burn severity.

✅ Longer clearing time extends arc duration and heat exposure.

✅ Shorter working distance magnifies energy at the worker.

Determining the Severity of Injury in Arc Flash

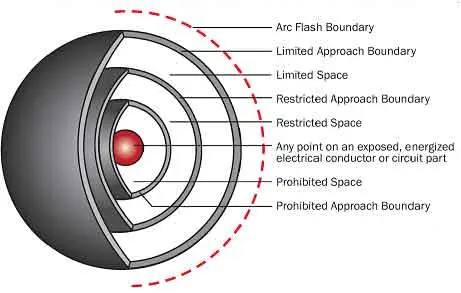

The severity of injury in an arc flash depends on incident energy, working distance, and protective device performance. Higher energy exposure and closer proximity increase the risk of burns, trauma, and fatal injuries. For foundational definitions of hazard categories and energy thresholds, the Arc Flash Hazard overview provides context for interpreting severity assessments.

Another crucial factor is the working distance, which is the distance between the worker and the source of the electrical arc. The closer a person is to the arc, the higher the energy exposure, leading to more severe injuries. Properly performing an arc flash analysis can help determine the potential incident energy and establish safe working distances. To understand initiating mechanisms that elevate risk at close range, the causes of arc flash resource explains fault types, equipment conditions, and human factors.

Intensity of an Arc Flash

Several factors, including the electrical system parameters, such as voltage and fault current, influence an arc flash's intensity. The presence of protective devices, like circuit breakers and fuses, also plays a significant role in controlling the intensity by interrupting the fault quickly. For situational examples that tie parameters to real-world events, see when an arc flash is likely to occur for context on operating states and tasks.

Moreover, the condition and maintenance of electrical equipment are critical. Well-maintained equipment is less likely to experience faults that can lead to severe arc flash incidents. An arc flash risk assessment, as outlined in NFPA 70E, helps identify and mitigate potential hazards within an electrical system. For a structured approach to evaluating those conditions, the arc flash risk assessment guide details data collection, modeling, and control selection.

Biggest Factor Contributing to Severity

The incident energy level is the biggest factor contributing to the severity of an arc flash. Higher levels of incident energy result in more intense arcs, leading to severe burns and other injuries. Effective electrical safety programs, including regular maintenance and proper use of protective devices, can help manage and reduce incident energy levels. Practical mitigation tactics in the arc flash protection guide cover engineering controls, labeling strategies, and PPE integration.

Factors in Arc Flash Risk Assessment

An arc flash risk assessment involves evaluating three main factors:

-

Incident Energy: Calculating the potential energy release to determine appropriate personal protective equipment (PPE) requirements and safe work practices.

-

Working Distance: Establishing safe boundaries to minimize exposure to high-energy arcs. The arc flash boundary is a critical parameter in defining safe working zones.

-

Protective Devices: Ensuring that circuit breakers, fuses, and other protective devices are properly rated and maintained to interrupt faults and reduce the duration of an arc quickly.

Importance of Personal Protective Equipment (PPE)

Personal protective equipment (PPE) is essential in protecting workers from the hazards of an electrical arc. The appropriate arc flash PPE category must be selected based on the incident energy levels identified during the risk assessment. Proper PPE, including flame-resistant clothing, face shields, and gloves, can significantly reduce the severity of injuries.

For evidence on injury patterns and treatment considerations, the arc flash injuries reference summarizes burn types, trauma mechanisms, and recovery implications.

Several key factors, including incident energy, working distance, and the condition of electrical equipment, determine the severity of injuries in an arc flash incident. Performing a thorough arc flash analysis and risk assessment guided by NFPA 70E is essential in identifying and mitigating these risks. Understanding the factors that influence the intensity and severity of an arc flash and implementing proper electrical safety measures and PPE can significantly reduce the risks associated with arc flash incidents.

This article has highlighted the critical elements determining the severity of injuries in an arc flash and the importance of comprehensive risk assessments and appropriate safety measures. By focusing on these areas, we can enhance the safety of electrical systems and protect workers from the severe consequences of arc flash incidents. Real-world perspectives from the arc flash victim profiles can reinforce training and hazard awareness across teams.

Related Resources

Related Articles

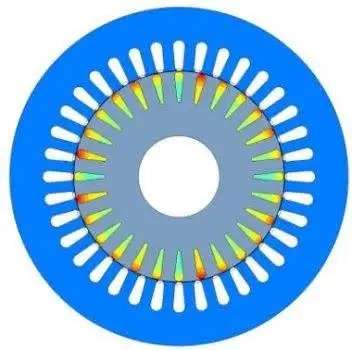

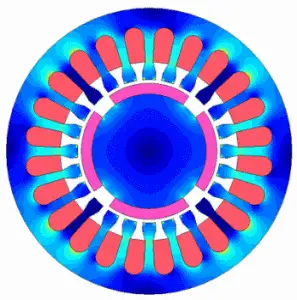

Current Transformer Simulation

Current transformer simulation models how CTs behave under electrical load, helping engineers test system performance, accuracy, and safety. It’s vital for power system design, fault analysis, and protective relay coordination.

What is Current Transformer Simulation?

Current transformer simulation is the virtual modelling of CT behaviour in electrical systems.

✅ Accurately predicts CT performance under various load and fault conditions

✅ Helps design, test, and validate protective relay systems

✅ Enhances power system safety, measurement, and fault analysis

Current transformer simulation is critical for industrial electricians, as it allows for accurate analysis and troubleshooting of electrical systems without disrupting operations. Understanding how to simulate devices ensures system reliability, optimizes power distribution, and upholds safety standards in complex industrial environments. This article explores the principles of simulation, its practical applications, and best practices for using simulation tools effectively—empowering you to tackle electrical challenges with confidence. Understanding the function of a transformer is fundamental before diving into how CT simulations model electrical behavior in complex power systems.

Electrical Transformer Maintenance Training

Substation Maintenance Training

Request a Free Training Quotation

The Role of Simulation Software and Tools

Accurate current transformer simulation has become essential for engineers and designers working with power systems. These simulations provide valuable insights into how CTs operate under different conditions, helping optimize their performance and ensure real-world reliability. By combining advanced software tools with precise modeling techniques, engineers can predict device behavior more accurately. In real-world applications, especially in substations, electrical substation transformers play a critical role, and simulating their CTs helps ensure fault detection and relay protection accuracy.

For example, when simulating a high-voltage transformer in a power plant, engineers can anticipate how it will respond during peak load hours and adjust parameters to prevent unexpected failures. This proactive approach saves time, prevents downtime, and enhances system reliability.

Current Transformer Simulation – Comparison Table

| Feature | Real CT Testing | Software-Based Simulation | Hardware-in-the-Loop (HIL) Simulation |

|---|---|---|---|

| Purpose | Validates physical CT performance | Models CT behavior in virtual systems | Combines real-time CT data with digital simulation |

| Accuracy | High (actual measurements) | High, but depends on model fidelity | Very high with real-time data feedback |

| Cost | Expensive (equipment, setup) | Low to moderate | High (specialized equipment required) |

| Safety | Involves high-voltage risks | Completely safe | Safe but requires interface isolation |

| Flexibility | Limited to available CT types | Highly flexible (any rating or class) | Flexible, but constrained by hardware interfaces |

| Time Efficiency | Time-consuming setup and testing | Fast simulations with repeatable conditions | Moderate, real-time capable but setup-intensive |

| Use in Relay Coordination | Manual testing with actual CTs | Simulates relay response accurately | Real-time dynamic testing with actual relays |

| System Fault Analysis | Limited to historical or lab conditions | Models various fault scenarios and load flows | Real-time fault injection and CT reaction monitoring |

| Training & Education | Less practical for classrooms | Ideal for training and learning environments | Suitable for advanced engineering education |

Understanding Core Saturation Effects

Core saturation is a crucial phenomenon in operation. When a CT’s magnetic core becomes saturated, its ability to transform current accurately diminishes, leading to distorted outputs and potentially compromising protective systems. This issue is especially common during fault conditions or high-load scenarios.

To illustrate, imagine a manufacturing plant experiencing a short circuit. If the CT’s core becomes saturated, the protective relays may receive incorrect readings, delaying their response. Simulating core saturation allows engineers to predict these issues and design CTs that can withstand extreme conditions. CT simulations are especially valuable when working with high-voltage transformers, where performance under stress must be precisely analyzed without risking actual equipment.

Ensuring Accuracy Through Error Analysis

Another critical aspect of CT simulation is ensuring accuracy. Discrepancies between simulation results and real-world performance can lead to inefficiencies or even failures in applications where precision is non-negotiable.

Error analysis plays a key role here. By comparing simulated data with experimental results, engineers can identify potential sources of error, such as inaccurate material properties or overlooked nonlinearities. This process improves modeling techniques and ensures that simulations remain a reliable tool for guiding system design. Engineers designing CTs also benefit from understanding key physical components, like the transformer core, since core properties directly affect saturation and modeling accuracy.

Practical Applications and Troubleshooting

Current transformer simulation goes beyond design—it plays a vital role in troubleshooting and system optimization. For instance, in renewable energy systems, CT simulations help fine-tune the integration of solar and wind energy into existing grids. In industrial facilities, simulations can diagnose issues like insulation breakdown, overvoltage conditions, and overheating before they escalate into costly problems.

One real-world example involves identifying thermal inefficiencies in an industrial substation. By simulating different load conditions, engineers can pinpoint areas where excessive heat builds up and adjust the system to improve cooling and prevent equipment failure. For effective CT testing in the field, condition data from maintenance inspection windows on transformers can validate simulation results and improve long-term reliability.

Beyond the Design Phase

The benefits of simulation extend well beyond initial design. In metering applications, simulations help ensure that CTs provide precise readings, even when load conditions fluctuate throughout the day. In protective systems, accurate simulations prevent malfunctions by ensuring relays receive correct input signals, minimizing false trips or failures to respond during emergencies.

This versatility demonstrates how simulation supports both innovation and day-to-day operational excellence, making it an indispensable tool in modern electrical engineering.

Frequently Asked Questions

How can I simulate a CT in MATLAB or Simulink?

To simulate a CT in MATLAB or Simulink, you need to model its core and windings accurately. Use coupled inductors or mutual inductance blocks to represent the primary and secondary windings, specifying parameters such as the turns ratio and impedance. Magnetic core properties—such as permeability, cross-sectional area, and core length—should also be defined. Include nonlinear effects like core saturation and hysteresis using lookup tables or built-in Simscape components. Don’t forget to model the secondary load impedance, as this affects the CT’s performance.

What parameters are critical for accurate current transformer simulation?

Critical parameters include the turns ratio, core permeability, core area, and saturation flux density. Other key factors are winding resistance, leakage inductance, and the coupling coefficient. The burden (load impedance) connected to the secondary side must be accounted for, as it influences accuracy. Additionally, consider the CT’s frequency response and excitation current, which accounts for core losses.

How does core saturation affect a CT?

Core saturation occurs when the magnetic core reaches its flux density limit, causing nonlinear behavior. This results in distorted outputs and can impact protective systems. Simulations capture this effect using the B-H curve, which relates magnetic flux to field intensity. You can use Simscape blocks or custom MATLAB equations to represent these nonlinearities.

What are the common challenges in CT simulation?

Common challenges include failing to account for nonlinearities such as saturation and hysteresis, using incorrect parameter estimates, and misrepresenting the secondary burden impedance. Numerical instabilities can also arise from poor solver configurations or time step sizes. Additionally, neglecting frequency-dependent effects like eddy currents can compromise the accuracy of the simulation.

How do I validate a CT simulation against real-world data?

To validate a simulation, compare its results with manufacturer-provided specifications for ratio error, phase angle error, and saturation characteristics. Laboratory tests using controlled sinusoidal and transient inputs can also confirm accuracy. Comparing the transient response during fault scenarios helps ensure the model aligns with real-world behavior. Field measurements from actual installations serve as a practical benchmark for confirming simulation fidelity.

Current transformer simulation is a multidimensional process that combines advanced software, meticulous modeling, and real-world validation. By leveraging these tools, engineers can design CTs that exceed performance expectations and contribute to the efficiency and stability of modern power systems. As simulation technologies evolve, the potential for innovation in CT design and application will only grow, paving the way for more reliable and sustainable energy solutions.

Related Articles

How can I mark off arc flash boundaries?

How can I mark off arc flash boundaries? Follow NFPA 70E and IEEE 1584, calculate incident energy, set approach limits, apply labels, post warning signs, and install barricades with required PPE distances.

How Can I Mark Off Arc Flash Boundaries?

Use NFPA 70E/IEEE 1584 to calculate energy, set limits, label, and barricade.

✅ Perform an arc flash study per IEEE 1584 to determine boundaries.

✅ Label equipment with incident energy, voltage, and PPE categories.

✅ Deploy barriers and signage; control access per NFPA 70E.

To mark off an arc flash boundary, calculate the distance at which incident energy drops to 1.2 cal/cm² using NFPA 70E or IEEE 1584 formulas. Once calculated, physically mark the perimeter with signage, floor tape, or barriers to alert personnel of the restricted area. For a step-by-step example of applying these formulas, see our Arc Flash Boundary Calculation guide for practical setup tips.

An arc flash boundary is a safety perimeter set around electrical equipment to protect individuals from the potential harm of an arc flash. The boundary is defined as the distance from the equipment where the energy released during an arc flash drops to 1.2 cal/cm², a level that can cause second-degree burns. Determining this boundary is a critical task typically performed by an electrical engineer. Here’s an overview of how these boundaries are calculated. A concise primer on key definitions is available in our Arc Flash Boundary overview to help teams align terminology.

Request a Free Training Quotation

Steps to Calculate the Arc Flash Boundary

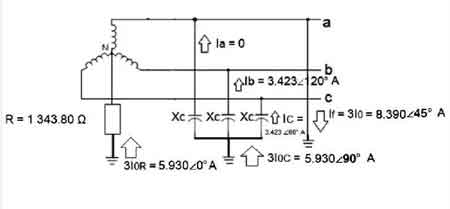

The calculation of an arc flash boundary depends primarily on the voltage of the equipment involved. The calculation methods differ between AC and DC systems, so it is essential to have accurate system information.

Using Software for Calculation

Many companies utilize specialized software to calculate arc flash boundaries. These programs allow users to input voltage and other relevant data about the equipment. The software then processes this information to determine the arc flash boundary accurately, providing critical data for setting safety distances within a facility. If you're new to the inputs and assumptions these tools use, review Understanding Arc Flash Calculations to validate your model choices.

Manual Calculation Methods

For businesses without access to such software or those seeking to verify results manually, there are two main methodologies for calculating the boundary. When comparing results, a quick check against a boundary table by incident energy can flag outliers.

-

NFPA 70E Formula: The NFPA 70E standard provides a formula to calculate the incident energy of equipment. This formula considers factors such as voltage, current, and distance to establish the arc flash boundary. For context on how this relates to shock protection thresholds, see how arc flash and electric shock protection boundaries are determined for integrated planning.

-

IEEE 1584 Formula: This method uses empirically-based formulas derived from extensive laboratory testing. IEEE 1584 is often regarded as more accurate due to its comprehensive data and refined calculations. You can visualize typical distances using an arc flash boundary chart to support field briefings.

Importance of Accurate Data

Regardless of the method used—whether software or manual calculations—accuracy in input data is paramount. Incorrect voltage or system information will lead to inaccurate boundary determinations, putting employees and facilities at risk. Ensuring precise and verified data entry is crucial for establishing effective and reliable arc flash boundaries.

Maintaining Safety with Arc Flash Boundaries

Establishing and adhering to arc flash boundaries is essential for workplace safety. These boundaries help to protect individuals from severe burns and other injuries caused by arc flashes. Properly determined boundaries also contribute to the overall safety protocol of a facility, ensuring that all personnel are aware of and respect the safe distances around electrical equipment. For foundational information on arc flash boundaries, visit our Arc Flash Boundary section.

Determining arc flash boundaries involves understanding the equipment's voltage, utilizing accurate calculation methods, and ensuring precise data entry. Whether through advanced software or manual calculations using NFPA 70E or IEEE 1584 formulas, the goal is to establish a safe perimeter that protects individuals from the dangers of arc flashes. For example scenarios, many practitioners reference the boundary for 8 cal/cm² when selecting PPE categories.

Related Resources

Related Articles

High Resistance Grounding

High resistance grounding limits fault current to a low level in electrical systems, reducing arc flash hazards and equipment damage. It enhances system reliability, safety, and uptime in industrial power distribution networks.

What is High Resistance Grounding?

High resistance grounding (HRG) is an advanced electrical grounding method designed to limit fault current in industrial and commercial power systems, offering enhanced safety and operational reliability.

✅ Limits ground fault current to safe levels, reducing arc flash and equipment damage.

✅ Improves system uptime by allowing continued operation even in the event of a single ground fault.

✅ Supports fault detection and coordination with grounding and bonding systems.

Grounding and Bonding and the NEC 250 Training

Electrical Grounding and the CE Code Training

Request a Free Power Quality Training Quotation

By connecting the system's neutral point to the ground through a neutral ground resistor, HRG restricts fault current to a low, manageable level during ground faults. This reduces the risk of equipment damage, minimizes downtime, and protects against dangerous conditions such as arc flash energy and arcing ground faults. HRG systems are particularly beneficial in environments where continuous operation is critical, as they enable the detection and localization of faults without interrupting the entire system. This method is a preferred solution in modern electrical distribution, striking a balance between safety and system efficiency.

Frequently Asked Questions

What Is High Resistance Grounding, and How Does It Work?

HRG is a system that connects the neutral point of an electrical power system to the ground through a neutral ground resistor. This resistor limits the current during an arcing ground fault, reducing the risk of equipment damage and increasing system reliability. Unlike solidly grounded systems, which allow high fault currents, HRG systems maintain low fault currents, making it easier to detect and locate ground faults without shutting down the entire system.

In HRG systems, when a fault occurs, the neutral voltage rises, allowing fault detection equipment to identify the issue. These systems work well with detection techniques such as how to check if an area is grounded. The key component, the neutral ground resistor, is designed to handle the fault current until the fault is cleared.

What Are the Advantages of Using High Resistance Grounding in Electrical Systems?

One of the main benefits of HRG systems is their ability to limit arc flash energy during faults. In solidly grounded or ungrounded systems, ground faults can generate high fault currents, resulting in hazardous conditions such as phase-to-phase faults and substantial equipment damage. By using HRG, the fault current is controlled, minimizing the chance of catastrophic failures and improving safety for personnel.

Another advantage is continuous operation. Since HRG systems limit the fault current, they enable the system to continue running during a fault, providing operators with time to safely locate ground faults and address the issue without incurring costly downtime. This makes HRG especially valuable in grounding systems where shutting down the power supply could lead to significant financial losses.

HRG also reduces stress on the system, improving equipment longevity. By limiting fault currents, the wear and tear on electrical components are minimized, reducing the risk of damage during faults.

How Does High Resistance Grounding Differ from Other Methods?

HRG differs significantly from both solidly grounded and ungrounded systems. In a solidly grounded system, the neutral is directly connected to the ground, allowing for large fault currents during a ground fault. While this method provides good fault detection, the high fault currents can cause extensive damage.

In contrast, ungrounded systems lack a direct connection between the neutral and the ground. This can lead to unpredictable fault conditions, where fault currents fluctuate, causing difficulty in ground fault detection and increasing the risk of insulation breakdown and multiple faults.

HRG systems strike a balance by using a resistor to limit fault current, reducing the risks associated with both methods. In terms of energy delivery, HRG interacts with the system’s apparent power, maintaining balance during faults.

What Types of Electrical Systems Are Best Suited for High Resistance Grounding?

HRG systems are ideal for capacitive load scenarios and earthing of industrial and commercial power systems, particularly where line-to-neutral loads are minimal. Industrial settings, such as manufacturing plants, chemical facilities, and power generation plants, benefit from HRG due to the need for continuous operation and safety during fault conditions.

In these environments, HRG helps prevent hazardous situations, such as arcing ground faults, which can lead to equipment failure and injuries. By reducing the fault current, HRG systems protect expensive machinery and ensure that operations continue even when a fault is detected. High-resistance grounded power systems are particularly useful in industries where electrical faults can lead to fires or explosions.

What Are the Maintenance and Monitoring Requirements for High Resistance Grounding Systems?

To ensure that an HRG system functions properly, regular maintenance and monitoring are essential. This includes inspecting the neutral ground resistor for signs of wear or damage, ensuring it functions correctly to limit fault current.

Monitoring includes evaluating apparent power vs. real power to track system stability, as well as routine testing of fault detection systems. These checks are vital to ensure the electrical grounding infrastructure remains reliable over time.

Maintaining HRG systems requires attention to fault-detection equipment, like ground fault relays, which should be calibrated to ensure precise fault detection. Proper monitoring allows for early fault detection, minimizing downtime and preventing damage to equipment.

High resistance grounding systems offer significant advantages for industrial and commercial power applications. By limiting fault current and controlling arc flash energy, HRG systems enhance safety, reduce the risk of damage, and allow operations to continue during fault conditions. Compared to solidly grounded and ungrounded systems, HRG offers a balanced solution that minimizes both the risk of high fault currents and the unpredictability associated with ungrounded systems.

For industries where operational continuity and safety are crucial, high-resistance grounding is the ideal solution. Regular maintenance and monitoring ensure the system operates correctly, enabling the quick detection and resolution of faults. As a result, high-resistance grounded power systems remain a trusted and effective method for fault protection in modern electrical distribution networks.

Related Pages

PPE Performance – NFPA 70E Compliance

PPE performance in arc flash protection is measured by arc rating, indicating the level of thermal energy the gear can withstand. It helps ensure worker safety by selecting PPE rated for specific incident energy levels.

Request a Free Training Quotation

What Is PPE Performance?

PPE Performance: The effectiveness of personal protective equipment (PPE) in safeguarding workers from hazards, particularly its capacity to resist thermal energy during incidents like arc flashes, quantified by arc ratings (cal/cm²).

-

✅ Arc Ratings: Indicate the energy level PPE can withstand before causing burns, measured in cal/cm².

-

✅ Testing Standards: PPE is evaluated using standards like ASTM F1959 and IEC 61482 to ensure protection against arc flash hazards.

-

✅ Material Selection: High-performing PPE utilizes flame-resistant materials like Nomex or Kevlar to maintain integrity under heat.

Whether you’re an electrician or a safety manager, understanding these factors empowers you to make informed choices for workplace safety. Explore arc flash PPE requirements that shape how gear is evaluated is critical to ensure compliance with industry standards.

PPE performance hinges on its capacity to shield workers from thermal energy during an electrical explosion. The key metric is the arc rating, which indicates how much energy (in cal/cm²) the PPE can absorb before a burn injury becomes likely. For example, gear rated at 4 cal/cm² suits low-risk tasks, while 40 cal/cm² handles high-hazard scenarios. Two measurements define this rating:

-

Arc Thermal Performance Value (ATPV): The energy level at which there’s a 50% chance of a second-degree burn.

-

Energy Breakopen Threshold (EBT): The energy at which the material tears open, exposing the wearer.

High-performing PPE uses materials like Nomex or Kevlar, which resist flames and maintain integrity under heat. These fabrics balance protection with comfort, ensuring workers can move freely. It also depends on proper fit and maintenance—worn-out gear loses its effectiveness. To understand how performance aligns with hazard levels, check out our guide on arc flash PPE categories.

How Is Arc Flash PPE Performance Tested?

Performance is validated through rigorous testing to ensure it protects workers from thermal energy during electrical explosions. Industry standards like ASTM F1959 and IEC 61482 guide these tests in controlled labs that simulate real-world arc flash events, such as a 480V panel failure. The process measures how well PPE resists heat, flames, and energy transfer, determining its arc rating—the energy (in cal/cm²) it can withstand before causing a burn.

Testing involves several steps:

- Thermal Exposure: PPE samples face an electric arc, mimicking high-energy incidents.

- Energy Assessment: Sensors calculate heat penetration to assign an Arc Thermal Performance Value (ATPV) or Energy Breakopen Threshold (EBT), ensuring protection against burns or material failure.

- Durability Check: Inspectors verify the gear resists tearing, melting, or igniting under stress.

- Wearability Evaluation: Some tests assess breathability to balance safety with comfort.

For example, a jacket rated at 25 cal/cm² must block enough energy for Category 3 hazards without compromising integrity. These tests align with safety regulations, but compliance starts with understanding broader standards. The rigorous testing behind PPE effectiveness is rooted in NFPA 70E PPE requirements, ensuring gear meets workplace needs. Regular maintenance, like inspecting for damage, preserves performance over time.

Choosing High-Performing PPE

Selecting PPE starts with a hazard analysis, identifying the risk at your worksite. Low-risk tasks (e.g., Category 1, 4 cal/cm²) need lightweight gear like arc-rated shirts, while high-risk jobs (e.g., Category 4, 40 cal/cm²) demand advanced protection. For extreme hazards, a 40 cal arc flash suit exemplifies PPE designed to withstand intense energies, using multi-layer fabrics for insulation.

Performance isn’t just about arc ratings. Consider these factors:

- Material Quality: Nomex offers flame resistance, while Kevlar adds durability.

- Fit and Comfort: Loose PPE reduces protection; heavy gear can cause fatigue.

- Layering: Combining arc-rated layers can boost performance only if each piece is compliant.

Before buying, check labels for arc ratings and NFPA 70E certification. A poorly fitted or damaged piece fails to perform, so inspect the gear regularly. Comfort matters, too—breathable fabrics prevent overheating during long shifts, ensuring workers stay protected without sacrificing productivity.

Quick Reference

Performance has three pillars: arc ratings, rigorous testing, and smart selection. Start with a hazard analysis to pinpoint your cal/cm² needs, then choose gear that balances protection with wearability. Visual tools can simplify this process, especially for teams juggling multiple risk levels. A quick way to compare requirements is by reviewing the arc flash PPE requirements chart, which outlines protection levels by category.

Frequently Asked Questions

Why is performance important for protection?

This refers to how well personal protective equipment resists hazards like heat, flame, and electrical energy during an electrical explosion. High-performing PPE, tested to NFPA 70E standards, can prevent severe injuries by reducing burn severity and protecting against thermal exposure. Employers must adhere to NFPA 70E PPE Requirements to ensure workers are equipped with appropriate protective gear for electrical hazards.

How is PPE tested and rated?

PPE is tested using methods like ASTM F1959 to determine its Arc Thermal Performance Value (ATPV), measured in calories per square centimetre (cal/cm²). This rating tells you how much energy the gear can absorb before causing second-degree burns, helping ensure that clothing is appropriate for the specific electrical hazard.

What factors affect the long-term performance?

Protective clothing performance can degrade over time due to repeated washing, UV exposure, contamination, and mechanical wear. Regular inspections and proper maintenance are critical to ensure that flame-resistant fabrics and arc-rated clothing continue to meet safety standards during use.

Related Articles:

Is Voltage Dropping in Your Power System?

Voltage dropping refers to a reduction in voltage as current flows through a circuit. It can lead to equipment inefficiency, overheating, and performance issues. Common causes include undersized wires, long cable runs, and aging infrastructure, all of which increase resistance.

Power Quality Analysis Training

Request a Free Power Quality Training Quotation

What is "Voltage Dropping"?

Voltage dropping is more than a minor inconvenience—it’s a power quality issue that affects the performance, safety, and efficiency of electrical systems. Recognizing the symptoms and understanding the root causes are essential for maintaining a reliable infrastructure. Learn how to identify and address wiring issues that contribute to voltage problems in our guide to the causes of voltage drop

✅ A gradual voltage reduction due to circuit resistance

✅ Causes flickering lights, motor failure, or overheating

✅ Signals power quality issues or poor wiring design

What Causes Voltage Dropping?

Voltage dropping typically results from resistance in conductors, poor connections, overloaded circuits, or aged infrastructure. As current flows through a conductor, part of the electrical energy is converted to heat, reducing the voltage available at the load. Key contributing factors include:

-

Undersized wiring or conductors

-

Long-distance cable runs without compensation

-

Corroded or loose terminals

-

High-resistance splices or connectors

-

Overloaded circuits or imbalanced phases

Environmental factors, such as temperature fluctuations and humidity, can also exacerbate the problem over time by increasing resistance and degrading materials. For hands-on troubleshooting, try our voltage drop calculator to quickly estimate the loss in your system.

Symptoms of Voltage Dropping in Electrical Systems

Voltage drops often manifest in subtle yet telltale ways. Common symptoms include:

-

Flickering or dimming lights

-

Motors that fail to start or run slower than normal

-

Heating devices that don’t reach full temperature

-

Intermittent resets or shutdowns in sensitive electronics

-

Unexpected tripping of breakers or protective devices

These symptoms are especially prominent during periods of peak load or in buildings with older wiring infrastructure. Left unaddressed, they can lead to long-term damage or premature failure of electrical equipment. Explore the voltage drop formula to gain a deeper understanding of how conductor size, distance, and load impact system performance. If you're working with DC circuits, see our in-depth article on DC voltage drop calculation.

How Voltage Dropping Affects Equipment and Infrastructure

When voltage consistently falls below the required operating level, electrical devices draw more current in an attempt to compensate for the shortfall. This overdraft can cause:

-

Overheating of motors and transformers

-

Reduced energy efficiency and higher operating costs

-

Shortened lifespan of sensitive devices

-

Increased risk of equipment failure and fire

In commercial and industrial facilities, voltage drops can disrupt production processes, interfere with automation systems, and increase downtime. For residential systems, it can damage appliances and lead to safety hazards.

Monitoring and Preventing Voltage Dropping

Effective monitoring is the first step toward preventing voltage dropping. Facilities should regularly inspect for:

-

Voltage fluctuations during load peaks

-

Signs of overheating at connections

-

Degradation in power-sensitive equipment

To mitigate voltage dropping, consider the following preventative strategies:

-

Use properly rated conductors for the application and load

-

Limit the length of wiring runs where possible

-

Regularly inspect and tighten electrical connections

-

Balance loads across phases in three-phase systems

-

Install voltage regulators or power conditioners for critical equipment

For systems with long cable runs or high current demands, a professional power quality assessment can help identify systemic causes and recommend corrective action. By monitoring system performance, maintaining wiring integrity, and applying preventative measures, facility managers and electricians can avoid costly downtime and keep equipment running at peak efficiency.

Related Pages

IEP News

IEP Media

IEP Articles From ET Magazine

Compatibility Issues with Generator-Backed Power Systems

While both UPS systems and generators serve as safeguards against power disruptions, their integration isn't always seamless. Understanding these compatibility concerns is crucial for ensuring reliable backup power and avoiding damage to sensitive equipment.

Visit Our UPS Systems Study Course

Voltage and Frequency Stability

Generators, particularly smaller portable models, may not provide the same level of voltage and frequency stability as utility power. Line-interactive UPS units are designed to operate within a specific input voltage and frequency range. Wide fluctuations outside these tolerances can trigger the UPS to switch to battery frequently, draining reserves and potentially causing premature battery wear.

Synchronization Issues

When power from a generator is restored, there may be a phase shift or momentary mismatch in frequency compared to the UPS output. This lack of synchronization can lead to a disruptive transfer process, potentially causing a brief outage for the connected equipment.

Harmonic Distortion

Generators, especially lower-quality models or those under non-linear loads, can introduce harmonic distortion into the electrical waveform. This 'noise' in the power supply can affect the operation of sensitive electronics connected to the UPS and degrade overall power quality.

Strategies for Improved Compatibility

UPS Selection: Look for line-interactive UPS models with wider input voltage and frequency tolerance ranges. Some may offer a 'generator mode' that accommodates greater fluctuations.

Generator Quality: Whenever possible, opt for generators with better voltage regulation and lower harmonic distortion. Inverter-based generators generally provide cleaner output than conventional models.

Generator Sizing: Overloading a generator can lead to unstable output. Ensure the generator's capacity comfortably exceeds the anticipated load demand.

Isolation Transformers: In specific cases, an isolation transformer between the generator and UPS can improve compatibility by filtering out some harmonic distortion and stabilizing the voltage.

Double-Conversion UPS: A More Forgiving Solution

While the steps outlined above can improve compatibility, double-conversion online UPS systems are inherently better suited for use with generators. Here's why:

Complete Isolation: Double-conversion UPS units continuously convert incoming AC to DC and back to AC, creating a clean and regulated output regardless of generator power quality.

Wider Tolerance: These UPS systems often have wider acceptable input voltage and frequency windows, handling generator fluctuations without issue.

Considerations When Connecting a Line-Interactive UPS to a Generator

UPS Runtime: If frequent generator power deviations cause the UPS to switch to battery often, runtime will be reduced for longer outages. Assess the stability of your generator to gauge this risk.

Load Sensitivity: Less critical equipment can often tolerate generator-powered line-interactive UPS output. Highly sensitive systems might warrant a double-conversion UPS for cleaner backup power.

Neutral Bonding: Proper grounding practices are vital, especially in a generator-UPS setup. Improper neutral bonding can lead to dangerous stray currents and equipment damage.

Additional Tips

Consult Manufacturer Recommendations: Always refer to the instructions for your specific UPS and generator for guidance on compatibility and best practices.

Regular Testing: Periodically test the switchover between the generator and UPS power under load. This helps identify potential issues and ensures backup systems work as intended when needed.

Integrating line-interactive UPS systems with generators requires attention to power quality and synchronization. While choosing suitable equipment and implementing mitigation strategies improves compatibility, double-conversion UPS systems offer superior inherent resilience against generator power fluctuations. Organizations can design robust power protection schemes that ensure uninterrupted operation even during extended outages by carefully considering backup power needs and equipment sensitivity.

Line-Interactive UPS in Scalable IT Infrastructure

In the evolving landscape of IT infrastructure, reliable and flexible power solutions are paramount. Scalable line-interactive Uninterruptible Power Supply (UPS) systems provide an essential service to growing IT networks by adapting to increasing power demands without the need for complete system overhauls. This adaptability ensures that businesses can expand their IT capabilities while maintaining protection against power interruptions and fluctuations.

Visit Our UPS Systems Study Course

Scalability and Its Importance

Scalability in a UPS context refers to the ability to increase the UPS capacity to handle higher loads as demand grows. This is particularly crucial for businesses experiencing rapid growth or those planning for future expansion. The scalable nature of certain UPS systems allows for the addition of more power modules within the same infrastructure, thereby accommodating growth without significant downtime or large-scale replacements.

Advantages of Scalable UPS Systems

Cost Efficiency: Implementing a scalable UPS system is cost-effective over time. Businesses can invest in what they need today, knowing that the system can grow with their requirements. This staged investment helps manage cash flow better compared to investing in a large system upfront.

Reduced Downtime: The modular design of scalable UPS systems allows for expansions and upgrades to be performed with minimal impact on ongoing operations. This is vital for maintaining high availability and reducing the risk of downtime during upgrades.

Enhanced Flexibility: With scalable systems, IT managers can customize the UPS to meet the exact needs of their network, adjusting for power load, redundancy requirements, and runtime. This flexibility also extends to maintenance and servicing, as individual modules can be serviced or replaced without shutting down the entire system.

Long-term Reliability: Scalable UPS systems are designed to accommodate future technology changes and increases in demand. This foresight ensures that the UPS system remains reliable and effective over a longer period, thereby protecting the IT investment as the business landscape evolves.

Implementation Considerations

When planning to implement a scalable UPS system, several factors need to be considered:

Initial Assessment: Accurately assessing current power needs and future growth projections is crucial to selecting a UPS with appropriate scalability options.

Space Planning: Scalable UPS systems require strategic placement as expansions will necessitate additional space. Planning for this during the initial setup phase is essential.

Budget Allocation: While the initial cost of a scalable UPS may be higher than that of a fixed-capacity system, the long-term savings and benefits often justify the investment.

In the dynamic landscape of IT infrastructure growth, the scalability of line-interactive UPS systems presents a significant advantage. By enabling organizations to match power protection to current needs while retaining expansion capabilities for the future, scalable UPS solutions ensure reliable power, optimized investment, and minimal disruptions during inevitable periods of growth.

Scalable line-interactive UPS systems represent a smart choice for growing IT networks, offering a flexible, reliable, and cost-effective solution that grows alongside business needs. As IT infrastructure becomes increasingly critical, investing in a UPS system that can adapt to changing demands is an essential strategy for future-proofing IT operations and ensuring continuous power protection. This approach not only supports operational continuity but also aligns with the strategic growth objectives of modern businesses.

Securing Critical Infrastructure: The Role of Line-Interactive UPS

UPS (uninterruptible power supply) systems are essential for protecting critical infrastructure in healthcare and finance. They provide backup power in the event of a power outage, ensuring that sensitive equipment and data are protected. Line-interactive UPS systems are a popular choice for these applications, offering a number of advantages over other types of UPS systems.

Visit Our UPS Systems Study Course

Benefits of Line-Interactive UPS Systems

Line-interactive UPS systems offer a number of benefits over other types of UPS systems, including:

Lower cost: Line-interactive UPS systems are typically less expensive than other types of UPS systems, making them a more cost-effective option for businesses on a budget.

Smaller size: Line-interactive UPS systems are also smaller than other types of UPS systems, making them ideal for applications where space is limited.

Lower maintenance: Line-interactive UPS systems require less maintenance than other types of UPS systems, making them a more hassle-free option for businesses.

Types of Line-Interactive UPS Systems

There are two main types of line-interactive UPS systems: standby and online. Standby UPS systems only provide power when the primary power source fails, while online UPS systems provide continuous power, even during power outages.

Standby UPS systems are typically less expensive than online UPS systems, but they also offer less protection. They are a good choice for applications where the risk of a power outage is low.

Online UPS systems are more expensive than standby UPS systems, but they offer more protection. They are a good choice for applications where the risk of a power outage is high, such as hospitals and data centers.

Performance of Line-Interactive UPS Systems

The performance of a line-interactive UPS system is determined by a number of factors, including:

Power output: The power output of a UPS system is measured in VA (volt-amps). It must be sufficient to power the equipment it is protecting.

Runtime: The runtime of a UPS system is the amount of time that it can provide power during a power outage. The runtime of a UPS system is determined by the size of its battery.

Efficiency: The efficiency of a UPS system measures how much power it loses during conversion. A more efficient UPS system will lose less power and be more cost-effective to operate.

Technical Considerations

There are a number of technical considerations that must be taken into account when selecting a line-interactive UPS system, including:

Input voltage: The input voltage of a UPS system is the voltage of the power source that it is connected to. The input voltage of a UPS system must be compatible with the voltage of the power source.

Output voltage: A UPS system's output voltage is the power it supplies to its connected equipment. It must be compatible with the voltage of the equipment it is protecting.

Frequency: The frequency of a UPS system is the rate at which it converts power. The frequency of a UPS system must be compatible with the frequency of the power source.

Across the healthcare and financial sectors, where the consequences of downtime range from inconvenient to life-threatening or financially devastating, line-interactive UPS systems play a silent but vital role. Their ability to provide clean power, instant backup, and facilitate safe shutdown procedures acts as an indispensable insurance policy for critical infrastructure. As power grids evolve and technologies advance, the integration of UPS protection will remain deeply intertwined with maintaining resilience and reliable service delivery in these vital sectors.

Battery Advancements and the Impact on Line-Interactive UPS

Advancements in Battery Technology and Their Impact on Line-Interactive UPS

Line-interactive uninterruptible power supply (UPS) systems play a crucial role in ensuring power continuity for sensitive electronic equipment. Serving as a safeguard against power disruptions, these systems seamlessly switch to battery backup during outages, preventing data loss, equipment damage, and downtime. Recent advancements in battery technology, particularly lithium-ion batteries, have significantly influenced the capabilities and performance of line-interactive UPS systems.

Visit Our UPS Systems Study Course

Lithium-ion: The Emerging Choice

Lithium-ion (Li-ion) batteries, widely known for their use in laptops and electric vehicles, are increasingly finding their way into UPS systems. Here's how they stand out:

Higher Energy Density: Li-ion batteries pack more energy into a smaller and lighter form factor compared to lead-acid counterparts. This translates to space-saving UPS units or more runtime within the same footprint.

Longer Lifespan: Li-ion batteries boast more charge/discharge cycles than lead-acid batteries. This could mean less frequent battery replacements over the lifetime of the UPS system, reducing maintenance costs.

Faster Recharge Times: Li-ion batteries generally recharge faster, contributing to quicker recovery times between outages.

Efficient Operation: Reduced internal resistance leads to greater efficiency in charging and discharging, thus minimizing energy losses.

Considerations and Trade-offs

Cost: Currently, Li-ion-based UPS systems typically carry a higher initial price tag compared to those using lead-acid batteries. However, the total cost of ownership over time may be comparable or even favorable due to their longevity and lower maintenance.

Management Complexity: Li-ion batteries sometimes require more sophisticated battery management systems (BMS) for safe and optimal operation.

Safety: Certain Li-ion chemistries, if mishandled, have greater potential for thermal runaway than traditional lead-acid batteries. Reputable manufacturers prioritize robust design and safety measures in their Li-ion UPS units.

Other Battery Advancements

Enhanced Lead-Acid Batteries: Developments like Thin Plate Pure Lead (TPPL) and Absorbed Glass Mat (AGM) technologies have improved lead-acid battery performance in areas like cycle life, recharge times, and tolerance to temperature fluctuations.

Alternative Chemistries: Flow batteries, sodium-ion batteries, and more offer unique characteristics potentially relevant to specific UPS use cases.

The Impact on Line-Interactive UPS

The integration of advanced battery technologies into line-interactive UPS designs brings about notable implications:

Compact Designs: Smaller batteries open up possibilities for more streamlined and space-efficient line-interactive units, particularly valuable in edge computing and cramped network closets.

Increased Reliability: Longer battery lifespan and resilience towards environmental conditions enhance UPS system reliability overall.

Extended Runtimes: Depending on the application, advanced batteries may unlock longer backup times on smaller line-interactive units.

Eco-Friendliness: Li-ion batteries have the potential for greater recyclability than lead-acid options, minimizing environmental impact at end-of-life.

Choosing the Right Battery Technology

The optimal battery choice for your line-interactive UPS depends on several factors:

Criticality of the Load: For highly critical applications, the added longevity and performance of Li-ion batteries often justify the cost.

Space Constraints: Where installation space is extremely limited, the compactness of Li-ion solutions becomes a major advantage.

Environmental Conditions: If the UPS is in a less temperature-controlled environment, the robustness of newer lead-acid technologies or some advanced options might be preferable.

Budget: If the initial purchase cost is the primary driver, a traditional lead-acid line-interactive UPS may still be the most practical solution.

The advancements in battery technology are transforming the landscape of line-interactive UPS systems, enhancing their efficiency, reliability, and sustainability. As lithium-ion batteries continue to evolve and decrease in cost, they are expected to become the standard choice for new UPS installations, offering significant advantages over traditional battery technologies. Organizations looking to upgrade or install new UPS systems should consider the long-term benefits of lithium-ion batteries, despite the initial higher investment, to ensure reliable and efficient power backup solutions.

FREE EF Electrical Training Catalog

Download our FREE Electrical Training Catalog and explore a full range of expert-led electrical training courses.

- Live online and in-person courses available

- Real-time instruction with Q&A from industry experts

- Flexible scheduling for your convenience

Sign Up for Electricity Forum’s Electrical Transformers Newsletter

Stay informed with our FREE Electrical Transformers Newsletter — get the latest news, breakthrough technologies, and expert insights, delivered straight to your inbox.