Electrical Short Circuit

By R.W. Hurst, Editor

An electrical short circuit occurs when current takes an unintended path with low resistance, resulting in excessive heat, arc faults, or increased fire risks. Proper circuit protection, insulation, and grounding methods are vital for preventing damage.

What is an Electrical Short Circuit?

An electrical short circuit is an abnormal condition in which electricity bypasses normal wiring paths, causing high current flow and serious hazards.

✅ Results in overheating, arc faults, or fires

✅ Requires protective devices and grounding for safety

✅ Demands inspection, risk assessment, and prevention

This dangerous event can result in power outages, damaged appliances, or even fires. By understanding the types of short circuits, their causes, detection methods, and prevention strategies, we can greatly reduce the risks. When studying short circuits, it is helpful to first understand the principles of basic electricity, as the same laws of voltage, current, and resistance explain why faults occur.

Causes of Short Circuits

There are several reasons why a short circuit may occur. Common causes include faulty appliance wiring, loose wire connections, and damaged insulation on wires. These issues can lead to current flowing through an unintended path, creating a short circuit.

Short circuits happen for many reasons, ranging from everyday wear to unusual accidents:

-

Damaged or faulty wiring – Insulation breakdown from age or overheating.

-

Water or moisture ingress – Flooding, leaks, or humidity can allow current to bypass insulation.

-

Pest damage – Rodents chewing wiring can strip insulation and create direct shorts.

-

Mechanical damage – Nails, drilling, or physical stress on cables.

-

Corrosion in connections – Loose or corroded joints create hot spots and unintended paths.

-

Appliance defects – Internal failures in motors, compressors, or electronics.

-

Ground faults vs. short circuits – A short is current between conductors, while a ground fault involves current leaking to earth.

-

Overload vs. short – Overload is too much current for too long; a short is a sudden surge with very low resistance.

Detection and Symptoms

Detecting a short circuit can be challenging, but some common signs may indicate its presence. Detecting a short circuit can be difficult, but common warning signs include:

-

Frequent tripping of breakers or GFCIs

-

Flickering or dimming lights

-

Buzzing or crackling sounds in outlets

-

Burning smells or discolored outlets

-

Damaged insulation or melted wires

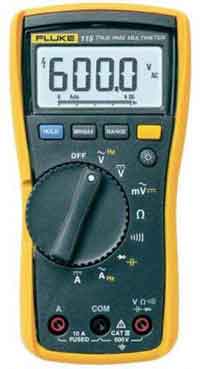

For diagnosis, electricians use multimeters, insulation testers (meggers), clamp meters, and thermal imaging cameras to isolate fault locations. Tracers can also help locate hidden shorts inside walls. In three-phase systems, a fault between conductors can cause even greater hazards, making it essential to understand how three-phase electricity behaves under fault conditions. Ground faults are often confused with shorts, but a true electrical fault may involve multiple types of abnormal current flow.

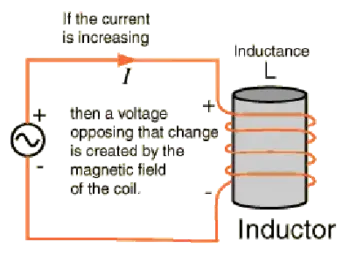

Theory of a Short Circuit

A short circuit illustrates Ohm’s Law (V = I × R): when resistance (R) drops close to zero, current (I) increases dramatically. This sudden fault current stresses wiring, overheats insulation, and can exceed equipment ratings. That’s why time-current curves, protective relays, and properly sized conductors are crucial for safety. Protective devices are designed to limit current and prevent excessive electrical resistance heating that can trigger a fire.

Prevention

Prevention is key to safety. Prevention is the most effective protection. Strategies include:

-

Installing arc fault circuit interrupters (AFCIs) to detect dangerous arcs.

-

Using fuses, breakers, and GFCIs for fault interruption.

-

Adding surge protectors to handle transient spikes.

-

Ensuring proper conductor sizing and insulation quality.

-

Using protective relays and redundancy in industrial systems.

-

Regular inspections of cords, outlets, and panels.

Modern codes, such as the National Electric Code (NEC), the Canadian Electric Code, and IEC standards, all require specific protection and device ratings to reduce hazards.

Dangers of Short Circuits

Short circuits can pose significant risks to both people and property. They are among the most dangerous faults:

-

Fire hazards – Sparks and overheated wires ignite flammable materials.

-

Electric shock – Fault currents may flow through people during contact.

-

Equipment damage – Motors, appliances, and electronics can be severely damaged or destroyed.

For example, a refrigerator's shorted compressor can ignite nearby insulation, while an industrial panel's short can trip upstream breakers, causing outages and costly downtime. They are one of the many dangers of electricity that electricians must guard against through the use of insulation, grounding, and protective equipment.

How To Repair

If you suspect a short in the power system, it's crucial to address the issue immediately. If you suspect a short:

-

Shut off the power at the breaker or unplug devices.

-

Inspect outlets, cords, and panels for visible damage.

-

Use diagnostic tools to isolate the faulted loop.

-

Replace damaged wires or devices.

-

If uncertain, consult a licensed electrician — shorts are not DIY-friendly.

Difference Between a Short Circuit and an Open Circuit

While both short circuits and open circuits involve disruptions in normal functioning, they are fundamentally different. A short occurs when the current flows through an unintended path, resulting in a sudden surge in current. In contrast, an open path is a break in its continuity, which stops the flow of current altogether. Both situations can cause problems in your system and should be addressed promptly.

Frequently Asked Questions

Can a short circuit happen in a GFCI outlet?

Yes. GFCIs protect against ground faults, but not all types of shorts. Breakers and fuses are still required.

How often should wiring be inspected?

Residential wiring should be inspected every 5–10 years, or immediately if signs of overheating or frequent breaker trips are observed.

What is the difference between a ground fault and a short circuit?

A ground fault involves current flowing into earth, while a short occurs between conductors. Both are hazardous.

Understanding shorts — their causes, detection, prevention, and associated risks — is crucial for safeguarding people and property. Regular inspections, proper protection, and adherence to codes all reduce hazards. If you suspect a short, act immediately and contact a qualified electrician.

Related Articles